(260608 products available)

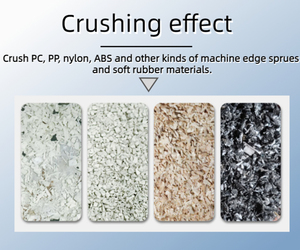

The oem recycle is a crucial component within the realm of industrial machinery, specifically designed for processing plastic and rubber materials. Its primary function is to facilitate the recycling of plastics by thoroughly cleaning and preparing them for reuse. This specialized machinery integrates advanced technologies to effectively wash and decontaminate plastic waste, ensuring that it meets the quality standards required for further processing. The oem recycle is an essential tool in the drive towards sustainable manufacturing practices, helping industries reduce their environmental footprint by promoting the reuse of materials.

There are various types of oem recycle available, each tailored to meet specific industrial needs. Common types include batch washing lines, continuous washing lines, and semi-automatic washing lines. Batch washing lines are typically used for smaller operations, offering flexibility and control over the washing process. Continuous washing lines, on the other hand, are designed for large-scale operations, providing a constant flow of material and maximizing efficiency. Semi-automatic washing lines strike a balance between manual intervention and automation, ideal for medium-sized operations. Each type of oem recycle is engineered to optimize the washing process, ensuring that plastics are thoroughly cleaned and ready for recycling.

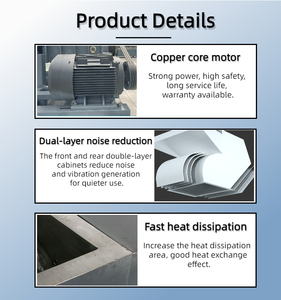

The oem recycle boasts a range of features and functions that make it indispensable in recycling operations. Key features include high-capacity washing tanks, powerful decontamination systems, and efficient drying mechanisms. High-capacity washing tanks allow for the processing of large volumes of plastic waste, while powerful decontamination systems ensure the removal of impurities such as soil, labels, and adhesives. Efficient drying mechanisms, such as centrifugal dryers, help reduce moisture content, preparing the materials for further processing. Additionally, advanced control systems in the oem recycle enable precise monitoring and adjustment of the washing parameters, ensuring optimal performance and quality results.

The construction of a oem recycle involves the use of robust materials and components designed to withstand the rigors of industrial operations. Stainless steel is commonly used for the washing tanks due to its corrosion resistance and durability. The decontamination systems often incorporate high-quality filters and separators to efficiently remove contaminants from the plastic waste. Motors and pumps within the oem recycle are selected for their reliability and power capabilities, typically ranging from 35-40 hp to ensure consistent operation. Conveyor belts and feeding systems are engineered to handle large loads, facilitating smooth movement of materials through the washing process. The choice of materials and components plays a critical role in the overall efficiency and longevity of the oem recycle.

To maximize the benefits of the oem recycle, it is essential to understand its operation and maintenance requirements. Proper use involves selecting the right type of washing line based on the volume and type of plastic waste being processed. Regular maintenance is crucial to ensure the machinery operates at peak performance; this includes routine inspections, cleaning of filters and tanks, and lubrication of moving parts. Training operators on the correct use and maintenance procedures can significantly enhance the efficiency and lifespan of the oem recycle. Additionally, implementing a strict schedule for replacing worn components helps prevent downtime and maintains the quality of the recycled materials. Understanding these aspects ensures that the oem recycle remains a valuable asset in the recycling process.

Choosing the appropriate oem recycle for your industrial needs involves understanding several critical factors. The first consideration is the capacity of the machinery. Depending on the volume of plastic waste your operation processes, you'll need a oem recycle that can handle the load efficiently. Larger operations may benefit from high-capacity models, while smaller facilities might opt for more compact solutions. Another factor is the type of plastic waste being processed. Different plastics have varying levels of contamination, which can affect the choice of washing line. Ensuring that the oem recycle is equipped with suitable decontamination systems is crucial for optimal performance.

Consideration should also be given to the level of automation in the oem recycle. Fully automated systems offer the advantage of reduced labor costs and increased consistency, whereas semi-automatic systems provide greater flexibility and control. The choice between these options should align with your operational goals and the skill level of your workforce. Additionally, the energy efficiency of the oem recycle is an important aspect, as it can significantly impact operational costs. Opting for models with energy-saving features can lead to considerable savings over time.

When selecting a oem recycle, key factors include the capacity, type of plastic waste, level of automation, and energy efficiency. Understanding your specific industrial requirements is essential to make an informed decision that enhances productivity and cost-effectiveness.

The type of plastic waste can influence the choice of oem recycle due to varying contamination levels. Different plastics may require specific decontamination systems, so it's important to choose a washing line that can effectively clean and prepare the materials for recycling.

Essential maintenance practices for oem recycle include regular inspections, cleaning of filters and tanks, lubrication of moving parts, and timely replacement of worn components. These practices ensure the machinery operates at peak performance and extends its lifespan.

Yes, oem recycle can often be customized to meet specific industrial applications. Customization options may include adjustments to capacity, decontamination systems, and automation levels, allowing the machinery to better suit the unique needs of different operations.

Common challenges in operating oem recycle include managing contamination levels, maintaining consistent performance, and optimizing energy efficiency. Addressing these challenges requires careful selection of machinery and adherence to best practices in operation and maintenance.