(25725 products available)

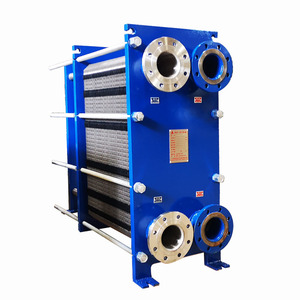

According to the structure form, the plate heat exchanger can be divided into five types:

The gasketed heat exchanger is a plate heat exchanger sealed with gaskets, making disassembly and cleaning easy. The semi-welded heat exchanger is partially welded and gasketed, improving durability. The screw heat exchanger has a screw-shaped plate for high-viscosity fluids. The welded heat exchanger uses laser-welded plates for durability and is gasketless. The double tube heat exchanger uses a double-tube structure with high efficiency and is compact.

The core of a plate heat exchanger consists of plates. The main plate material used is stainless steel to ensure good heat transfer and corrosion resistance. In addition, some plate heat exchangers will use titanium plates or platinum-coated titanium plates, which are more corrosion-resistant and prolonged life expectancy, especially in coastal areas or where the medium contains high levels of chloride. The non-plate parts, such as the frame, brackets, bolts, nuts, and sliding blocks, are mainly made of carbon steel. On some components, the materials may be stainless steel. This is mainly to prevent seepage in places.

Usually, the plates will be packed into a housing or frames. The casing frames must be stainless steel; this not only protects the device but also ensures safe operation without leakage. In addition, the double-tube heat exchangers include two pipes, one external and one internal. The internal pipe transfers heat to the external pipe, which, in turn, transfers it to the external environment. This exchange occurs via the heat transfer medium, such as water, oil, or steam, filling the gap between the two pipes. The double-tube heat exchanger provides a simple structure and convenient manufacturing, but its heat transfer area is small, and it is easy to become clogged, which is suitable for a small flow.

Material concerns aside, after assembly or manufacturing is complete, a plate heat exchanger manufacturer will perform an air test on the unit. In doing so, they will ensure that the unit complies with the standard for leak detection.

Ensuring a plate heat exchanger works efficiently requires attention and maintenance. Regular inspections and routine cleaning are two essential elements that ensure a machine runs smoothly and its lifespan increases. Not only should it be regularly inspected and cleaned, but users must also be aware of what to look for when conducting these two tasks to prevent any unnecessary damage.

Prepare:

Things to Remember:

NOTE: Users should consider the type and quality of water used in the heat exchanger, as impurities can build up, reduce heat transfer efficiency and decrease longevity. As per guidance, it should be cleaned every six months or use deionized water to reduce the risk.

Dairy industry

Milk plate heat exchangers are widely used in the dairy industry for pasteurization, cooling, heating, and homogenization of dairy products. They heat milk to kill bacteria to extend shelf life. After pasteurization, plate heat exchangers cool milk down quickly to the storage temperature. They save energy and maintain the quality of dairy products.

Food and beverage industry

Food and beverage plate heat exchangers are used to process various food and beverage products, such as juices, soups, sauces, and canned goods. For example, in juice production, heat exchangers are used to pasteurize juices to eliminate microorganisms and ensure product safety. In the processing of soups and sauces, heat exchangers are used to sterilize and homogenize the products to achieve uniformity and extend shelf life.

Pharmaceutical industry

Sanitary plate heat exchangers are widely used in the pharmaceutical industry for the sterilization, cooling, and heating of pharmaceutical products. For example, in the preparation of medicine, heat exchangers are used to sterilize and cool down the raw materials to ensure product quality and safety. In the processing of vaccines and biological products, heat exchangers are used for temperature control and concentration to achieve the desired process parameters.

Oil and gas industry

Oil and gas plate heat exchangers are used in the oil and gas industry for crude oil heating, natural gas cooling, and oil refining. For example, in crude oil transportation, heat exchangers are used to heat crude oil to reduce its viscosity and facilitate transportation. In oil refineries, heat exchangers are used for cooling and heating to recover energy and improve refining efficiency.

HVAC industry

HVAC plate heat exchangers are widely used in air conditioning systems, refrigeration systems, and ventilation systems. For example, in central air conditioning systems, heat exchangers are used for heat recovery to improve the energy utilization efficiency of the system. In refrigeration systems, heat exchangers are used for evaporators and condensers to achieve heat transfer and refrigeration functions.

Wholesale buyers can use the following tips when selecting the right plate heat exchanger for their target market:

Understand distinct application requirements

Wholesale buyers should carefully evaluate their business needs to understand their distinct application requirements. They should consider factors such as capacity demands, temperature and pressure ranges, fluid types and potential constraints related to space or energy efficiency. By understanding their specific needs, wholesale buyers can identify the heat exchanger types that are most suitable for their applications, ensuring effective performance and optimal results.

Assess design and technical features

Wholesale buyers need to evaluate the different designs and technical features of plate heat exchangers. They should look at options for materials such as stainless steel, titanium, carbon steel or specialty alloys, as well as different plate geometries like corrugated or patterned plates. Additionally, buyers must consider the units' effectiveness, compactness, flexibility and ease of maintenance. Also, buyers have to ensure that the feature of the heat exchanger matches their customer needs and business model.

Determine compatibility with existing systems

Wholesale buyers need to ensure that the plate heat exchangers they choose are compatible with their customers' existing systems. They should pay attention to the exchanger's dimensions, connections and working parameters. Also, they should consult with the manufacturers if necessary. By ensuring compatibility, buyers can provide their customers with smooth integration and reliable operation.

Evaluate safety and regulatory compliance

Wholesale buyers should choose heat exchangers that prioritize safety and comply with applicable regulations. They need to ensure that the exchanger has relevant safety features such as leak-proof designs, pressure ratings and temperature limits. Moreover, buyers should check the manufacturer's compliance with industry standards and select products that meet quality and safety requirements. In doing so, buyers can ensure their customers' users' protection and reduce potential liabilities.

Supplier's reputation and customer support

When selecting a plate heat exchanger, wholesale buyers should consider the manufacturer's reputation and customer support. They need to research the manufacturer's track record, market presence and product quality. Additionally, buyers should evaluate the suppliers' customer support services such as technical assistance, spare parts availability and warranty terms. Choosing a reputable manufacturer with reliable customer support, buyers can ensure a successful partnership and provide their customers with dependable products.

Q1: What is the plate heat exchanger?

A1: A plate heat exchanger is a type of heat exchanger that uses plates to transfer heat between two fluids.

Q2: What are the benefits of plate heat exchangers?

A2: Plate heat exchangers offer several benefits, including compactness, improved thermal efficiency, ease of cleaning, and flexibility. The plate’s turbulent flow patterns result in better heat transfer, and many models can be disassembled for maintenance.

Q3: Who makes heat exchangers?

A3: There are several heat exchanger manufacturers in the world, and they make distinct varieties of heat exchangers for different applications.

Q4: Which plate heat exchanger to choose?

A4: Choose the plate heat exchanger based on parameter exchange, including pressure dropout, flow rates, temperature, and others. Consult with an expert or manufacturer to select the right unit for specific needs.

Q5: What is the difference between a plate and shell heat exchanger?

A5: The design and configuration of heat transfer are involved. Heat transfer happens in a series of flat plates stacked together in the plate heat exchanger, and it is compact and offers high efficiency. A shell-and-tube heat exchanger consists tubular bundles within a cylindrical shell. It is suited to larger volumes or higher pressures.