(3580 products available)

A shoe sole injection molding machine comes in various types. Each type has specific advantages and uses.

Die Casting Injection Molding Machine:

Typically, a die casting injection molding machine creates product parts by pouring molten metal into a closed die. It usually has two halves that open and close to release the material. Nonetheless, the die casting injection molding machine can also use a shoe sole injection molding. This machine can make very complicated parts with high precision, durability, and excellent warmth resistance. It usually works well for metals with low melting points, like zinc, copper alloy, and aluminum. They offer the advantage of high-speed manufacturing. They also have excellent accuracy and efficiency.

Vertical Injection Molding Machine:

The vertical injection molding machine has a mold that opens and closes in the vertical direction. This means that the injection unit is above the mold's cavity. Usually, this design makes it easy to insert cores or inserts into the cavity of the mold. It is also easy to remove completed parts. This shoe sole injection molding machine is usually compact and makes it easy to carry out tasks like assembly, insert molding, and over-molding. Some designs also feature a rotation for added capability and efficiency. The vertical injection molding machines use less material and are environmentally friendly.

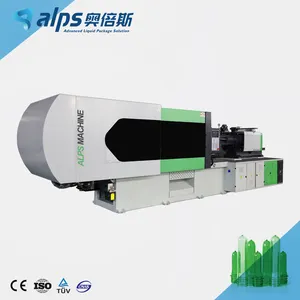

Horizontal Injection Molding Machine:

The horizontal design of the injection molding machine makes it more preferred. This is because it is more advanced technologically and has higher production capacities and efficiency. The horizontal injection molding machine has a large barrel that is positioned horizontally. This allows it to apply the pressure needed to create a complex part. Additionally, when using a horizontal injection molding machine to manufacture footwear soles, the material feeds via a hopper and moves through a heated barrel. Finally, it gets injected into a mold.

Combined Injection Stretch Molding Machine:

Normally, the combined injection stretch molding machine includes an injection unit and an expanded unit. The injection unit transfers molten material to the mold. On the other hand, the expand unit stretches the molded part with the help of pressurized gas or air. This shoe sole injection molding molding machine tech allows for precise control over the production process. It also allows for the quick production of molded parts. The machine is ideal for making footwear molds that need to have high precision and fast turnaround times. It is also suitable for creating complex geometries or large parts.

Shoe manufacturing industry large-scale production

Shoe sole injection molding machines are commonly used in the shoe manufacturing industry to produce shoe soles in large quantities. The advantage of these machines is that they can inject molten materials rapidly and repeatedly into molds to form shoe soles. This allows the production of shoe soles that are consistent in quality and have precise dimensions. Moreover, the machines operate efficiently and can use various materials to meet different requirements, such as durability, comfort, waterproof, etc. Therefore, shoe sole injection molding machines play a crucial role in achieving large-scale, efficient, and quality-controlled production in the shoe manufacturing industry.

Customized production

Shoe sole injection molding machines are also applied in the customized production model. The machine can produce personalized and unique designs for customers by changing the mold design. In addition, the material and color of the shoe soles can also be customized to meet different customer needs. Furthermore, injection molding machines are also suitable for producing small to medium-sized soles, which can reduce the risk and cost of mass production. Therefore, shoe sole injection molding machines provide flexible and creative manufacturing options for the customized production model.

Rapid prototyping and product development

Shoe sole injection molding machines can offer rapid prototyping and product development. Based on the design, specific molds can be made to inject different materials and colors to produce prototype shoe soles. It allows designers and engineers to visualize and assess their ideas and designs in real time. In addition, the rapid production of prototypes can help accelerate the development and testing of new products, speeding up the product launch process and enhancing competitiveness. Therefore, the injection molding machine provides a valuable tool for prototyping and product development.

Industry collaborations and OEM production

Shoe sole injection molding machines also play a vital role in collaborations between different industries and in OEM production. For example, when a particular brand collaborates with another design company to create a limited edition or special series of shoes, they may require unique shoe sole designs that differ from their regular product line. At this point, the injection molding machine can produce the specific shoe soles they need. In addition, when a certain brand outsources its production to another manufacturer, it may require that manufacturer's special technology or production process to achieve specific quality standards and technical requirements. The injection molding machine can meet the brand's distinctive needs through specific molds and production techniques. Therefore, these machines are essential in collaborative projects and OEM production.

When purchasing a new shoe sole making machine, it is crucial to consider the production capacity. Will the machine be able to keep up with the expected demand for shoe soles? Will it have enough pouring capacity to meet the needs of the entire production line?

Next, the sole material compatibility of the machine is crucial for efficient production and cost-effectiveness. The shoe sole injection molding machines are available in various types, each suited to different sole materials. Selecting a machine that aligns with the specific material requirements can streamline the production process and minimize disruptions. Additionally, choosing a compatible machine can help avoid potential issues such as machine-solution incompatibility, material processing limitations, and unforeseen production challenges. Ultimately, investing in a shoe sole injection machine that accommodates the chosen sole material will facilitate smooth and efficient production.

The automation features of a shoe sole molding machine can greatly improve the manufacturing process by streamlining operations and reducing the need for manual intervention. Molding machines with advanced automation capabilities can enhance production efficiency by simplifying setup, minimizing downtime, and optimizing workflow. In addition, automation features such as computer-controlled settings and programmable functions allow for precise control over the molding process, contributing to a smoother and more efficient production line. This ultimately helps to meet the demands of large-scale manufacturing more effectively.

Maintenance requirements need to be considered because the longevity and smooth functioning of the machine will depend on them. Maintenance is an essential aspect that ensures the long-term performance and reliability of industrial equipment, including molding machines. Regular maintenance helps prevent unexpected breakdowns, reduces downtime, and minimizes production disruptions. However, the maintenance requirements of different machines can vary significantly. Some may necessitate frequent, intensive maintenance tasks, while others offer more straightforward, less demanding care routines. Choosing a machine with manageable maintenance demands is crucial to maintaining operational efficiency and minimizing maintenance-related interruptions.

Q1: What types of molds can a shoe injection mold maker use?

A1: Generally speaking, custom metals and alloys are the most common materials for injection molds. They may use various metals in their designs, including steel, aluminum, zinc, and copper.

Q2: What are the benefits of using a shoe sole injection molding machine?

A2: In general, injection molding machines are very efficient production methods for making solid plastic parts. The process is fast, and once set up, the machine can produce thousands of identical pieces per day.

Q3: What capacity good injection molding shoe soles machines have?

A3: Sole molding machines generally have production capacities ranging from 100 to 2,000 pairs of shoe soles per hour.

Q4: What kind of energy-efficient shoe sole injection molding machines are there?

A4: Machines may be hydraulic, electric, energy-mixed, or servo motor. Electric machines are the most energy efficient depending on the nature of their workload.