(157 products available)

K31 MAN turbocharger is a turbocharger used in trucks and vehicles with high-performance engines. It is a popular choice for those looking to upgrade their engine performance, fuel efficiency, and emissions control. The K31 MAN turbocharger improves vehicle drivability, responsiveness, and overall performance. The K31 MAN turbocharger is suitable for various engine types, including the inline 6-cylinder 4-stroke water-cooled diesel engine. There are several types of K31 MAN turbochargers, including the turbo actuator, turbocharger housing, and turbo turbine wheel. The turbine wheel is further divided into standard turbine wheels and asymmetric turbine wheels. The turbine wheel drives the rotation of the turbine and is the most critical part of the K31 MAN turbocharger.

K31 MAN Turbo Actuator

The K31 MAN Turbo Actuator is responsible for controlling the turbocharger's boost pressure and optimizing engine performance. It does this by adjusting the position of the wastegate valve in response to signals from the engine control unit. By regulating exhaust flow through the turbocharger, the actuator ensures that the desired level of boost is maintained across various engine operating conditions. This precise control of boost pressure enables the engine to deliver consistent power and torque, enhancing overall vehicle performance and drivability.

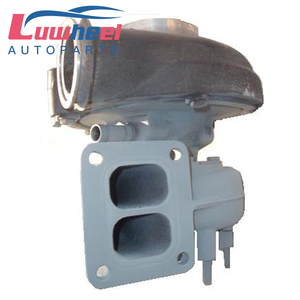

K31 MAN Turbocharger Housing

The K31 MAN turbocharger housing is a crucial component that surrounds the turbine and compressor wheels. It is divided into two main parts: the turbine housing and the compressor housing. The turbine housing collects exhaust gases from the engine and directs them onto the turbine wheel, causing it to spin. The design of the turbine housing affects the turbocharger's performance characteristics, such as response time and boost pressure. On the other hand, the compressor housing encases the compressor wheel and channels the intake air through the turbocharger. Together, these housings facilitate the efficient transfer of energy from exhaust gases to the intake air, boosting engine performance and efficiency.

K31 MAN Turbocharger turbine wheel

The turbine wheel is a vital component of the K31 MAN turbocharger, as it converts the energy of the flowing exhaust gases into rotational energy. The design and material of the turbine wheel directly impact the turbocharger's efficiency, response time, and overall performance. There are two main types of turbine wheels: standard and asymmetric. The standard turbine wheel features a traditional blade design that balances performance and manufacturing simplicity. In contrast, the asymmetric turbine wheel boasts an irregular blade arrangement that further enhances the K31 MAN turbocharger's efficiency and responsiveness, delivering more torque and power across a broader engine speed range.

1. Engine Size

The K31 MAN Turbo is a suitable turbocharger for engines with a displacement of up to 10.0 liters.

2. Compression Ratio

The K31 MAN Turbocharger has a compression ratio of 1:20, which contributes to its efficiency in compressing air into the engine's cylinders.

3. Maximum Power

The K31 MAN Turbo can generate a maximum power output of around 370 kW (500 hp). This power output makes the turbocharger suitable for heavy-duty trucks and other commercial vehicles.

4. Maximum Torque

The K31 turbocharger can produce a maximum torque of approximately 1,600 Nm (1,180 lb-ft) at engine speed of 1,100 to 1,500 rpm. This high torque output allows for better acceleration and pulling power, especially when carrying heavy loads.

5. Length and Height

K31 MAN Turbo has a length of 408 mm (16.1 in) and a height of 232 mm (9.1 in), making it a compact turbocharger for its class.

6. Weight

The K31 MAN Turbo has a weight of 20 kg (44 lbs), which is relatively light for a turbocharger of its size and power output.

7. Maximum Speed

The turbine wheel of the K31 MAN Turbo can spin at a maximum speed of 140,000 revolutions per minute (rpm), which is necessary for generating sufficient boost pressure.

8. Materials

The K31 MAN Turbocharger is constructed using high-quality materials, including aluminum for the compressor housing and cast iron for the turbine housing. These materials ensure durability and resistance to high temperatures and pressures.

