(194314 products available)

Wood screws have threads that cover most of their shaft lengths. Their tapered heads help them countersink into wooden surfaces. They tightly grip wood, making them less likely to loosen over time. Woodworkers and furniture manufacturers use wood screws to ensure the durability of their work. These screws come in various sizes and finishes to suit different wood applications.

Drywall screws are corrosion-resistant steel fasteners. They come with sharp points that enable easy driving into wall studs or wooden frames. Drywall screws are central to the drywall installation process. They feature a fine-thread design that allows them to be securely fastened. This provides the necessary holding power to wallboard materials.

Sheet metal screws are strong, durable hardware designed primarily for fastening metal sheets. Some of their diverse applications include HVAC systems and automobile manufacturing. Most feature sharp threads that penetrate metal surfaces. Manufacturers make sheet metal screws from materials ranging from stainless steel to brass. The choice of material depends on where the screw is applied and how resistant it needs to be to corrosion.

Machine screws are versatile fasteners used across many industries. Also known as bolt screws, they commonly secure machinery parts and electronic devices. They have uniform threads along their lengths and are made of steel, alloy, or brass. Also, manufacturers make machine screws in various sizes to cater to various needs. Their consistency and durability make them essential for replacing screws in machinery.

Lag screws, also called lag bolts, have heavy-duty construction. They are designed for high-stress applications. These screws feature large, coarse threads that provide superior gripping power in dense materials. Some of their common applications include fastening wooden beams or heavy Furniture. Lag screws are often used in construction projects that require a strong, long-lasting hold.

Screws secure materials like drywall, wood, and metal in construction. Builders use drywall screws to attach panels in framing. They use wood screws in furniture assembly and structural work. Some also use deck screws in outdoor structures for corrosion resistance. In addition, machine screws hold parts together in machinery and equipment. Their role in securing elements shows an increase in demand.

The automotive industry uses screws extensively to assemble and maintain vehicles. Manufacturers choose bolts for wheels and engines because of their strength. They also employ sheet metal screws to fix body components and interior elements. This is because of the fasteners' corrosion resistance. Some automotive maintenance professionals replace worn bolts with new ones. Screws are critical fasteners that offer stability and safety in assembling vehicles in this industry.

Screws secure components and cases in electronics. This makes their role critical in ensuring device integrity. For instance, small machine screws hold delicate parts together in devices like smartphones, laptops, and gaming consoles. In addition, many electronic devices have plastic parts held together by metal or self-tapping screws. These fasteners ensure the devices are properly assembled and function correctly while providing durability.

HVAC systems use screws to install and maintain key components. For instance, sheet metal screws hold ductwork together, ensuring an airtight and efficient system. Also, in the installation of heating and cooling units, manufacturers use lag screws and machine screws to secure heavy parts. These screws ensure they withstand constant vibrations or temperature changes. HVAC maintenance technicians also frequently replace screws to ensure systems remain properly functioning.

Screws come in various materials, each chosen for specific needs. Such applications can include stainless steel, which offers excellent corrosion resistance for outdoor or marine use. Manufacturers use carbon steel for their strength and rigidity and commonly use these screws in indoor applications. The metal chosen impacts the screw's durability, especially in high-stress or exposed environments, making material selection vital for performance and longevity.

Screw drives include slot, Phillips, and Torx to ensure proper installation. Each type of drive has a different advantage. A slotted drive is straightforward but can slip easily. A Phillips drive provides more rotational control and is less likely to cam out. On the other hand, a Torx drive offers excellent grip, reducing driver slippage. This also makes it ideal for high-torque applications. Each drive type has its use, which influences the screw's efficiency.

Screw threading is a vital feature that influences their holding power and easy application. Screws with coarse threads are ideal for soft materials like wood because they bite in and provide a secure grip. Fine threads are better suited for harder materials like metal. This is because they offer a tighter, more secure fit. Additionally, some screws have partially threaded shafts. These help in pulling materials together in specific applications, offering more versatility.

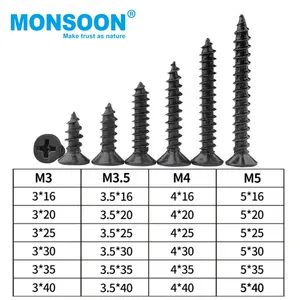

The length and diameter of screws matter as they directly influence the screw's strength and application suitability. A screw's length determines how deep it can go. On the flip side, its diameter affects the size of the hole needed and its overall load-bearing capacity. Choosing the right length and diameter ensures optimal performance and prevents material damage in various applications. That is why reaping these benefits beyond aesthetics and convenience is essential.

Screw material is an important consideration when selecting a screw. Usually, manufacturers make screws from steel. Buyers should note that steel is a preferred option due to its strength and durability. To enhance corrosion resistance, some may also choose stainless steel screws. This is especially the case in outdoor or industrial settings. Other materials include brass and aluminum. While these provide a lighter and more weather-resistant solution.

The ideal length and diameter are crucial for the screw's effectiveness and longevity. The length must be adequate for the application without protruding unnecessary portions. Use of the right diameter prevents the splitting of the base material. Too small a size may compromise stability and result in a loose or stripped hole. Consider both factors proportional to the material's thickness and density for better results.

The screw's thread design significantly impacts its performance. This is especially so for different applications. For instance, coarse threads provide a better grip in softer woods or thicker substrates. Conversely, finer threads work best for dense materials like metals. This is because they ensure a tighter, more secure fit without damaging delicate surfaces. So, consider matching the thread design to the specific needs of the chosen base material.

Screw heads affect not only their driving method but also their visibility and the strength of their hold. For this reason, a countersunk head is better for a flush finish than a rounded head. Moreover, a hex head offers a strong grip for heavy-duty applications, while a Phillips or slotted head is easier to drive. Manufacturers also add multiple head designs with an added benefit. They do this to enhance their versatility across projects.

A1. Screws offer unmatched holding power due to their threaded design, ensuring tight and long-lasting connections. They are also easier to remove and replace than nails or rivets, allowing for more flexibility in assembly and disassembly. Additionally, screws provide greater torque, making them suitable for high-stress applications. Their availability in various materials, lengths, and head types further enhances their versatility across multiple industries.

A2. Wood screws are designed with longer, protruded threads to provide a firm hold in wooden materials. They normally lack deep s. Conversely, drywall screws feature finer threads and a drill point tip. Drywall screws enable easy installation into metal or wooden studs behind drywall sheets. These screws use unique thread designs to cater to their respective applications and materials.

A3. The screw head design influences the tool needed for installation and whether the head will be flush or visible in finished products. For instance, a parapet head is better for flush finishes than a rounded head. Conversely, length impacts the screw's ability to reach deeper layers of material. This makes it critical in ensuring a secure and effective connection. A proper head design and length combination enhances the screw's overall performance.

A4. Many screws are resistant to corrosion, with steel models coated in zinc or other anti-corrosive materials. In addition, stainless steel screws offer superior rust resistance for outdoor or humid environments. The longevity of a screw is influenced by its material, coating, and exposure to environmental elements. Therefore, selecting a screw designed for the specific conditions it will encounter is essential for ensuring durability.