(3360 products available)

A tube vulcanizing machine performs tube repair by applying heat and pressure to cure the patch. The tube is placed inside a vulcanizer with a heating element controlled by a thermostat. The machine may have other attachments, such as a compressor to inflate the tube during curing. Tube vulcanizing machines are available in manual and automatic operation in several sizes.

Manual tube vulcanizing machines have manual levers and controls to operate the heating element and the pressure used to cure the patch. Users apply the pressure manually and adjust the temperature with manual controls. The same is true for smaller portable versions of the manual vulcanizing machines. These smaller machines are mobile versions often used for on-the-go repairs and are ideal for repairing bicycle tubes.

In comparison, the manual models are more suitable for commercial use where larger tires need to be repaired, such as with the motorcycle, automotive, or heavy-duty trucks industry. These machines provide an efficient and cost-effective way to repair inner tubes instead of replacing them entirely.

In semi-automatic models of the vulcanizing machine, some actions are performed automatically, such as pressure application or heating element control. Full automation allows the operator to program the temperature and pressure for specific repairs. safet

Advanced tube vulcanizing machines have multiple features. For example, they may have dual-temperature control panels, additional patch trays, and quick-release clamps for safety and efficiency. The machines can have multiple tray sizes to cater to different tire sizes, with the dual-temperature control allowing the operator to adjust the heat for different types of tubes and patches. In some models, the clamp is replaced with a locking mechanism to provide a tight seal and prevent any leaks.

Safety features are critical in heavy-duty vulcanizing machines to ensure operator and equipment safety. Safety guards and emergency stop buttons are standard features to prevent accidents. Other safety features include over-temperature protection and pressure relief valves to prevent overexerting pressure and overheating.

A tire tube vulcanizing kit includes all the necessary items required for tire repairs. These kits usually include a vulcanizing machine, patches, clamps, and a repair cement bottle. The patches are used to cover the damaged part of the inner tube, while the repair cement ensures the damaged part is firmly held. A combination of a repair kit and the vulcanizing machine makes tire repairs easy and efficient.

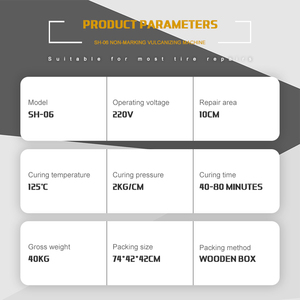

These are some general specifications one can find in most tube vulcanizing machines.

Vulcanizing pressure

The vulcanizing machine applies precise pressure to the tube using clamps or a hydraulic system, ensuring effective valve repair and sealing. The vulcanizing machine's applied pressure promotes a strong bond between the patch and the tube by evenly distributing the heat. The tube's vulcanizing pressure may vary depending on the size and type.

Vulcanizing temperature

The vulcanizing machine operates at specific temperatures to facilitate tube repair. This temperature ensures effective repair by activating the adhesive and promoting a strong bond through tube vulcanization. The vulcanizing temperature may vary depending on the machine model and manufacturer specifications.

Heating source

The heating element of a vulcanizing machine provides consistent and uniform heat for effective tube repair. Heating sources may come in electric heating elements, resistance wires, or steam kettles, among other options.

Machine Size

Vulcanizing machines come in different sizes, such as 10, 12 14 and 16 inches, to accommodate various tube sizes and repair requirements. They provide options to repair tubes ranging from small ones commonly used in bicycles to larger ones used in vehicles and heavy equipment.

Material

The vulcanizing machine is usually made of sturdy and corrosion-resistant materials, ensuring durability and a long lifespan. The machines may be made from aluminum, high-strength steel, or stainless steel alloy, which has excellent thermal conductivity. This feature ensures the machine heats the tube uniformly for an effective repair.

The power supply for electric machines

For electric tube vulcanizing machines, the power supply delivers the necessary power to operate the heating element and other electrical components. It usually connects to a standard electrical outlet with a specific voltage and amperage rating.

These maintenance tips ensure optimum performance.

Regular cleaning

Operators should frequently use a soft cloth, mild soap, and water to clean the vulcanizing machine, removing dirt and grime. Cleaning the machine prevents material buildup from affecting performance, helping maintain a clean work area.

