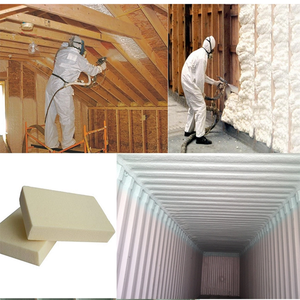

Types of poly iso spray insulation machines

A poly iso spray insulation machine creates a rigid foam insulation product that offers a high R-value per inch of thickness. This insulation is ideal for reducing energy consumption in buildings or structures by erecting energy-efficient barriers. Various pieces of equipment—manifolds, proportioners, hot boxes, pumps, air compressors, and generator sets—are combined to produce these insulations in different types or approaches.

- Mixing Manifold: In-situ insulation application is typically used for irregular shapes. The components are mixed in the spraying head or delivery nozzle. The aim is to achieve a uniform mix, resulting in consistent foam density, growth, and curing rate.

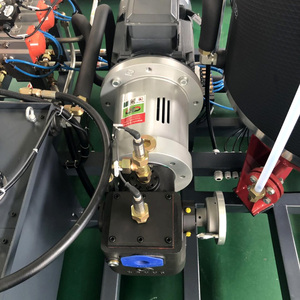

- External Proportioners: They are responsible for the external proportioning of the spraying components. It comprises two distinct separate lines. One is for the isocyanate, and the other is for the polyol/blend. They get heated separately and are pumped to the mixing spray/whip assembly, wherein they are mixed. The external proportioner is typically employed for high-production spraying applications.

- Air Purge Pumps: They are among the common types of pumps. They utilize compressed air for their operation, which subsequently propels the material forward. Air purge pumps are suitable for low and medium-viscosity materials. Their applicability extends to several industries and regions, such as water infrastructure and asset management, distancing and engineering services, residential, social, and public care education, and leisure.

- Electric Pumps: They are also known as electric drive pumps. They are used to spray insulation foam. It is ideal for open-circuit propane heating and low- to medium-viscosity materials.

- Transfer Pumps: They are meant to transfer the liquid material from the drum to the proportioning machine. They are designed for high-pressure pumping applications, making them suitable for handling materials with higher viscosities.

- Air Compressors: They offer the compressed air needed to operate spray foam insulation pumps and different pieces of equipment. They can be of various types and sizes according to the requirement.

- Gas or Diesel Generator Sets: They provide the electricity needed for operating proportioners, heating equipment, and spray guns. They can be of various types and sizes according to the requirement.

Some additional types of machines are as follows:

- Skid-Spraying Machines: This type of machine is utilized for applying insulation to roofs, walls, and other almost horizontal surfaces. The machine is usually mounted onto a skid to provide a firm and sturdy base.

- Mobile Spraying Units: They are also known as a mobile spraying rig. It is a complete, self-contained unit, which is ideal for use on projects or locations where mobile access is generally required. The spraying equipment itself is usually mounted onto a wheeled cart or a mobile frame assembly.

- Air Filtration Systems: These are meant to filter and purify the air emitted from the spray foam equipment, ensuring compliance with environmental regulations and safety standards. They may be included in the spray foam machine or as an add-on component.

Specifications and Maintenance of Poly Iso Spray Insulation Machine

Specifications

- Motor Power: Typically ranging from 10kw to 18.5kw. The higher the motor power, the faster the construction efficiency.

- Pump Pressure: The pumping pressure of the polyurea spray insulation machine directly affects the evenness and thickness of the spraying. Usually, it is within the range of 20-40bar.

- Output: Output refers to the quantity or weight of materials that the equipment can spray in a given period, which influences the speed of construction. The spraying output is typically between 2-6kg/min.

- Nozzle: The nozzle is an important component that affects the spraying effect, including size and shape. Generally, it includes a filter and an adapter. The sizes of them are selectable according to the needs of the project.

- Material: The materials that can be sprayed are varied, such as: rigid polyurethane foam, reinforced polyurethane foam, etc. The equipment should be compatible with different types of materials to meet various project requirements.

Maintenance

- Cleaning: Regularly clean the external surfaces and internal parts of the equipment to keep it clean and free from contamination.

- Lubrication: Apply an appropriate amount of lubricant to the moving parts, such as lubricating oil or grease, to ensure smooth operation and prevent wear.

