(127 products available)

Oval o-ring epdm dynamics are known for their durability, especially because they are made of ethylene-propylene-diene rubber. The EPDM oval o-rings are suitable for sealing applications. It is particularly useful because of its excellent resistance to heat, weather, and ozone. Therefore, it is suitable for use in harsh environments.

Unlike the standard round o-rings, EPDM oval o-rings have an oval cross-section. It provides a more even compression and distribution of pressure in a sealing application. This characteristic makes them particularly useful in applications where a more stable and long-lasting seal is required.

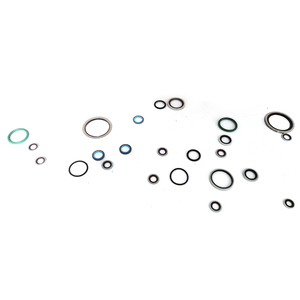

Here are some common types:

Standard EPDM o-ring

The standard EPDM o-ring is round in shape, so it is widely used. It has characteristics such as resistance to heat, chemicals, and weather. Such resistance makes them ideal for numerous sealing applications. The ring comprises EPDM rubber and is in demand in the automotive sector, construction, and industrial machinery due to its sturdiness.

O-rings are mostly used in static sealing applications where they are positioned between two stationary surfaces. These are also applicable in dynamic applications where the component undergoes minimal motion. The standard o-ring is compatible with a wide range of sizes and is used to ensure a uniform and effective sealing solution across different industries.

Oval EPDM O-Rings

The oval EPDM O-rings provide enhanced sealing capability, especially in narrow grooves or slots. Such use is common in specialized engineering applications. The distinctive shape of the oval O-ring enables even pressure distribution across the seal. This characteristic reduces wear and improving the longevity of the seal compared to traditional round O-rings. Oval O-rings are particularly favored in industries where precision engineering is critical, such as aerospace, automotive, and high-tech manufacturing.

Custom-sized EPDM O-Rings

For applications that demand non-standard specifications, custom-sized EPDM O-Rings provide a tailored solution. These O-rings are manufactured in specific sizes as per orders for bespoke applications where standard O-rings may not fit properly. EPDM's inherent resilience and adaptability make it easy for these custom O-rings to adhere to unique design requirements. They are mostly favored in industries such as medical technology and specialized machinery requiring particular sealing dimensions.

Oval EPDM is a type of o-ring that has numerous applications that require a reliable sealing solution. They are also known for their durability, especially in industries that expose them to extreme temperatures, chemicals, and weathering.

Automotive Industry

Automotive industries use oval EPDM O-rings to make window seals, door seals, and under-the-hood components. It is heat-resistant and can withstand automotive environments without any degradation. This is how it maintains its sealing integrity. Since these rings contribute to vehicle durability and performance, they are in demand in the automotive industry.

Construction and Building

The construction industry uses oval EPDM O-rings for window and door seals, and gaskets for roofing. Their weather resistance makes them ideal for sealing applications in buildings and vehicles. They provide effective barriers against water, air, and dust. These rings ensure energy efficiency, reduced maintenance, and prolonged lifespan of structures.

Industrial Equipment

Companies incorporate oval EPDM O-rings in various industrial machinery and equipment, such as pumps, valves, and fittings. They also use the rings to make gaskets and seals for equipment that handles chemicals and exposes high heat. In these cases, the EPDM provides a strong chemical barrier. They ensure longer equipment life and reduce downtime for maintenance. The rings also help maintain operational efficiency in such industrial environments.

Electronics and Electrical Engineering

People use oval EPDM O-rings in electrical enclosures, connectors, and seals to protect against dust, moisture, and other environmental factors. Their ability to create a reliable seal in devices exposed to different elements while maintaining electrical integrity makes them crucial in this industry. It keeps these devices functional and reliable.

Medical and Pharmaceutical

The medical and pharmaceutical industries use these O-rings in lab equipment, medical devices, and pharmaceutical packaging. They are resistant to certain chemicals and sterilization processes such as autoclaving. Therefore, they are suitable for sealing applications where hygiene, durability, and chemical resistance are required. They also contribute to patient safety and the efficacy of medical products.

Oval shape EPDM O-rings are used in many sealing applications in different industries due to their unique sealing properties and strong resistance to different elements. They are important components that play a crucial role in ensuring the integrity and functionality of various products.

Consider the Size and Specifications

It is very important to consider the size and specifications of the o-ring as they will determine the performance of the ring. Just like any other hardware, they come in various sizes. Buyers should ensure they pick one that fits perfectly in their applications. People going for custom o-rings should take precise measurements of the required size. The o-ring supplier should have the expertise to manufacture custom-sized o-rings for optimized performance.

Verify the Chemical Compatibility

People know that EPDM has limitations when it comes to chemical resistance. It does not perform well with hydraulics, oil, gasoline, and any other substance that contains natural or synthetic rubber. Buyers should ensure they find out which other chemicals the o-ring will be exposed to. Validate that the EPDM o-ring is suitable for that environment. This will ensure they maintain their integrity and prolong their life.

Assess the Quality

The quality of the o-ring determines how well it will perform. Buyers should get o-rings from reputable manufacturers known for using high-quality EPDM material. Just like any other hardware, people should ensure they get o-rings that will protect them from future maintenance or replacement. Quality manufacturers usually have the certification to prove the durability and quality of their products. Take a look at them when buying o-rings.

Evaluate Temperature Resistance

EPDM O-rings have temperature ranges where they perform well. It is usually around -40°C to 120°C. Buyers looking for o-rings for extreme environments should validate that their preferred choice can withstand the required temperature. To make the selection process easier, buyers can request the manufacturers to provide them with technical data sheets or brochures. They contain the pertinent information about the o-ring and its working conditions.

Check the Application Suitability

The o-rings for sale are suitable for different applications. Automotive industries use them for door seals, gaskets, and other sealing functions. The lab and medical sector use them for equipment, devices, and sterility maintenance. Construction industries use them for weathering protection, and electrical engineers incorporate them into their devices. Buyers should ensure they get an o-ring suitable for their own industry application to give reliable sealing.

A1:-The shape makes the O-ring easy to install, distribute pressure evenly, and create a tighter and more reliable seal. This ensures that these O-rings perform better than the regular round types.

A2:- The standard oval O-rings are made from EPDM. It is a synthetic rubber that is super tough and flexible. It breaks down slowly when exposed to the elements compared to a regular rubber. This makes them durable for outdoor use.

A3:-No. While they are strong and sturdy, the elements that make up EPDM are hard fuels, oils, and grease. The chemical structure will break down over time, reducing its effectiveness as a seal. This is why fluorocarbon or nitrile rubber is recommended for fuel lines.

A4:-These O-rings are some of the most popular seals because they are durable. They withstand extreme heat, cold, and even ozone. They stick around longer than regular rubber O-rings, especially in harsh outdoor conditions.