Lubrication

The moving parts of the tube repair vulcanizing machine, such as chains and bearings, should be regularly lubricated. Operators can apply appropriate lubricants to ensure smooth operation and reduce wear and tear.

Routine inspection

The operator should regularly inspect the vulcanizing machine for damages or loose parts. During inspection, the operator can notice and promptly address repair needs to prevent more serious damages, ensuring effectiveness and safe operation.

Electrical Safety

For tube vulcanizing machines with electrical components, operators should ensure that electrical connections are secure, preventing issues related to electric shocks. They should also check insulation to avoid equipment malfunction.

The tube vulcanizing machine is mainly used in the tire repair industry and other manufacturing industries for solidifying rubber. In the tire repair industry, the vulcanizing machine is used to repair punctured areas of tires effectively. This ensures that the tire remains intact and can continue to be used without the risk of further damage.

In addition to its primary use in the tire repair industry, the tube vulcanizing machine has a wide range of applications in various manufacturing industries. For instance, in the rubber manufacturing industry, the machine is used to produce rubber products such as seals, gaskets, and hoses that require high durability and strength. Similarly, the footwear industry relies on the vulcanizing machine to manufacture footwear products such as rubber boots and sandals.

Moreover, the tube vulcanizing machine can be used in the automotive industry to repair not only tires but also other rubber components such as hoses and belts. These components also require the same level of durability and strength as automotive tires. Additionally, the vulcanizing machine can be used in the medical industry to repair medical equipment that is made of rubber.

Because of its ability to produce solid and long-lasting products, the tube vulcanizing machine has become an essential piece of equipment in many industries. Without it, manufacturers would struggle to produce high-quality rubber products or effectively repair rubber components.

There are several factors business buyers should consider when looking for tube vulcanizing equipment for their customers.

Demand analysis

Firstly, buyers should analyze the market demand. They should determine the tube types and sizes their customers commonly use and the tube-vulcanizing sets preferred by their customers. Also, consider the tubes' materials and the repair quality their customers require. By understanding the customers' needs, buyers can identify the most in-demand tube vulcanizing machines and set, ensuring they offer products that are likely to sell quickly.

Technology

Another factor to consider is the technology the vulcanizing machine employs. Customers may prefer machines that use modern technologies such as computerized controls, automatic steam generation, or digital monitoring systems. These advanced features enhance precision, efficiency, and ease of use, making the vulcanizing process more streamlined and effective. Buyers should also look for machines with additional functions, such as patching or sealing capabilities or those that offer diverse repair programs.

Quality and durability

A buyer should look for a reliable and durable tube vulcanizing machine. A good-machine ensures quick and efficient repairs and prolonged service and minimal maintenance. Buyers can identify sturdy vulcanizers that can withstand constant use to meet customers' needs.

Compatibility with existing equipment

Check whether the tube-repairing machine is compatible with other workshop equipment. For seamless operation and optimal performance, many workshops use specialized tools and equipment. Furthermore, a compatible device may have a spare part availability that simplifies the most crucial repair process.

Q1: What are the benefits of using tube vulcanizing machines?

A1: Tube vulcanizing machines offer several benefits. They ensure uniform curing of the repair material, leading to stronger and more durable repairs. The machines also provide consistent and controlled application of heat and pressure, enhancing the quality of the repairs. Using tube vulcanizing machines can significantly improve the productivity of repair operations. Additionally, they allow for the repair of tubular tires rather than replacing them, which is more cost-effective.

Q2: What types of tube vulcanizing machines are available?

A2: Several types of tube vulcanizing machines are available. The manual tube vulcanizing machine is a common one that requires manual operation. Another is the automatic or semi-automatic vulcanizing machine, which offers automated processes for increased efficiency. Separate units for handling the heating and pressurizing aspects are available, known as non-integrated vulcanizing machines.

Q3: What should buyers consider when purchasing tube vulcanizing machines?

A3: When purchasing tube vulcanizing machines, buyers should consider the capacity of the machine to determine if it meets their repair volume requirements. They should also evaluate the heating methods available, such as electric or steam heating, and consider the machine's pressure control features. Additionally, buyers should assess the machine's build quality, availability of spare parts, and repair service to ensure long-term performance and support.