(714 products available)

Ready to Ship

Ready to Ship

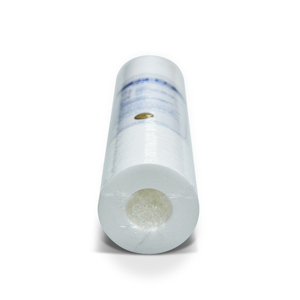

The wholesale pleated water filter comes in various types suitable for different applications. They are designed to remove particles from the water to enhance its quality.

Below are some of the common types of pleated filters along with their brief descriptions:

Polyester Filters

They are resistant to harsh conditions, such as high pressure and temperatures. Also, the pleated polyester filters have great chemical compatibility. So, they can handle highly corrosive fluids during industrial filtration processes.

Polyproylene Filters

These filters are an excellent choice for filtering fluids with high turbidity. They have tighter tolerances to produce consistent and reliable results. The pleated polypropylene filters have good chemical and temperature resistance. They are used to remove impurities from industrial fluids, such as petroleum and air.

Stainless Steel Filters

Stainless steel filters are durable and can withstand harsh conditions. They have excellent structural integrity which allows them to retain their shape even during high-pressure applications. The filters can be cleaned easily. They are suitable for critical filtration applications in the oil and gas industries.

PES/EHS Filters

PES/EHS filters have high flow rates and are often used in biopharmaceutical applications. They have excellent clarity and can efficiently remove particles from liquids and gases. The filters have great air diffusion qualities for optimal gas exchange during sterility applications.

Activated Carbon Pleated Filters

These filters have adsorptive abilities that help remove organic compounds, such as volatile organic compounds (VOCs). The activated carbon filter traps odors and particulate matter to enhance air quality. It also reduces the presence of chlorine in the water and improves the taste.

Coalescing Filters

Coalescing filters are known for their efficient liquid droplet removal capabilities. They can separate oil from water in industrial applications. The filters capture small liquid particles from compressed air to prevent damaging downstream equipment.

Deep Pleated Filters

Deep pleated filters possess a three-dimensional filter structure. This unique design allows them to filter fine particles from the air or liquid. They have a higher dirt holding capacity and can endure more frequent filter replacements.

Pleated water filters come with many features that improve their performance and user experience. These features include;

Pleated filters remove sediment or particles from water. They catch sand, silt, rust, and chlorine while letting water flow through. This protects plumbing and improves water quality. These filters work for point-of-use systems at sinks or appliances and for point-of-entry systems at the whole house. Their large surface areas allow them to trap many different types of particles. Since they can be cleaned, they are more cost-effective than other types. Implementing these filters reduces the chances of equipment damage or issues caused by contaminated water.

Wholesale pleated filters are used in several industries for applications beyond just filtering water. These filters are installed in HVAC systems to improve indoor air quality by removing allergens, dust, pollen, and other airborne particles. Pleated air filters capture tiny particles that impair the comfort of building occupants and visitors. Cleaner air results in enhanced health, productivity, and wellness, which is good for homes, schools, hospitals, offices, and commercial buildings.

Industries use pleated filters for efficient separation and purification in various fluids. Engine oil filters for heavy machinery, vehicles, and engines use pleated tubes to trap contaminants from lubricating oil. These filters promote optimal engine performance by preventing harmful particles from causing wear and tear. They increase the oil's useful life by keeping it clean. Similarly, hydraulic, fuel, and transmission filters use pleating to enhance the filtration of hydraulic fluids, fuel, and transmission fluids respectively. This design optimizes their performance and prolongs their lifespan.

Pleated filters are also used in liquid applications such asautomotiveisas, chemical processing, food and beverage production, manufacturing, and pharmaceuticals. They remove impurities from process liquids to protect equipment and ensure product quality. Pleated cartridges for air filtration systems in residential, commercial, and industrial settings use them for effective removal of dust, pollen, allergens, and other airborne particles.

Wholesale buyers of water pleated filters need to choose filters suitable for their target customers. The following tips can help buyers make the right choice.

Consider Filtration Needs

Businesses should assess the specific applications their customers need filters for, such as home drinking water purification, heavy industrial processes, or chemical separation. Different pleated filters suit different needs, so choosing filters that match the required micron rating, cartridge size, and contaminant removal is essential.

Check Filter Material and Durability

Wholesale buyers must evaluate the filter's media material, overall construction, and quality. While pleated filters offer significant surface area, the material must be suitable for critical applications. For example, using polyester for high-temperature industrial tasks or polypropylene for corrosive fluid environments is best.

Examine Flow Rate and Pressure Requirements

It is essential to determine the required flow rate and pressure for each application. Select filters that allow for adequate flow without causing excessive pressure drop in the system. A filter with great flow capacity will perform well in demanding processes.

Consider Filter Holders or Replacement Cartridges

Some buyers may need to purchase filter holders, while others may need to buy replacement cartridges. Either way, stockholders must ensure that the filters and holders are easy to replace and install to minimize downtime and operating costs for end-users.

Evaluate Cost vs Performance

Buyers need to compare prices against the filter's features, reliability, and efficiency. Choosing filters based on cost alone may ignore durable filters that save money and deliver great performance. Find filters that offer an optimal balance between cost and value over time.

Review Manufacturer Support

Finally, it is essential to have good technical support and after-sales service from filter manufacturers. If there are issues with filter performance or there are questions about selection, prompt assistance can help fix problems and protect the buyer's business. It is essential to choose suppliers who stand by their products and are ready to help when needed.

Q1: What makes pleated filters better than cartridge filters?

A1: Compared to cartridge filters, pleated filters have a larger surface area, which enables them to capture more dirt and extend their lifespan.

Q2: Which method should be used to clean pleated filters?

A2: To remove trapped particles, use tap water to clean the filter. Washing it under the water jet in the opposite direction of the airflow will be great.

Q3: What is the range of micron ratings for pleated filters?

A3: Depending on the specific model, the micron rating can range from 1 micron to 100 microns or even higher. The smaller the micron rating, the greater the dirt accumulation capability.

Q4: Where should pleated filters be installed?

A4: It depends on the application. For air filters, the pleated filter goes into HVAC systems. For water filtration, the filter goes into the housing unit to filter all incoming water.