- Inspection: Regularly inspect key components of the equipment, such as pumps, nozzles, spraying heads, etc., to ensure they are free from damage or blockage, and clean or replace them promptly if needed.

- Maintenance of air compressor: Regularly check the working condition and lubrication of the air compressor connected to the spraying machine to ensure stable air supply and proper functioning.

- Electrical maintenance: Regularly check the electrical connections, switches, and circuits of the equipment to ensure good contact and insulation, eliminating hidden dangers for electrical safety.

Scenarios of poly iso spray insulation machines

The usage of poly iso spray insulation machines spans numerous industries, including construction, automotive, agriculture, marine, packaging, and refrigeration.

- Having good energy efficiency, poly iso insulation spray foam machines are widely used in building constructions. Nonetheless, they are mainly used for energy-efficient roofs and wall assemblies in commercial properties.

- Poly iso spray insulation machines are generally employed in sealing gaps, joints, and permeable materials, so making the vehicles more energy-efficient and lessening the noise level inside the vehicle.

- In the agro-food area, spray foam insulation machines can be used to make customized containers, trays, and other packaging solutions for fruits and vegetables, ensuring their safe transport and preserving their freshness.

- In the marine industry, spray foam insulation machines are mainly used to install polyurea coatings and foams on different marine vessels.

- Refrigeration systems often have poly iso spray insulation machines to be used to improve efficiency, minimize heat exchange, and maintain the desired temperature inside the insulated units, such as refrigerators, freezers, cold storage facilities, and refrigerated transport vehicles.

How to choose poly iso spray insulation machines

Business buyers should consider several factors when choosing a poly iso spray insulation machine for their needs.

-

Production capacity

Production capacity refers to the quantity of insulation material that the machine can generate within a designated time frame. It is usually measured in square footage or meters per hour. It's important for business buyers to pick a machine with a production capacity that aligns with their project requirements and volume. Selecting a machine whose production capacity corresponds with project requirements helps ensure efficiency and timely completion.

-

Material compatibility

Polyurethane foam insulation is composed of two main components: isocyanate and polyol. Certain machines are specifically designed to handle specific components. Therefore, business buyers need to ensure that the insulation spray machine is compatible with the materials they intend to use. Choosing a machine that can accommodate various insulation materials offers greater flexibility and allows business buyers to adapt to changing project demands.

-

Machine performance

Business buyers need to evaluate critical performance aspects of the spray insulation machine, such as spray quality, uniformity, and foam expansion ratio. Buyers should opt for machines that offer adjustable spray pressure and volume, enabling them to achieve the desired insulation result for their projects. The spray pattern and accuracy of the nozzle also play a pivotal role in determining coverage and waste. Therefore, buyers should consider equipment that has precise nozzles to enhance insulation efficiency and minimize material wastage.

-

Ease of use and maneuverability

Ease of use refers to factors like intuitive controls, clear instructions, and effortless setup and maintenance. On the other hand, maneuverability involves considering the machine's weight and dimensions and whether it comes with transport aids like wheels or carts. Selecting an insulation spray apparatus is simple to handle and operate reduces the time and effort expended in insulation applications.

-

Dependency on external factors

Business buyers should assess their operational needs, including project types and volumes, as well as budget considerations, both initial investment and ongoing operating costs. They should also consider the insulation's end-use application and regulatory compliance requirements. Ultimately, to find the ideal machine for business applications, buyers should evaluate the factors and requirements specific to their insulation projects and operational needs.

Poly iso spray insulation machine Q&A

Q: How does a spray foam insulation machine work?

A: The spray foam machine mixes the two components of spray foam insulation in an application gun. Those components are liquid resin and activator. As it is propelled and pumped through the hoses, the two liquids will mix and react, creating a large expanding foam that fills gaps and spaces as it is sprayed.

Q: What types of insulation are in demand in the market?

A: According to a market research report, the global insulation market is growing. The demand for insulation materials in the building and construction sector accounts for a sizeable percentage of market share stock. Polyurethane insulation is in high demand due to its effectiveness and versatility; thus, machines for spraying this type of insulation are in demand, as are the materials they spray.

Q: What specifications of insulation machines are most in demand?

A: Demand is mainly for mobile and compact machines that can easily travel.

Q: Do insulation machines come with accessories?

A: Sometimes, the machine will be offered with or without extras like the heating box, hoses, or spray guns.