(70 products available)

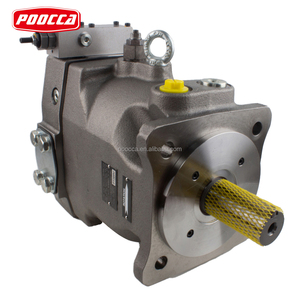

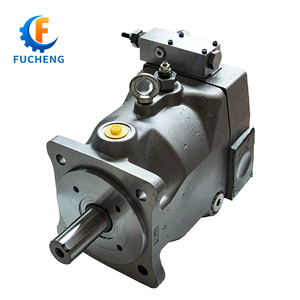

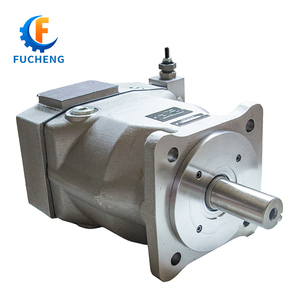

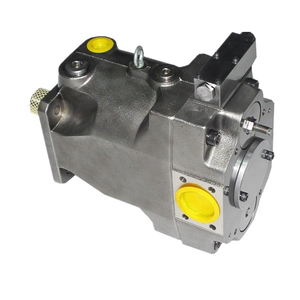

Fixed Displacement Piston Pumps

This hydraulic pump is characterized by the steady flow rate of the pump, which is always constant. Any change in the demand of the hydraulic system will not affect the flow and the pressure of the pump; hence, it provides reliability and predictability for many industrial functions. Fixed displacement hydraulic piston pumps are suitable for those functions that require flow stability rather than varying the flow pressure. These functions include the pressing machine, lifts, and other machinery that run under constant fluid power.

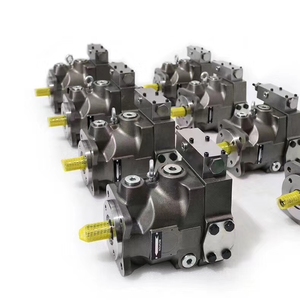

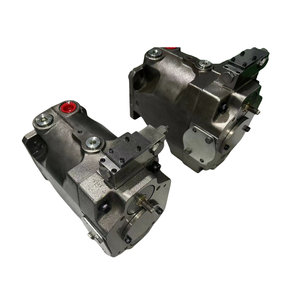

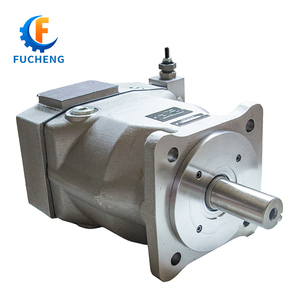

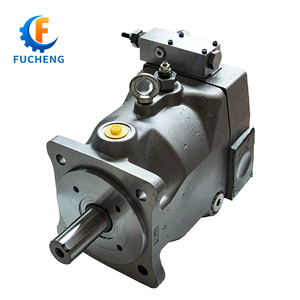

Variable Displacement Piston Pumps

Parker pv63 hydraulic pumps have a capacity for adjusting the flow rate and pressure during operation. They can sense the system requirements and adjust themselves to provide the appropriate amount of fluid power. This feature leads to performance optimization, energy conservation, and cost savings over time. They're normally used in sophisticated systems such as aircraft control, where precision and efficiency are paramount.

Heavy-duty machinery construction

Variable displacement hydraulic pumps are the core components of many construction vehicles, such as excavators, loaders, and bulldozers. These pumps provide the necessary fluid power for lifting, digging, and moving large quantities of earth and materials. Due to their power and versatility, hydraulic pumps help perform critical operations in Construction, including mixing, pouring, and lifting heavy substances within a short time.

Energy Sector Operations

Hydraulic pumps are widely applied in the energy sector, where they're applied in oil and gas extraction processes. They play an important part in drilling operations by providing the necessary pressure to drill deep into the earth. In addition, these pumps are also used in renewable energy systems such as solar tracking systems to adjust the panels for maximum sunlight exposure. Their reliability in extreme conditions makes them essential for energy exploration and production.

Aerospace and Aviation

Hydraulic pumps are critical components in the aviation industry, where they are used in aircraft control systems. For example, they control the movement of wings, flaps, and landing gears, thus ensuring fluid power precision. Parker's variable displacement pump is highly valued for its performance and weight, which is especially important for aircraft design. Hydraulic pumps are also used during testing and validation processes to check aircraft performance and safety.

Manufacturing Automation

Thus hydraulic pump is widely used in various manufacturing systems, particularly in machinery for molding, stamping, and metal shaping. The pumps are also used for controlling robotic arms employed in the assembly sections of workplaces. Due to the fixed flow output, the mechanical precision can be easily controlled, thus enhancing the quality and uniformity. In addition, due to their reliability, durability, and capacity for harsh conditions, they are ideal pumps for the manufacturing industry.

Transportation Systems

Hydraulic pumps used in vehicular braking systems are applied in many transportation systems to ensure safety through braking precision. Parker hydraulic pumps are used in many public transport systems, such as buses and trains, to lift and lower ramps and doors. They also power the steering systems, which enable the drivers to easily turn the wheels. These pumps are durable and reliable to provide the best performance in various environmental conditions.

