(6500 products available)

A TC cutter is a tool used for cutting various materials. It is made of tungsten carbide, known for its hardness and durability. TC cutters are commonly used in industries such as manufacturing, construction, and mining for cutting metal, wood, rock, and other materials. They come in different shapes and sizes to suit different cutting needs and are designed to provide efficient and precise cutting performance. Below are some common types of TC cutters:

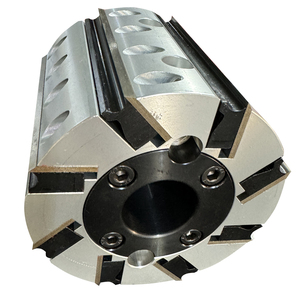

End mill cutter

This type of cutter is used for milling. It has multiple teeth on its cylindrical surface, allowing it to cut while moving forward and sideways. End mill cutters come in various shapes, such as flat, ball, and corner radius.

Taper cutter

Taper cutters have a slightly conical shape with sharp edges along their sides. They're mainly used for creating tapered holes or slots in workpieces.

Fret saw blade

Fret saw blades are small and thin, resembling a musical instrument's fret saw. These blades excel at intricate cutting tasks, including curves and detailed designs. They find applications in woodworking and crafting, where precision cutting is essential.

Spiral cutter

Spiral cutters have helical edges that wrap around the blade's circumference. This design reduces cutting resistance, allowing for smooth and efficient cuts. Spiral cutters are ideal for cutting soft materials like foam and rubber.

Band saw blade

A band saw blade consists of a long, continuous loop with teeth along one edge. Band saw blades are versatile and can cut curves, straight lines, and irregular shapes. They're used in woodworking, metalworking, and food processing industries.

Hacksaw blade

Hacksaw blades have small, sharp teeth designed for cutting hard materials like metal and plastic. They come in various tooth sizes to suit different cutting tasks. The hacksaw frame holds the blade under tension, enabling precise cuts.

Adjustable T.C. Cutter:

Designers make the adjustable T.C. cutter with an adjustable diameter. It can fit different sizes of pipes. It is helpful in many applications. The body is strong. It is usually made of steel or iron. It has a knob or screw mechanism to change the size. There are sharp teeth on the cutting head. They are made of tungsten carbide. They can cut through tough materials. Some designs add a lubricant reservoir. It helps the cutting action and extends the tool's life.

Fixed Die T.C. Cutter:

The fixed die T.C. pipe cutter design has a cutting mechanism that is not movable. It is for cutting pipes of a specific diameter. The compact design makes it easy to use in small spaces. It has a cylindrical body with a fixed cutting edge. The cutting edge has sharp carbide inserts for durability and cutting efficiency. Some fixed die cutters also have a waste removal system. It makes the cutting process cleaner and safer.

Battery-Powered Pipe Cutter:

This design uses a rechargeable battery to power the cutting mechanism. It is very useful for cutting pipes in places with no electricity. The body is often made of lightweight materials like aluminum or high-grade plastic. It reduces user fatigue and increases portability. It has a powerful motor that drives the cutting blade. The blade usually has tungsten carbide or high-speed steel. They can cut tough materials quickly. The design has a comfortable grip handle and controls for easy operation. It may also have features like an LED work light to illuminate the cutting area and safety guards to prevent accidental contact with the blade.

Metal working

T C cutters are used to mill metal surfaces, slots, and gears. They are used in machine shops to create parts for engines, tools, and other equipment. For example, a TC cutter can mill a complex gear profile needed for a transmission system.

Tool production

Tool makers use T C cutters to produce cutting tools like drills, end mills, and inserts. These tools are critical for various industries. A T C cutter can shape the hard material that makes up a drill bit meant for cutting through tough materials.

Aerospace industry

In the aerospace industry, T C cutters are used to manufacture aircraft components. They can create intricate designs on turbine blades, fuselage parts, and other critical components. The precision of T C cutters ensures that the parts are light and strong, which is vital for flight safety and efficiency.

Mold and die fabrication

In mold making, T C cutters shape the molds and dies used in injection molding and stamping. These molds produce plastic parts for consumer electronics, automotive components, and more. T C cutters can create the smooth surfaces and fine details needed for these complex molds.

Woodworking

T C cutters are used to shape and finish wood products. They are used in furniture making, cabinet construction, and flooring. A T C cutter can create decorative edges on a tabletop or shape the interlocking profiles of hardwood flooring.

Construction industry

The construction industry also uses T C cutters for concrete and masonry work. They are used to cut tiles, stones, and concrete slabs. When equipped with the right blade, a T C cutter can make clean cuts in tough concrete, helping in building roads and bridges.

Mining industry

In mining, T C cutters with wear-resistant tips are used to cut rock and mineral exploration. They can maintain sharpness while cutting through hard rock, allowing miners to discover new resources efficiently.

When choosing a t c cutter for business use, several factors must be considered to ensure that the right cutter is selected for the job. Here are some points to consider:

Material selection:

The material to be cut is one of the most important factors when choosing a T.C. cutter. Different materials require different types of cutting tools. For softer materials like aluminum, cutters with high-speed steel (HSS) or carbide tips are suitable. Harder materials such as stainless steel or hardened steel require cutters made from tougher materials like carbide or Cobalt-alloyed HSS.

Cutting conditions:

Consider the cutting conditions in which the tool will be used. Factors such as cutting speed, feed rate, and depth of cut influence the type of T.C. cutter needed. If the cutting conditions are demanding and require high speeds, a cutter with a wear-resistant coating or made from solid carbide may be necessary.

Tool life and cost:

Higher cutting tools may have a higher initial cost but offer longer tool life and cost-effectiveness in the long run. It is essential to find a balance between the two, considering the budget and the expected usage.

Manufacturer and quality:

Choose T.C. cutters from reputable manufacturers known for their quality products. Well-known brands invest in research and development to produce cutting tools with better performance, durability, and consistency.

Special features:

Look for any special features that may benefit the specific application. This could include features such as chip control, non-stick coatings, or specialized geometries for specific materials.

Q1. What is a T&C cutter?

A1. A T&C (Tool and Cutter) sharpener is a machine that sharpens cutting tools. It uses an abrasive wheel to restore the edges of various cutting tools.

Q2. How does a T&C cutter work?

A2. The T&C cutter works by rotating an abrasive wheel against the tool's edges. It grinds to reshape and sharpen the worn edges of the cutting tool.

Q3. What are the types of T&C cutters?

A3. There are two types of T&C cutters - the universal T&C cutter and the CNC T&C cutter. While the former is manually operated, the latter is automatically operated using CNC technology.

Q4. What are the benefits of using a T&C cutter?

A4. The T&C cutter can extend the life of cutting tools. It improves their performance and reduces the need to replace expensive tools frequently.

Q5. What types of tools can a T&C cutter sharpen?

A5. T&C cutters can sharpen a wide range of tools, including end mills, drills, reamers, and face mills, among others.