1. Regular Oil Changes

The K31 MAN Turbo requires regular oil changes to keep the turbocharged properly lubricated. This generally means changing the oil every 7,500 miles or every six months, whichever comes first. Using high-quality oil that meets the MAN Turbo's specifications is also essential.

2. Air Filter Maintenance

Maintaining the air filter is crucial for the K31 MAN Turbo. A clean air filter guarantees a steady and unobstructed airflow to the turbo, optimizing its performance and longevity. Regularly inspecting the air filter and replacing it every 15,000 to 30,000 miles, or as needed, is essential. This prevents dust, dirt, and other contaminants from entering the engine and potentially damaging its components.

3. Cooling System Inspection

The K31 MAN Turbo relies on a well-functioning cooling system to regulate its temperature. Periodically inspecting the cooling system, including the coolant level, hoses, and thermostat, is essential. This ensures the turbo remains within its optimal temperature range. Maintaining the cooling system is critical to preventing overheating, which can cause severe damage to the turbo and other engine components.

4. Visual Inspection

Inspecting the turbocharger visually for any signs of damage, oil leaks, or excessive wear and tear is essential. If any issues are detected, addressing them immediately is crucial. This prevents minor problems from escalating into major ones, saving time and money on repairs.

5. Exhaust System Inspection

The exhaust system plays a crucial role in the turbocharger's function. Periodically inspecting the exhaust system, especially the exhaust pipes and the catalytic converter, is essential. This ensures unobstructed exhaust flow and maximizes the turbo's efficiency.

6. Professional Inspection and Cleaning

Having a qualified mechanic or technician inspect and clean the turbocharger regularly is essential. This ensures all components are in good condition and functioning optimally. The professionals have the right tools and expertise to perform a thorough inspection and cleaning, which is crucial for the turbocharger's performance and longevity.

Business buyers should consider the following factors when choosing a K31 MAN turbocharger:

Understanding Engine Requirements

When selecting a turbocharger, it's crucial to have a comprehensive understanding of the engine's needs. Factors such as engine size, type, and its intended use or application play a significant role. For instance, a larger engine may require a more robust turbocharger to efficiently compress the intake air, ensuring optimal performance. Similarly, understanding the fuel type utilized in the engine is important, as different fuel types may impact the turbocharger's performance and requirements. Moreover, considering the altitude at which the vehicle operates is essential as well. Higher altitudes present challenges to turbochargers, necessitating careful consideration of this factor when choosing the right one. By taking all these aspects into account, one can make an informed decision and select a turbocharger that perfectly aligns with the engine's requirements, resulting in enhanced performance and efficiency.

Researching the Right Turbocharger for the Vehicle

It is important to thoroughly investigate and identify the ideal turbocharger that seamlessly aligns with the vehicle. This entails considering the vehicle's make, model, and year of production, as well as its engine specifications and performance characteristics. One should also take into account the desired performance objectives, such as increased horsepower or torque, as well as the intended usage of the vehicle, whether it's for daily commuting, towing, or high-performance racing. With this comprehensive understanding, one can confidently select a turbocharger that optimizes the vehicle's performance, ensuring a smooth and efficient driving experience tailored to specific needs and preferences.

Consulting Professionals or Experienced Users

Consulting professionals or experienced users can be extremely helpful when selecting a turbocharger. Professionals, such as mechanics or performance specialists, possess extensive knowledge and expertise in turbocharger selection. They can provide valuable insights and recommendations based on their experience working with various vehicles and turbocharger models. Similarly, experienced users who have successfully installed and utilized turbochargers in their vehicles can share their firsthand experiences and lessons learned. Their practical knowledge can guide one away from potential pitfalls and towards the most suitable turbocharger for a specific vehicle.

Evaluating Quality and Reliability

When choosing a turbocharger, it's crucial to assess its quality and dependability. Selecting a turbocharger manufactured by a reputable and trusted brand is essential, as these companies are recognized for their commitment to excellence and precision engineering. Such turbochargers are crafted with meticulous attention to detail, utilizing superior materials and components, resulting in enhanced performance and durability. Furthermore, reading reviews and testimonials from other users can offer valuable insights into the turbocharger's performance and reliability. This feedback can assist one in making an informed decision and selecting a turbocharger that meets specific needs and expectations, ensuring optimal performance and longevity.