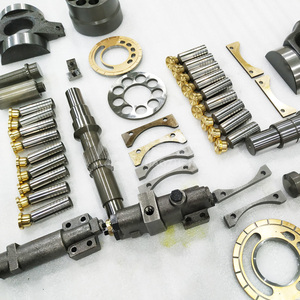

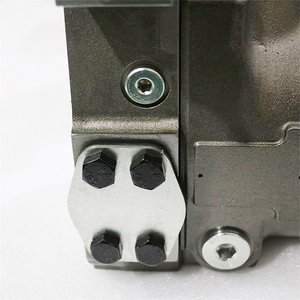

It requires the installation of the following key components: the fitting, pressure line, return line, and the reservoir. A user should first set the pump in the correct position as the motor mount, then attach the drive components. A user should connect the hydraulic lines and other electrical connections before putting in the fluid. For the hydraulic fluid, the user should consult the manufacturer to find the correct kind of fluid. Once the pump is linked to all the components, the user should ensure that all the lines are tightened before priming. Lastly, the user should conduct a test run at low pressure to check for possible leaks and ensure proper functionality.

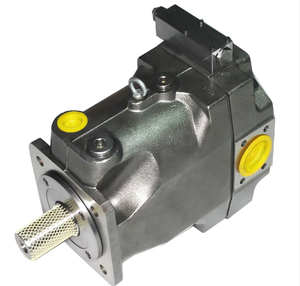

Parker PV63 hydraulic pumps are primarily constructed with premium materials such as ductile iron for pump housings and aluminum alloys for motor components. These materials aid in providing strength and resistance to wear. Their manufacturing process is based on advanced techniques like CNC machining and precision grinding that ensure tight tolerances. The company conducts pressure and performance tests during the manufacturing process to verify each pump meets predetermined specifications. Also, the pumps undergo a series of quality inspections according to the certified ISO 9001 quality management standards to ensure the quality of the final product.

Safety can be improved through various safety measures, including relief valves that prevent overpressure by releasing excess pressure fluid. Some are designed with internal bypass systems that enable the pump to relieve pressure in case of system failure. Others possess temperature sensors that automatically stop the operation of the pump in case of overheating. Hydraulic fluid used in the Parker PV63 hydraulic pumps is integrated with safety measures such as the addition of fire-resistant fluid and non-toxic oils, which reduce the possibility of fire or environmental damage in cases of fluid leakage.

Get the right type of pump

Fixed hydraulic pumps are suitable for simple system applications that require constant fluid flow. In contrast, hydraulic variable displacement pumps are ideal for complex systems because of their ability to adjust flow rates and pressures according to system demands. This selection criterion should be based on the particular application requirements to ensure optimal performance.

Check for compatibility with system components

When choosing a Parker PV63 hydraulic pump, ensure that the pump is compatible with hydraulic fluids used and other system components, such as motor drives. In addition, verify the pump's pressure range to ensure it fits with the system's pressure requirements, as this will prevent the pump from being overworked and enhances operational reliability.

Consider the pump's efficiency and performance

Higher efficiency pumps reduce energy consumption while maintaining optimal performance. Variable hydraulic piston pumps provide efficient operation by adjusting displacement according to workload demands. This helps prevent energy wastage. Select a pump that enables minimal heat generation. This protects system components and extends the life of the hydraulic fluid.

Assess the maintenance requirements

Maintenance was an important consideration when choosing the Parker hydraulic pump. Easy maintenance requirements, such as simple oil changes and accessible parts, reduce system downtime and operating costs. Check for manufacturer support, as there will be a focus on availability, as support will be critical for replacement parts and guidance.

Budget for initial and long-term costs

Buying costs involve the costs incurred to purchase or acquire a hydraulic pump, while long-term costs are the costs that will be incurred during maintenance and operating the pump. Compare the costs and consider the longevity and reliability of the PV63 hydraulic pumps that deliver overall cost-effectiveness.

A1: Parker PV63 hydraulic pumps are engineered to seamlessly function with an extensive range of hydraulic fluids. These include both petroleum-based and specialty bio-derived fluids. For optimal performance, refer to the manufacturer's guidelines, where they specify recommended fluid types. This helps ensure compatibility. Hydraulics recommend periodic checks of fluid conditions and possible replacements with suitable alternatives to ensure the longevity and efficient functionality of the pump.

A2:Some common signs include decreased performance, such as poor pressure or flow, abnormal noises, excessive vibration, and external leakage. Other indicators may include overheating and increased energy consumption. Regularly monitoring these symptoms allows timely identification of the need for replacement.

A3:Hydraulic pumps can last between 10 and 20 years under ideal conditions, including proper installation, routine maintenance, and operating within specified limits. However, other factors, such as the intensity of usage and environmental conditions, affect the durability of the hydraulic pump.

A4:Yes, Parker PV63 hydraulic pumps are appropriate for outdoor use. Their construction using durable materials protects them from adverse weather conditions, including rain and extreme temperatures. In addition, their design features integrate measures against dust and debris.

A5:These pumps comply with ISO and ANSI standards. Such compliance ensures reliable performance and easy integration into existing systems.