(2422 products available)

Lubricating tools are devices or instruments used to apply lubricants, such as oil or grease, to reduce friction and wear between moving parts in machinery and equipment. Here are some common types of lubricating tools:

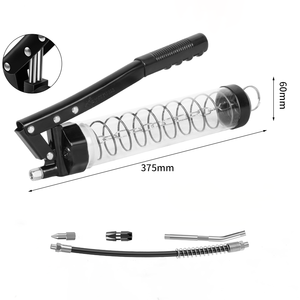

Lubrication Gun

A lubrication gun is a hand-operated or powered tool used to dispense lubricant, usually grease, into bearings and other fittings. It consists of a barrel that holds the lubricant, a nozzle or tip for reaching fittings, and a trigger or lever mechanism to control the flow. Lubrication guns ensure precise and controlled application of lubricant, reducing the risk of overfilling or contamination.

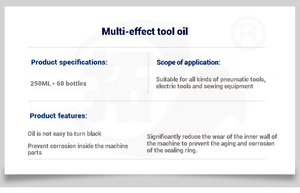

Oil Can

An oil can is a simple hand-held container used to dispense small amounts of oil for lubrication. It typically has a spout or nozzle that allows for precise application to moving parts. Oil cans are commonly used in tasks such as sewing machine maintenance, bicycle chain lubrication, and other applications where controlled oil application is required.

Grease Fitting

A grease fitting, also known as a greased nipple or lubrication fitting, is a small metal fitting installed on machinery and equipment. It allows for the easy injection of grease into internal components using a lubrication gun. Grease fittings are commonly used in applications such as automotive chassis, industrial machinery, and other systems requiring periodic greasing to reduce friction and wear.

Bearing Lubrication Tool

bearing lubrication tools are devices designed to facilitate the application of lubricant to bearings in order to ensure smooth operation and longevity. These tools can vary in design, from simple oil cans to more specialized equipment like automated lubrication systems. Bearing lubrication tools help prevent friction-related issues, reducing wear and tear on bearings and improving overall machinery performance.

Automatic Lubrication System

An automatic lubrication system is a device or system designed to deliver a continuous and controlled supply of lubricant to various components of machinery and equipment while in operation. These systems are designed to reduce friction and wear, thereby improving the performance and lifespan of critical parts, such as bearings, chains, and gears, by ensuring consistent lubrication. Automatic lubrication systems are widely used in industrial, automotive, and heavy machinery applications, where regular manual lubrication may be challenging or time-consuming.

Lubricating tools come in handy with specifications that are important for carrying out their functions. Here are some of the specifications:

Capacity

Each lubricating tool has its capacity specification that determines how much lubricant it can hold. For instance, a grease gun may hold 400 grams of grease, while a lubricant spray bottle may hold 500 ml of oil. The capacity affects the frequency of refill or lubricant application.

Pressure

Pressure is a specification that is applicable to tools like the grease gun. The pressure is measured in psi or bar, which indicates the force at which the grease is dispensed. A grease gun can have a pressure of 8000 psi, which dispenses grease at a very high force.

Nozzle Size

The nozzle size specification varies from one lubricating tool to the other. Each nozzle comes with a different size and design adapted for different applications. For example, a grease gun may have a nozzle size of 4–6 mm, while an oil can may have a nozzle of 2 mm.

Material

Various lubricating tools are made from different materials. The material affects the durability and suitability of the tool for different applications. Common materials include stainless steel, aluminum, plastic, and brass. For instance, stainless steel is mostly used for nozzles and tips due to its corrosion resistance and durability.

Viscosity

Different lubricating tools are designed to accommodate different lubricant viscosity specifications. The viscosity affects the flow and the suitability of the tool for various applications. For example, lubricating oils may have different viscosity grades, such as 10W-30 or 20W-50, while greases may be thick or semi-fluid.

Application

Each tool is specifically designed for a specific use or application. For instance, a grease gun is used for applying grease to bearings and joints, while an oil can is used for applying oil to small moving parts. The design and nozzle type are also influenced by the application.

Maintaining lubricating tools is very important to ensure they are in good working condition. The following are some general maintenance practices of lubricating tools:

Choosing the right lubricating tool is an essential step in ensuring the tool meets the needs of a target audience. Here are some factors to consider when selecting a suitable lubricating tool.

