Understanding the Tool Holder

A tool holder is an essential component in any workshop or manufacturing environment, designed to securely hold various tools and equipment in place. From drill bits to chisels, the right tool holder ensures that tools are easily accessible and safely stored, helping to improve efficiency and workflow.

These devices are available in various forms, each catering to specific tools and applications. By choosing the right type of tool holder, users can protect their tools from damage and maintain organization in their workspace.

Types of Tool Holders

- Drill Chuck: Commonly used in drills, these holders grip the shank of drill bits securely to enable precise drilling.

- Collet Chuck: Perfect for milling operations, collet chucks use a sleeve that compresses around the tool, providing high precision and grip.

- Magnetic Tool Holder: Ideal for garage or workshop walls, these holders use magnets to secure tools for easy access while keeping the workspace tidy.

- Pneumatic Tool Holder: Designed for use with air-powered tools, these holders allow for quick changes and tool release without manual effort.

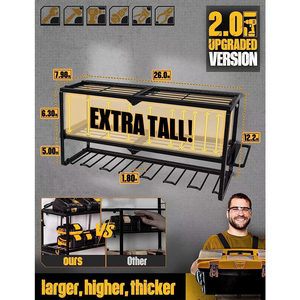

Function and Features of a Tool Holder

The tool holder serves various critical functions in a workspace. Its features are specifically designed to enhance user experience and tool longevity:

- Secure Retention: Tool holders provide a reliable grip on tools, preventing accidents and ensuring safety during operation.

- Easy Accessibility: Tools held on vertical or magnetic holders are always within reach, allowing for quicker work processes.

- Space Optimization: By utilizing wall space with magnetic or pegboard holders, tool holders help keep work areas organized and clutter-free.

- Material Variety: Tool holders can be made from materials such as steel, aluminum, or high-density plastics, each chosen for durability and specific applications.

Applications and Advantages of Tool Holders

Tool holders find extensive applications across various industries and environments. Their advantages contribute significantly to improved productivity:

- Manufacturing: Tool holders are critical in CNC machines, ensuring tools are held with precision to maintain product quality.

- Home Workshops: For DIY enthusiasts, organizing tools with holders means reduced downtime looking for tools, enhancing creativity and project completion.

- Automotive Repair: In auto shops, tool holders arrange wrenches, screwdrivers, and other hand tools for quick access during repairs.

- Safety: Proper tool storage reduces the risk of damage to tools and prevents accidents, promoting a safer working environment.