(1508 products available)

Types of low pressure PU foam machines

A low pressure PU foam machine makes polyurethane foam by mixing two components: isocyanate and polyol. In contrast to high pressure machines, which use a hydraulic pump to force the liquid through a mixture head, low pressure machines use a gear pump to move the liquid at low pressure. This means that they can create specific formulations of foam, like soft foam, rigid foam, and memory foam, for different applications such as mattresses and cushion manufacturing.

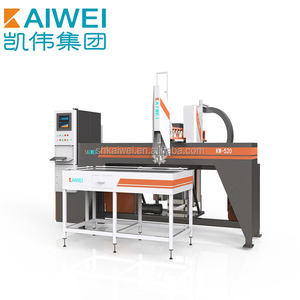

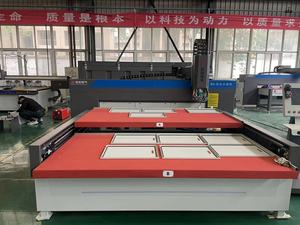

Generally speaking, there are two types of low pressure PU foam machines: the fixed type and the movable type. Both types of machines are compatible with polyols and isocyanates, and they can efficiently blend and dispense low pressure foams by using a precise metering system. However, they have different characteristics and applications.

The specifications for the low pressure PU foam injection machine differ based on the needs of the buyers. It varies according to the model or type of the machine. Here are some key specifications to know about these machines:

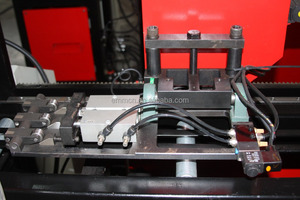

Mixing Head

Production and Cylinder Capacity

Pump

Users must understand that the maintenance of the PU foam machine is closely linked to the handling of the device. First things first, cleaning the mixing head is important for its sustenance. The maintenance task is pretty easy, and the machine has a self-cleaning function.

Secondly, use the right lubricants. The low-pressure foam machine functions seamlessly when it's free of friction. Low-friction surfaces require the application of suitable and recommended lubricants. Customers can check with the manufacturers for the best lubricants to use.

Some machines have automatic oil pumps. They ensure the oil goes to the needed parts in the mixing unit. It keeps the foam injection machine running smoothly and well-oiled.

Check the device frequently for wear and tear. Constant use may wear some parts of the foam machine. Get a skilled professional to assess the condition of the machines from time to time. Pay attention to the seals and gaskets, as they may need replacement after some time.

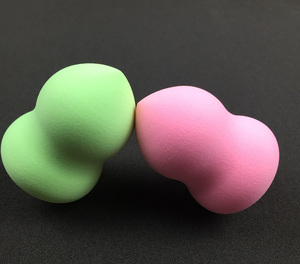

There are many applications for low-density polyurethane foam, which is produced using low pressure PU foam machines. Low pressure PU foam is soft, light, and elastic, making it comfortable. It has excellent thermal insulation, noise reduction, and cushioning properties. Here are some industries that use low pressure PU foam machines:

Furniture industry

Low-pressure PU foam is widely used in the furniture industry. It is applied as soft cushions in chairs, sofas, and benches to increase comfort. When used in bedding, low-pressure PU foam can provide a better night's sleep for consumers. Therefore, it is often used in making mattresses.

Packaging industry

In the packaging industry, low-pressure PU foam serves as a protective cushion for fragile or easy-to-break products, such as glass products and electronic items. Low-pressure PU foam achieves insulation and shockproof effects, ensuring that goods arrive in perfect condition.

Automotive industry

In the automotive industry, low-pressure polyurethane foam fills gaps and spaces in car interior assemblies. This alleviates impact, cuts down on noise, and makes for a ride that's easier on the ears. The upholstery of automobiles also includes low-pressure PU foam. It is frequently used in car seats, armchairs, and backrests to improve the comfort of riding.

Insulation industry

Low-pressure PU foam has great thermal insulation properties, so it is popular in the insulation industry. For instance, low-pressure PU foam is used as insulation in refrigerators, cold storage, and HVAC pipes.

Medical industry

The low-pressure PU foam provides a softer cushion in medical and healthcare areas. For instance, it can be used to make wheelchairs, beds, and other medical equipment and appliances. It can also be used in prosthetic devices and orthopedic products.

Construction industry

Low-density polyurethane foam achieves the effects of sealing and insulating through thermal contraction, making it widely used in the construction industry. It can be applied in the construction industry for thermal insulation, sealing of windows and doors, filling, and sound insulation.

Sports and entertainment industry

Low-pressure PU foam is used to make sports equipment like kneepads, elbow pads, and protective helmets. Meanwhile, it can be found in recreational places like theaters and concert halls. Low-pressure PU foam provides noise reduction and sound absorption, improving the acoustic environment.

Aerospace and automotive industries

Low-pressure PU foam is employed as lightweight materials in high-end industries like aerospace and automotive. For instance, it can be used in vehicle lightweighting, which requires heat insulation, sound insulation, and noise absorption. This is to meet the demands of automotive quality and safety standards.

When selecting a low pressure PU foam spraying machine, several important factors need to be carefully considered. One of the first things to take into account is the machine's maximum output capacity, which is generally expressed in kilograms per minute. In line with this, the buyer has to be sure of the amount of foam they intend to produce and select a machine with an applicable output capacity. Now, if one is producing a small amount of foam, a machine with a lower maximum output capacity is preferable. If one is looking to produce a large amount of foam at once, a machine with a higher output capacity is more ideal.

Secondly, buyers need to determine the kind of foam products they are going to be producing and select the machine that can handle the specific foam chemicals they settle on. As discussed earlier, there are different types of foam reactions, and the buyer should carefully choose a machine that will match their intended foam type.

It is also important to consider the pressure of the machine. Buyers should carefully determine their application needs and select a machine that has the ideal spray pressure. For example, if one seeks to produce low-density foam that will have light-fill applications, a low-pressure foam machine is more preferable. On the other hand, a high-pressure foam machine would be better suited for applications that require greater energy and pressure to produce high-density foams.

Additionally, buyers have to consider the level of automation.

Another important thing to consider is the maintenance requirements of the machine. Buyers should select a machine with low maintenance requirements, which will help reduce downtime and also ensure smooth operation.

Lastly, buyers should consider a machine's ergonomic design. Selecting a machine with an easy-to-use control system and a lightweight design will help operators work with the machine more quickly and comfortably.

Q1: How does a low-pressure PU foam machine work?

A1: The machine works by mixing two components, namely the isocyanate and polyol blend, with the help of a heating and chemical reaction between the two components forms polyurethane foam.

Q2: What are the advantages of using a low-pressure PU foam machine?

A2: The low-pressure foam machines benefit users by reducing waste, lower costs, improved quality control, and faster production.

Q3: In what industries are low-pressure PU foam machines used?

A3: Low-pressure PU foam machines are used in diverse industries ranging from manufacturing, construction, automotive, packaging, refrigeration, and furniture industries.

Q4: Can users customize the properties of the foam produced by low-pressure machines?

A4: Yes, users can customize the properties of the foam by selecting specific polyol blends, additives, and catalysts to achieve the desired characteristics.