Consider the type of machinery or equipment to be lubricated. Different tools are designed for specific purposes. Identifying the need will help choose the right tool. For example, a grease gun may be selected for high-viscosity lubricants like grease, while an oil can or sprayer may be chosen for low-viscosity lubricants like motor oil.

Think about the frequency and amount of lubricant application required. If regular lubrication is needed, a more efficient, faster tool like a pneumatic grease gun may be selected. For occasional use or small applications, a manual tool like a lubricating syringe may be sufficient.

When selecting a lubricating tool, consider the type of lubricant to be used. Different tools are designed for different types of lubricants. Ensure the tool is compatible with the lubricant being used. For example, if using grease, ensure the tool can handle and dispense grease properly.

Another factor to consider is the precision and control required during lubricant application. Some tools offer more precision and control than others. If precise and controlled lubricant application is necessary, choose a tool that allows for accurate dispensing and application of the lubricant. For example, a lubricating syringe offers precision and control, while a grease gun dispenses grease in bulk.

When selecting a lubricating tool, consider the maintenance and cleaning requirements of the tool. Some tools may require more frequent cleaning and maintenance than others. Choose a tool that is easy to clean and maintain to ensure optimal performance and longevity. Consider features like removable and washable parts, accessible openings for cleaning, and durable materials that can withstand regular cleaning.

It is also important to consider the budget and cost-effectiveness of the selected tool. Evaluate the features, durability, and performance of the tools available within the desired price range. Sometimes, a higher-priced tool may offer long-term savings through durability and efficiency, reducing the need for frequent replacements or additional maintenance. Consider the overall value and cost-effectiveness of the tool chosen.

When selecting a lubricating tool, consider the ergonomics and comfort of the tool. Look for tools with comfortable grips, lightweight designs, and ergonomic features that minimize strain or fatigue during use. Ergonomic tools improve user comfort and efficiency, leading to better performance and productivity.

Furthermore, also consider the availability of lubricating tools and accessories. Ensure that the chosen tool's compatible lubricants and other necessary accessories are easily accessible. This ensures a smooth and hassle-free experience when using the tool.

For DIYers, using a lubricating tool is pretty straightforward. The steps are as follows:

Identify Lubrication Points

Firstly, the moving parts of machinery and equipment are recognized. Secondly, the users' manuals are referenced to confirm the lubrication points.

Select the Right Lubricant

The lubricant type is chosen based on the requirements of the lubrication points. For instance, the appropriate viscosity and properties are ensured if it's grease or oil.

Clean Lubrication Points

Before applying the lubricant, dirt and old lubricant residues are removed from the lubrication points. This cleaning helps prevent contamination and ensures the effectiveness of the new lubricant.

Fill the Lubricating Tool

The lubricating tool, like a grease gun or oil can, is filled with the selected lubricant. The right amount is ensured to prevent wastage and ensure precise application.

Apply the Lubricant

The lubricating tool is used to apply the lubricant to the identified lubrication points. The required amount is dispensed carefully into bearings, joints, and other moving parts.

Check and Clean Excess

After lubrication, excess lubricant is checked and cleaned from the surrounding areas. This helps maintain cleanliness and prevents the accumulation of dust and debris.

Inspect and Test

Once the lubrication is done, the machinery or equipment is inspected and tested to ensure proper function. Any unusual noise or issue is promptly addressed.

Q1: How often should I lubricate my tools?

A1: The frequency of tool lubrication depends on the tool's usage. Tools used frequently require lubrication every few weeks or after every use. Tools with infrequent use need lubrication before use or after a long period of storage.

Q2: What is the right way to lubricate tools?

A2: There is no right way to lubricate tools, but there is a right tool for every way. Users can use spray lubricants, oils, or greases to apply a thin layer of lubricant on tool surfaces. They should ensure excess lubricant is wiped off to prevent dirt attraction.

Q3: What is the importance of tool lubrication?

A3: Tool lubrication reduces friction and prevents wear and tear, thus prolonging the lifespan of the tools. It also prevents the tools from jamming, saving users time and energy.