(34 products available)

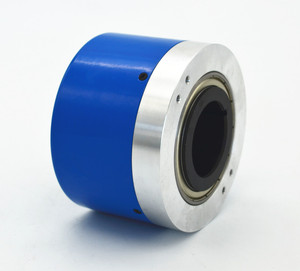

Fujitec supplies several kinds of encoders. They include:

Absolute Encoders

Absolute encoders from Fujitec are built to give a unique data signal over an encoder shaft's rotation. This implies that an encoder's position can be tracked even after an abrupt power loss. Such feature makes them ideal for several applications necessitating accuracy and reliability.

Incremental Encoders

Incremental encoders simply provide position feedback by measuring parts in motion indexes. Commonly, such encoders are used in velocity and position feedback systems. They are also frequently picked because of their simplicity and effectiveness in motion control tasks.

Rotaty Encoders

Rotary encoders assist in measuring shaft rotational motion. In industrial settings, Fujitec's rotary encoders are used in motors, robotics, and other machinery. Normally, they provide real-time positional data and hold up operational efficiency.

Linear Encoders

Linear encoders have the capacity to measure linear motion rather than rotational motion. They allow position tracking by moving along a straight line. In application, linear encoders are widely applied in CNC machines and printing devices. It is in these devices that accuracy is very critical.

Wire Encoders

Wire encoders, which are also referred to as cable displacement transducers, measure the motion of a retracted or extended cable. They are ideal for applications that involve tracking the position and movement of heavy loads and equipment. Moreover, these encoders are heavily utilized in dynamic and crane systems.

Fujitec encoders are widely utilized across industries. In the process, several industries benefit from operational efficiency enhancement and precision.

Automation and Robotics

Fujitec encoders have been popularly applied in automation and robotics. They are due to their precise motion control capability. Their rotary encoders assist robotic arms in accurately knowing their positions during operations. This leads to enhanced accuracy in tasks such as pick-and-place, assembling and welding, and a reduction in functional cycle times.

Manufacturing

In manufacturing, encoders are heavily used to provide positional feedback for various machines. Normally, Fujitec's linear and rotary encoders drive CNC and milling machines. They enhance the accuracy of cutting and shaping materials. Additionally, using encoders in industrial applications improves the mechanism's speed and efficiency. Also, they reduce the possibility of errors, which eventually impacts the production output positively.

Elevator Systems

Commonly, Fujitec is well known for its elevator manufacturing expertise. They use encoders in the elevator systems to have the position and speed control of the cab and doors. This ensures smooth operation. The application of encoders also enhances safety. They ensure the timeliness of operation and coordination with other systems such as fire alarms and building management.

HVAC Systems

HVAC systems incorporate encoders to drive dampers, fans, and compressors. This regulation of airflow and pressure enables desired indoor comfort levels. In addition, using encoders enables variable speed control. It reduces energy consumption by adjusting system operation according to the needs. This makes HVAC systems more efficient and effective.

Medical Equipment

Medical equipment has to be very accurate and, hence, rely on Fujitec encoders. These encoders are applied in imaging devices such as MRI and CT scanners. In these devices, they ensure accurate positioning during scanning. In surgical robots, the encoders help with precise movements during delicate surgeries. This has resulted in reduced patient recovery time and better health outcomes.

Although features rudely and specifications differ from model to model, they have some common features and specifications.

Business owners should consider some factors to purchase high-quality products. The factors include:

Material

Being one of the most essential components, the material used to cover the encoder affects its durability. A good Fujitec elevator encoder will have strong material that serves its purpose. In addition, such materials will be strong enough to bear extreme heat and cool temperatures.

Functionality

At this stage, it is recommended that business owners consider encoders' functionality. In this case, they have to specify what the encoders will be used for. Business owners will, for instance, look for wire encoders for a client who needs to track linear motion. They will also settle for rotary encoders for clients who need rotational motion. Even so, there are absolute and incremental encoders. Clients who need position stability will go for absolute encoders. Those who need continuous rotation will prefer incremental encoders.

Service

Apart from the product itself, the encoder's purchase experience is highly influenced by the surrounding service. Therefore, it is necessary to settle for a supplier who honors their client and guarantees them timely and effective services. Suppliers should also award their encoder maintenance guides to managers.

Avoid popular brands

Business owners should not necessarily settle for popular brands such as Fujitec encoderings. Instead, they should prioritize the brand that produces quality encoders. So, if a less popular brand produces quality products, there will also be a quality chance that these products will serve their purpose just as well.

Indeed, they bear strong and durable materials. Fujitec bearings are manufactured from premium-quality stainless steel. They, therefore, are capable of bearing harsh temperatures and extreme environmental conditions.

Fujitec encoders can reduce electricity bills. They contain energy-efficient components and work on electric motors, which do not consume a lot of electricity when running. In addition, they help control the function of electric motors and analyzers. This leads to a reduction in electricity-snatching motor overloads.

To purchase quality products, business owners should consider the material, maintenance required, functionality, and reviews of the encoder.

The average lifespan of fujitec encoders has been noted to vary between 7 and 15 years. However, the encoder longevity highly depends on the usage and environmental factors.