(70 products available)

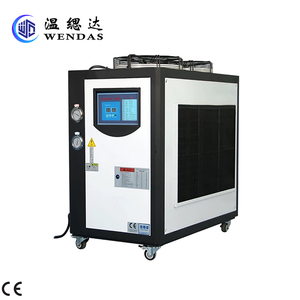

An air-cooled chiller is a machine that displaces heat from a process or from the environment by using air as the cooling medium. The Wenzhou air-cooled chiller is one of the most widely used cooling systems due to its simple mechanism and easy installation.

The Wenzhou air-cooled chiller comes with distinct specifications depending on varying industrial needs. Below are some key specs for consideration.

For optimal performance, it is important to regularly maintain the air cooler. Routine maintenance ensures the chiller has an extended lifespan, consumes less energy, and has efficient cooling. Regardless of the specific design, a consistent maintenance program is vital for the success of the air-cooled chiller. Below are some common maintenance tips for chillers:

The air-cooled industrial chiller is commonly employed by numerous industries due to its simple technology and versatility. Here are some of its applications in different industries.

Food and Beverage Industry

The Food and Beverage industry deals with perishable products that need to be preserved. Therefore, it requires a reliable cooling system. Air-cooled chillers are used to cool the areas of the industry where products are manufactured and stored to maintain the required temperatures. Also, they are applied in the area of the industry where drinks are produced. By doing this, the quality of products is ensured, and the shelf life is prolonged.

Pharmaceutical Industry

In the Pharmaceutical industry, it is essential to maintain precise temperature control for the optimal production of temperature-sensitive products like drugs, vaccines, and chemicals. Air-cooled chillers can provide this control, contributing to protecting product integrity and ensuring compliance with regulatory standards.

Plastic Injection Molding

Air-cooled chillers are extensively used in plastic injection molding processes. They effectively cool the injection molding machines, molds, and extruders to maintain precise temperature control during molding. This ensures efficient molding solidification, reduces cycle times, and enhances the dimensional accuracy and surface quality of molded plastic parts.

Medical Facilities

Air-cooled chillers can be utilized in various healthcare applications within medical facilities. They cool and climate-control spaces such as operating rooms, patient rooms, waiting areas, and laboratories to provide a comfortable environment for patients and staff. Additionally, air-cooled chillers can support the cooling needs of medical equipment and devices, ensuring their proper functioning and preventing overheating.

Data Centers and IT

Data center infrastructure often includes a centralized cooling system for the entire facility. This may consist of large air-cooled chillers that provide the primary cooling source for the entire data center. While a single chiller may be sufficient to cool the entire facility, it highly depends on the product's cooling capacity and the data center's cooling requirements.

Business needs analysis

Industry type, project scale, budget, etc.

Cooling capacity

To meet the actual demand, consider factors such as load requirement, operating environment, etc.

Energy efficiency

Opt for models with high energy efficiency to reduce operating costs and environmental impact.

Overall quality

Pay attention to the materials, manufacturing process, and reliability of the equipment to ensure long-term stable operation.

Brand reputation

Choose well-known brands to ensure quality and service.

Installation and maintenance

Ensure proper installation and timely maintenance to enhance the chiller's performance and lifespan.

Noise level

Consider the noise level to avoid causing pollution in the use environment.

Frequency of use

For equipment used infrequently, consider choosing a μοντελο that is easy to operate and cost-effective.

Safety performance

Understand the safety features of the equipment, such as protection devices, emergency systems, etc.

Usability

Consider the usability of the equipment, such as control methods, display interfaces, etc.

Flexible customization options

Some suppliers offer customization options to provide solutions that better meet specific business needs.

Warranty and after-sales service

Understand the warranty period and after-sales service of the equipment to ensure timely support and maintenance when needed.

Q1: How long does a Wenzhou air-cooled chiller last?

A1: A durable, well-maintained air chiller can last 12 to 15 years or more.

Q2: Does a Wenzhou air-cooled chiller take a lot of electricity?

A2: Larger, older, or less-efficient chillers use more electricity. A typical 50-ton chiller might use around 35 kW per ton. A rule of thumb is that a chiller will consume about 70% of its full load power. Calculate the chiller's full load power to estimate its power consumption. Then consider efficiency, as coolers with variable frequency drives (VFD) and more advanced technologies will chill with less energy.

Q3: Can a Wenzhou air-cooled chiller be relocated if demand changes?

A3: Yes, relocatable chillers can be taken to new sites if required. They are built with transportable frames and connection points.

Q4: Is it OK to put water in the air-cooled chiller's condenser?

A4: No, only refrigerant is allowed inside the condenser. The refrigerant works by vaporizing from heat rather than using water to absorb it.

Q5: Are single scroll compressor chillers safer than conventional R-22 chiller chillers?

A5: Yes, single-screw compressor chillers with R-410A refrigerant are considered safer and better for the environment than older R-22 chillers, which leak harmful substances into the air. R-410A does not deplete the ozone layer.