Understanding Inject Pipe: An Essential in Fluid Dynamics

The inject pipe is a critical component utilized in various industries, specifically designed for the efficient transport of liquids and gases. Often found in hydraulic systems, oil pipelines, and chemical processing, inject pipes facilitate the safe and controlled movement of materials. The robust design and reliable performance of inject pipes make them indispensable for maintaining operational efficiency across multiple applications.

Types of Inject Pipes: Varieties to Suit Different Needs

Inject pipes come in several types, each tailored to specific applications and materials. Understanding these varieties can aid in selecting the right inject pipe for the task at hand:

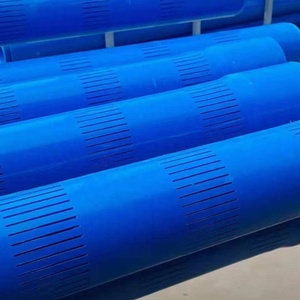

- Rigid Inject Pipes: These are typically made from strong materials like steel or PVC, offering excellent durability and strength for high-pressure applications.

- Flexible Inject Pipes: Constructed from rubber or flexible plastics, these pipes provide versatility, enabling easier installation in tight spaces and reducing the risk of breakage.

- Insulated Inject Pipes: Designed to withstand extreme temperatures, these pipes are lined with insulating materials to maintain the desired temperature of the fluids being transported.

- Corrosion-Resistant Inject Pipes: Often treated with special coatings or materials like stainless steel, these pipes are ideal for harsh chemical environments, ensuring longevity and reliability.

Applications of Inject Pipes: Where Function Meets Demand

Inject pipes are employed across a multitude of industries due to their functional versatility. Here are some of the common applications where inject pipes play a vital role:

- Oil and Gas Industry: Used for the transport of crude oil, natural gas, and other by-products, inject pipes are essential for efficient extraction and distribution.

- Chemical Processing: They facilitate the movement of reactive chemicals in factories, ensuring safe and controlled environments for chemical reactions.

- Agriculture: Inject pipes are utilized in irrigation systems, delivering water and nutrients directly to the roots of crops.

- Construction: Used in HVAC systems (heating, ventilation, and air conditioning), inject pipes transport fluids necessary for temperature control.

Key Features and Advantages of Inject Pipes: Why They Matter

Inject pipes possess unique features that contribute to their effectiveness in fluid transport. Understanding these benefits can help businesses make informed decisions:

- Durability: Built from robust materials, inject pipes are designed to withstand challenging conditions, ensuring long service life and reducing maintenance costs.

- Efficiency: With streamlined designs, inject pipes minimize resistance and allow for higher flow rates, improving overall efficiency in fluid transfer.

- Versatility: Available in various sizes and materials, inject pipes can be customized to suit a wide range of applications, making them a flexible solution for businesses.

- Safety Features: Many inject pipes come equipped with safety mechanisms to prevent over-pressurization and leaks, ensuring workplace safety for operators.