(50 products available)

A band saw is a machine that cuts with a long, continuous blade in the shape of a band. There are a number of types of wood band saws based on their size, model, functionality, and other specifications.

Based on Size:

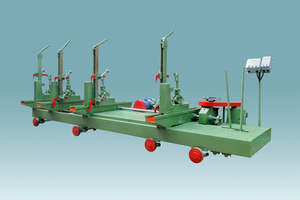

Upright or free-standing bands saws are generally the largest size of Band saws. They usually stand on the floor, and their cutting capacity is also very large. Aside from that, the machine can cut various types of materials. 14 inch band saws are among the most popular choices for both professional and hobbyist woodworkers. The beauty of this mj319 wood bandsaw machine is that it fits well into most workshop spaces without sacrificing cutting power or capacity. Smaller bench-top models are more portable and convenient to store, but they may come with limited abilities and specifications.

Based on Blade Configuration:

A vertical Band saw is a machine where the blade is positioned vertically, and it is easily used to cut wood in curves and circles. What's more, the machine can also be used to cut various other types of materials, including metals, plastics, and mores. The woods tape mj319 also comes in an arc or ellipse-shaped design. The Blade can assist in various cutting tasks such as resawing, ripping, and cross-cutting. Horizontal band saws have the blades positioned in a horizontal direction. They are also sometimes called metal cutting band saws because they are primarily used to cut metals into manageable sizes before machining them into final shapes and forms. This is especially true for production facilities like factories and workshops.A combination band saw is a versatile cutting machine with both horizontal and vertical saw setups in a single unit. With the ability to cut metal and wood seamlessly, it eliminates the need for two separate saws, saving valuable workspace and increasing efficiency.

Capacity

The MJ319 wood band saw can work with lumber up to approximately 16 inches in thickness and 24 inches in width. The actual cutting capacity might vary based on the specific design and configuration of the band saw.

Power

This wood band saw's motor power is measured in horsepower or kilowatts. For MJ319, it is typically around 3-5 horsepower. This translates to about 2.2-3.7 kilowatts. This power determines how thick of a wood it can cut and how smoothly it can do so.

Cutting Speed

Wood band saws operate using a saw blade that moves at a specific speed. This speed is usually measured in feet per minute (fpm) or meters per minute. For the MJ319, the blade speeds are typically around 3,150 fpm (960 meters per minute) or more. The cutting speed affects the saw's ability to make smooth cuts through the wood, and faster speeds are generally better for producing smooth cuts.

Blade Width and Thickness

The MJ319 band saw blades for Woods are available in various widths and thicknesses. The width determines how tight of a curve the saw can cut, while the thickness influences its resilience and rigidity.

Overall Dimensions

The overall dimensions of the MJ319 band saw will depend on the overall size of the saw, including height, width, and depth. Bigger band saws typically have greater dimensions.

Net Weight

Because these saws are designed to handle heavy lumber and make significant cuts, they are usually heavy. The MJ319 wood band saw usually weighs several hundred kg.

Regular Cleaning:

Clean the band saw after use to remove any dust, debris, or wood chips.

Use a soft brush and vacuum cleaner to avoid cleaning to prevent any potential damage to the blade's teeth.

Blade Maintenance:

Check the condition of the blade regularly for any signs of damage, such as cracks or dullness. Replace the blade if necessary to ensure the saw's efficiency and cutting accuracy.

For band saw blades with teeth, consider toothed band saws, including MJ319A, MJ319B, and MJ319C, inspect the teeth regularly to monitor their sharpness and integrity. Sharpen or replace the blade with a saw with worn or damaged teeth.

Lubrication:

Apply lubricant to the moving parts of the band saw, such as bearings and guides, to ensure smooth operation and prevent wear.

Regular Inspections:

Inspect the band saw periodically to check for loose bolts, damaged parts, or any signs of abnormal wear.

Ensure proper alignment and tracking of the blade to prevent it from slipping off the wheels and reduce uneven blade wear.

Check the tension of the blade to ensure it is properly tightened to maintain stable and accurate cutting performance.

Follow Manufacturer's Guidelines:

Always follow the maintenance instructions and guidelines provided by the band saw manufacturer to ensure proper care and maintenance of the machine.

The uses of an MJ319 wood band saw are numerous, and it is a great addition to any woodworking shop.

Choosing an appropriate wood band saw helps stock holders meet clients' demands, optimize operational efficiency, and maximize profit margins. When selecting a band saw, consider the following three-in-one combo tips:

Application Suitability

Select a saw that will excellently handle the material type and thickness of the intended projects. Also, ensure the saw has features compatible with the project's cutting accuracy and complexity requirements. For instance, a saw with variable speed control will be suitable for cutting different materials, while one with a digital laser guide will enhance cutting precision.

Capacity and Specifications

Choose a saw with a cutting capacity that will handle the maximum sizes of project pieces. Also, pick one with motor power, blade size, and speed suitable for the project type. A large capacity saw with a high-power motor works well for cutting hardwood and thick stock.

Machine Quality and Safety

Opt for a saw with an automatic blade tensioning system, which maintains proper blade tension throughout the cutting process. Such a machine will ensure consistent cuts and reduce downtime for blade adjustments. Also, ensure the saw has essential safety features, like a blade guard, emergency stop button, and overload protection.

Q1: What type of blade does a band saw use?

A1: Band saws use loop blades that run on two wheels.

Q2: Which is better a band saw or a table saw?

A2: A band saw is better for cutting curves, while a table saw is ideal for making straight cuts. The two saws can complement each other in a workshop.

Q3: Can a band saw cut metal?

A3: Yes, there are metal-cutting band saws. They are different from wood band saws in that they have a thicker blade with a finer tooth pattern.

Q4: What are the common parts of a band saw?

A4: All band saws, regardless of type, have the following parts; blade, wheels, frame, guider, mangling device, table, trunnion, and column.