(5032 products available)

Ready to Ship

Ready to Ship

Various types of fuel pressure sensors are available, including:

Strain Gauge Fuel Pressure Sensor

Capacitive Fuel Pressure Sensor

Piezoelectric Fuel Pressure Sensor

Inductive Fuel Pressure Sensor

Optical Fuel Pressure Sensor

MEMS Fuel Pressure Sensor

Bimetallic Fuel Pressure Sensor

Thermal Conduction Fuel Pressure Sensor

Magnetostrictive Fuel Pressure Sensor

The most common types of fuel pressure sensors used in automobiles are strain gauge, capacitive, and piezoelectric sensors.

Strain Gauge Fuel Pressure Sensor: This sensor uses an electrical resistance strain gauge that changes resistance when strained. It is widely used in original fuel pressure sensors in internal combustion engines. When fuel exerts pressure on the diaphragm, it strains the gauge and changes its resistance. The ECM sends a current through the strain gauge and measures the resistance change, converting it into a pressure reading. These sensors are low cost and simple, making them the most common choice. However, they can be less accurate and sensitive than other sensor types.

Capacitive Fuel Pressure Sensor: An original fuel pressure sensor uses capacitors whose distance between the plates changes due to fuel pressure changes. The varying capacitance is measured and converted into a pressure reading. These sensors offer high accuracy and stability. As a result, they are suitable for applications that require precise pressure measurements.

Piezoelectric Fuel Pressure Sensor: This sensor contains piezoelectric crystals that generate an electric charge when mechanically stressed. As the fuel pressure changes, it mechanically stresses the crystals and generates a proportional electric charge. This change in charge is measured and converted into a pressure reading. These sensors are highly sensitive and can detect slight pressure changes, making them ideal for applications needing dynamic response and high sensitivity.

These sensors have different specifications depending on their applications. Here are some general specifications of the fuel pressure sensor.

Construction material

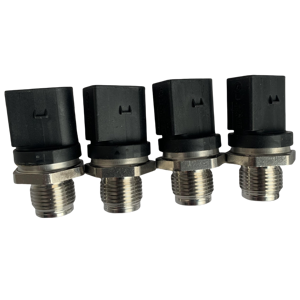

These sensors are constructed with high-quality materials such as steel, aluminum, glass, and ceramics. These materials make the sensors durable and able to withstand harsh conditions such as high temperatures and pressures.

Electrical connection

The original fuel pressure sensor has a standard electrical connector like a Delphi, Denso, or Molex connector. The connector allows for secure and reliable electrical connections with the ECM.

Operating voltage

Most original fuel pressure sensors operate at a voltage of 5V. However, some models use 1V or 12V. The operating voltage is used to power the sensor and allow communication with the ECM.

Output signal

The output signal varies depending on the type of sensor. For example, a voltage output signal from the sensor to the engine control unit indicates variations in fuel pressure. The unit interprets the changes in pressure and makes the necessary adjustments to maintain optimal fuel flow.

Pressure range

The pressure range of the original fuel pressure sensors differs based on the engine requirements. Nonetheless, they can measure pressures ranging from 0 to 300 psi. The sensors can also measure small pressure changes, ensuring the fuel system's stability and accuracy.

Sensing element

The sensing element of the original fuel pressure sensor is usually made of piezoelectric ceramics or silicon. These materials convert pressure changes into electrical signals. They are highly sensitive and provide accurate measurements.

Maintenance of fuel pressure sensors is important to ensure their longevity and prevent costly repairs. Here are some sensor maintenance practices:

Choosing the original fuel pressure sensors for business needs requires careful consideration of several factors to ensure that the selected products meet the desired quality, reliability, and performance standards. Here are some tips:

Before attempting to replace a fuel pressure sensor, it's important to note that as the sensor gets older, it may not be able to send accurate readings. Therefore, if the car's computer has been receiving readings that are not correct, it may be unsafe to drive the vehicle. Always assess the safety risks before handling a car with a potentially faulty sensor.

That said, here are some steps to take when replacing the sensor:

Locate the fuel pressure sensor

The first step is to locate the sensor, which isn't hard to do. The sensor is usually located in the fuel rail, and one can find it by following the fuel line from the fuel tank to the engine.

Disconnect the battery

It's important to disconnect the battery before starting the replacement process. Doing this will help avoid any electrical shorts that may occur during the replacement process.

Relieve fuel pressure

Before removing the old sensor, one must relieve the fuel pressure. To do this, locate the fuel pump relay or fuse and start the engine while disconnecting the relay or fuse. Doing this will make the fuel pressure deplete after a few minutes.

Remove the old sensor

Now that the fuel pressure has been relieved, it's time to remove the old sensor. First, disconnect the electrical connector from the sensor, then use a wrench to unscrew the sensor from the fuel rail.

Install the new sensor

Take the new fuel pressure sensor and apply a small amount of thread sealant to the threads. Then, screw the sensor into the fuel rail and tighten it securely with a wrench. After that, reconnect the electrical connector to the sensor.

Reconnect the battery

Once the new sensor is installed and the electrical connector is reconnected, one can finally reconnect the battery. Make sure the battery terminals are clean and tightened properly.

Check for leaks

Before starting the engine, it's important to check the fuel system for leaks. Wipe down the area around the new sensor with a clean rag, then turn the ignition key to the "on" position without starting the engine. This will prime the fuel system and build pressure. Now inspect the sensor and surrounding area for any signs of fuel leaks.

Start the engine

After ensuring there are no leaks, start the engine and let it run for a few minutes. This will allow the engine to warm up, and users can ensure everything is working properly.

Q1. What is the work of a fuel pressure sensor?

A1. The original fuel pressure sensor detects the pressure of the fuel in the gas lines and sends this information to the engine control unit (ECU). The ECU uses this data to adjust the fuel pressure by controlling the fuel injectors so that optimal fuel combustion occurs in the engine.

Q2. Where is the fuel pressure sensor located?

A2. The original fuel pressure sensor is located on the fuel rail in the high-pressure pipeline. The fuel rail gets water in gas form from the injector and serves as a distribution channel to all fuel injectors.

Q3. How to tell a car has a faulty fuel pressure sensor?

A3. There are several indicators that a vehicle may have a faulty fuel pressure sensor. The first is a drop in engine performance, especially when accelerating. Other signs include poor fuel efficiency, difficulty starting the vehicle, and the check engine light coming on. As a result, the car will jerk or hesitate when accelerating due to an imbalance of air and fuel in the combustion chamber.

Q4. Can one drive a car with a faulty fuel pressure sensor?

A4. While one can drive a vehicle that has a faulty fuel pressure sensor, it is not advisable. This is because the sensor is responsible for maintaining the correct fuel pressure, and if it is faulty, it can cause either a lean or rich fuel mixture. Driving with a lean mixture can damage the engine over time, while a rich mixture can clog the spark plugs and emit excess pollutants through the exhaust.

Q5. How does one replace a faulty fuel pressure sensor?

A5. Contact an expert as DIY may be risky. However, to replace the sensor, the technician will first relieve the fuel pressure, disconnect the electrical connector, and unscrew the old sensor. Then, the new sensor is screwed in, the electrical connector is reconnected, and the system is checked for leaks.