Consider Future Maintenance and Support

When selecting a turbocharger, it's essential to consider future maintenance and support aspects. Opting for a turbocharger that is easily installable and maintained is crucial, as this can significantly simplify upkeep and potential repairs. Furthermore, selecting a turbocharger with readily available replacement parts can save time and money in the long run. This ensures that, in case of wear or damage, finding compatible components is hassle-free, minimizing downtime and maintaining optimal performance. Additionally, choosing a turbocharger backed by reliable customer support can be advantageous. This provides peace of mind, knowing that assistance and guidance are accessible if needed. By considering these factors, one can make a well-informed decision and select a turbocharger that aligns with long-term needs and convenience.

Replacing a K31 turbo is a technical process that requires attention to detail. The following are the steps to take when replacing the K31 turbocharger.

Disconnect the Battery

To start with, the battery needs to be disconnected. This is done to avoid any electrical connections from interfering with the installation process. The battery's negative terminal should be unfastened before anything else.

Remove the Old Turbocharger

Removing the old turbocharger entails loosening the clamps and bolts that hold it in place and disconnecting the pipes and fittings attached to it. The oil feed and return lines, as well as the exhaust downpipe, must be disconnected. The turbo bolts may need to be removed after the manifold nuts have been loosened to allow for more mobility and access.

Prepare the New Turbocharger

Before the new K31 turbo is installed, it must first be prepared. This preparation includes making sure that all the essential pipes and fittings have been attached, as well as the oil feed lines and return lines and the intercooler and intake pipes.

Install the New Turbocharger

The new turbo should be positioned in the same manner as the previous one. After that, the exhaust manifold should be bolted down, and the oil feed and return lines should be connected to the turbo. Additionally, it is essential to ensure that the intake pipes and intercooler parts are correctly positioned.

Reconnect the Electrical Connections

Electrical connections are reconnected as soon as the new turbo is installed. This includes any sensors or actuators connected to the turbo. It is important to ensure that all electrical connections are appropriately connected to avoid any problems with the turbo's performance.

Check and double

Once everything is connected, the technician will go over the entire process and ensure that every component is installed properly and securely. This includes checking all hoses, pipes, and electrical connections to ensure everything is in good working order.

Refill Engine Oil and Coolant

once the new turbo has been installed and all connections have been made, the engine oil and coolant levels should be checked and topped up as needed. This is important to maintain proper engine performance and prevent overheating.

Reconnect the Battery

After everything has been checked and double-checked, the battery should be reconnected. This is done by reconnecting the negative terminal and ensuring all connections are secure.

Start the Engine and Test Drive

The final step is starting the engine and taking a test drive. This is important to ensure that everything is working properly and that there are no issues with the new turbo's performance.

Q1: How can users know a turbocharger is faulty?

A1: A faulty turbocharger will have clear symptoms. The engine will be lacking power, and there will be a hissing or whining noise coming from the turbo. Users may also see exhaust smoke, especially if the smoke is gray. There may be a check engine light on, and the car's fuel consumption may increase. If the air filter is clean and there is no obstruction, users should have the turbo checked.

Q2: Can users repair turbochargers?

A2: Turbochargers can be repaired, but this is only advisable when the K31 turbocharger is repairable by a trained technician. Repaired turbochargers can be as good as new, but the repair process is usually long and expensive. In most cases, replacing the turbo with a new unit is more economical.

Q3: How long does a turbo replacement last?

A3: A new turbo replacement can last over 100,000 miles. However, the longevity of the turbo depends on various factors, such as driving conditions, driving habits, and oil changes. Users should ensure proper maintenance to get the most out of the turbo.

Q4: Does a turbocharged engine require special maintenance?

A4: Turbocharged engines do not need different maintenance schedules from non-turbocharged engines. However, because turbos use exhaust to spin a turbine and force more air into the engine, proper care of the exhaust system is critical. Ensuring that the exhaust system stays healthy will keep the turbo functioning properly.