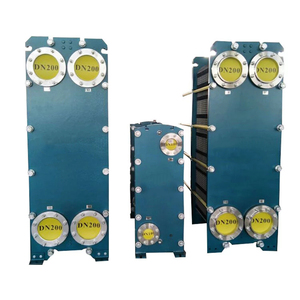

(61 products available)

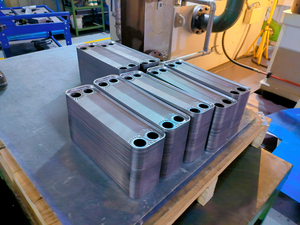

The GEA VT10 plate heat exchanger, part of the GEA Varitex series, is an innovative unit in the large plate heat exchanger family. All GEA Varitex heat exchangers are designed using a unique modular design principle. They have more than 10,000 different combinations of plates and frames and can be structured with various materials, allowing for excellent flexibility and service.

Stainless Steel:

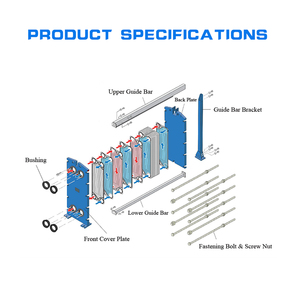

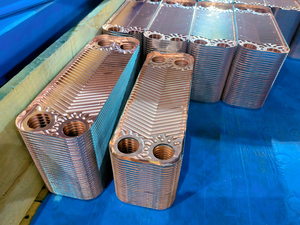

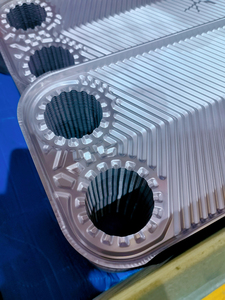

The carrier plates and bolts are made of stainless steel, which is known for its tensile strength and resistance to rust and oxidation. The heat transfer plates' top and bottom bars also feature reinforced engineering plastics to protect the plates while supporting the plastic bars. Stainless steel plates provide excellent corrosion resistance, allowing them to be cleaned thoroughly without degrading or damaging the unit.

Aluminum Bronze:

A mixture of brass and aluminum that produces a round alloy. It has anti-corrosion properties, and both alloys work together to assist in corrosion resistance.

Floating head heat exchangers:

A heat exchanger design permits changes in spacing between the tubes and the tube sheet as well as differential expansion between the tube bundle and the shell. In service, this design reduces tube bundle distortion caused by thermal expansion and facilitates the unfouling of tubes mechanically.

Barrel Heat Exchangers:

A barrel heat exchanger has a cylindrical barrel that houses the heat exchange elements or tubes. A system for circulating the working media is included, consisting of inlet and outlet headers or tanks located at the barrel's ends. It is a water-to-water system in which water that serves as heating media is pumped through a barrel heat exchanger that raises the water temperature.

Folded Plate Heat Exchangers:

Energy recovery equipment known as plate heat exchangers transfers thermal energy between two moving fluids. One of their main purposes is to recover waste heat from coolant fluids and transfer it back to process streams to reduce energy losses and enhance system efficiency.

The proper maintenance of the plate heat exchanger is crucial for maintaining efficiency, prolonging lifespan, and preventing costly breakdowns. Regular inspections should be scheduled to monitor the condition of the plates and gaskets. Look for signs of wear, damage, or leaks. Replace any damaged components promptly to avoid further issues. Clean the heat exchanger regularly to prevent the buildup of deposits that can hinder performance. The cleaning method will depend on the type of plate heat exchanger and the nature of the deposits. Ensure that the equipment is properly aligned and tightly bolted to prevent leakage and deformation. Monitor the operating parameters, such as temperature and pressure, to detect any anomalies that may indicate potential problems. Develop a maintenance log to record inspections, cleanings, and repairs for future reference. In some cases, it may be necessary to engage professional service providers for plate heat exchanger maintenance to ensure optimal results and compliance with industry standards. Following these maintenance tips can help keep the plate heat exchanger in good condition and maximize its efficiency and reliability.

Food and beverage processing plants

GEA VT10 plate heat exchangers are frequently used in food and beverage Processing plants for applications like milk pasteurization, juice and beverage cooling, and enzymatic inactivation, among others. They help to efficiently control the temperature of food products to guarantee safety and compliance with regulations.

Thermal energy recovery systems

Thermal energy recovery systems aim to recover as much residual thermal energy as possible from industrial processes. Such features can help save costs and reduce the environmental impact. Heat exchangers are the core of recovery systems; they play a key role in transferring heat from waste streams to other parts of the process for utilization.

Biotechnology and pharmaceutical industries

In the pharmaceutical and biotechnology fields, GEA VT10 plate heat exchangers are used for temperature control, sterilization, and cooling of biological products and pharmaceutical solutions. Sanitary design, precise temperature control, and efficient heat transfer functions of these devices can help ensure product integrity and compliance with industry standards.

Marine and offshore platforms

Marine and offshore platform industries need to efficiently transfer heat under harsh environmental conditions, such as oil and gas extraction, seawater desalination, and air conditioning systems, etc. GEA VT10 plate heat exchangers have good corrosion resistance and durability, which can meet the reliability and safety requirements of these industries.

When purchasing a heat exchanger, different factors need to be considered to choose the right heat exchanger.t

Fluid Properties

The properties of the fluid are the primary things to consider; the fluids' physical and chemical characteristics will help determine the right heat exchanger. Such characteristics include fluid composition temperature and pressure viscosity specific heat transfer corrosion and toxicity.

Heat Transfer Requirements

This includes heat transfer area needed and overall heat transfer coefficient. The amount of heat needed to be transferred and the temperatures of the fluids coming from and going to will also determine the size and configuration of the heat exchanger.

System Design

The design of the system where the heat exchanger will be integrated is an important factor to consider. Pressure drop constraints, available space, and configuration need to be considered when choosing a heat exchanger.

Operating Conditions

Operating conditions such as temperature and pressure must also be considered. The heat exchanger should be able to function in high-temperate situations without getting damaged or losing performance.

Q1: How can GEA plate heat exchangers be in the service for users?

A1: The GEA heat exchanger makes the plates' tensile strength and crystallization quality up to standard KTA 13/5 (tensile strength: more than 60,000, and crystallization quality: more than 5). In addition, every plate is put through an air-water test to check for invisible leakage before being assembled into a heat exchanger. This procedure guarantees leak-proof plate heat exchangers and enhances service life.

Q2: How many plate shapes does GEA have?

A2: The GEA plate shapes include the following: corrugated plates with different chevron angles, double-corrugated plates, and parallel flow plates. Meanwhile, a large number of plates with different gap dimensions are also available for choice.

Q3: What are some advantages of the GEA plate heat exchanger?

A3: GEA plate heat exchangers offer several benefits, including compact design, energy-efficient operation, and versatile applications.