(88 products available)

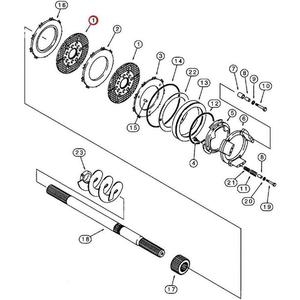

The friction disc and plate 237021A1 are used as a replacement part for different vehicles. The friction plate has different types that are suitable for use in various vehicles. The types of friction plates are as follows:

These are some general specifications for the friction disc and plate 237021a1:

Quality:

Using high-quality friction plates will improve vehicle performance. Friction plates made of high-quality materials can withstand wear and tear. They are durable.

Compatibility:

Friction discs and plates are made for different vehicles. When purchasing a friction disc and plate, ensure it is compatible with the vehicle. It should fit properly.

Size:

The size of the friction disc and plate depends on the vehicle's size and engine power. Larger vehicles and those with powerful engines require larger friction discs and plates. Ensure the size of the friction disc and plate being purchased is suitable for the vehicle.

Surface Finish:

The surface finish of the friction disc and plate affects its performance. A good surface finish improves grip and reduces noise. The plates and discs should have a smooth finish.

Material:

Friction discs and plates are typically made from steel. The friction disc and plate 237021a1 are made from durable material. They are steel. This steel is alloyed with other materials to improve its properties.

Heat Treatment:

The friction disc and plate 237021a1 undergo heat treatment. This process improves their strength and durability. The heat treatment process involves heating the steel to a high temperature. Then it is cooled rapidly.

Wear Resistance:

The friction plates and discs should have high wear resistance. This property ensures they last long and can withstand constant rubbing.

Friction Coefficient:

The friction coefficient of the plates and discs should be high. It should be between 0.4 and 0.6. This property ensures they provide a good grip.

Noise Level:

The friction plates and discs should not be noisy. If they are noisy, it could be a sign of damage.

Certification:

The friction plates and discs should be certified. They should meet international standards for quality and safety.

Maintaining the friction plates and discs extends their lifespan and improves their performance. Below are the maintenance practices:

Inspection:

Regularly inspect the friction plates and discs for signs of wear, damage, or cracking.

Check for Noise:

Listen for noise when the vehicle is in motion. Noise is an indication that the plates or discs are damaged.

Check for Vibration:

Feel for vibrations on the vehicle's pedals. The friction plates and discs are faulty if there is vibration.

Check for Slipping:

Slipping occurs when the vehicle's engine revs up without increasing the speed. This happens when the friction plates and discs are worn out.

Check for Overheating:

The vehicle's wheels will feel hot if the plates and discs are overheated. This is because the plates and discs are constantly rubbing.

Replace Worn Out Parts:

If any part of the friction discs and plates is worn out or damaged, replace them immediately.

Proper Adjustment:

Ensure the friction plates and clutch is properly adjusted. This prevents slipping and wear out.

Use Quality Oil:

Use high-quality oil for lubrication. The oil should be recommended by the manufacturer.

Cleanliness:

Keep the friction plates and discs clean. Remove any dust, dirt, or debris from them. Dust and dirt can cause wear and tear.

Avoid Overloading:

Do not overload the vehicle. Overloading puts too much pressure on the friction plates and discs.

Choosing the right 237021A1 friction disc and plate for a specific application requires a thorough understanding of the needs and conditions involved. Here are some key factors to consider:

Application:

Identify the specific use of the vehicle or machinery. Is it heavy-duty trucks for transporting heavy loads, racing cars for high-speed performance, or construction equipment operating in tough conditions? Different applications have different friction disc and plate requirements.

Load Capacity:

Consider the maximum load or weight that will be applied to the friction disc and plate. It should be able to handle the load without premature wear or failure. For heavy-duty applications, opt for friction discs and plates with high load capacity and stress tolerance.

Material Composition:

The material of the friction disc and plate surface can greatly affect performance and durability. For high-performance vehicles, consider friction discs and plates with advanced materials like carbon composites or ceramic-matrix composites. For heavy-duty or off-road applications, friction discs and plates made from durable metals or alloys may be more suitable.

Environmental Conditions:

Take into account the operating environment. Will the vehicle or equipment be exposed to extreme temperatures, moisture, dust, or corrosive substances? Choose friction discs and plates designed to withstand the environmental challenges and provide consistent performance in all conditions.

Performance Characteristics:

Determine the desired performance characteristics such as braking efficiency, noise level, vibration resistance, and thermal stability. Select friction discs and plates that align with the required performance standards and match the expectations of the application.

Compatibility:

Ensure that the chosen friction disc and plate are compatible with the existing flywheel, pressure plate, and clutch release system. Check the specifications, dimensions, and connection methods to ensure a proper fit and reliable operation.

Brand Reputation and Quality:

Consider the brand reputation and product quality of the friction disc and plate suppliers. Look for trusted brands known for their reliability, durability, and excellent performance. Read reviews, seek recommendations, and compare options to make an informed choice.

Cost:

While cost should not be the sole determining factor, consider the budget and find a balance between quality, performance, and affordability. Remember that investing in a high-quality friction disc and plates can lead to long-term savings through improved performance and durability.

By carefully evaluating these factors and conducting thorough research, one can choose the right friction disc and plate 237021A1 for their specific needs. It is also advisable to consult with professionals or experts in the field for further guidance and recommendations.

Friction disc and plates are an important part of the vehicle transmission system. It is important to have the right tools before attempting to replace a friction disc and plate 237021a1.

Below are the tools that will be needed:

Steps to replace Friction disc and plate 237021a1:

Q1. How should I know whether to resurface or replace my friction plates?

A1. As a general rule, if a friction disc and plate 237021a1 have been worn out beyond a particular limit, it is better to replace them. However, if the wear is not too extensive, they can be resurfaced. Mechanics usually check the damage level and the cost-effectiveness of each option before deciding.

Q2. What is the best material for friction plates?

A2. Friction plates can be made from various materials, including steel, copper, aluminum, and composites. The best material depends on the application. For high-performance vehicles, carbon-carbon or ceramic materials may be best due to their ability to withstand high temperatures. However, steel and composites are suitable for everyday use because they offer a good balance of cost, durability, and performance.

Q3. How can I tell if my friction disc and plate 237021a1 are worn out?

A3. Signs of wear include difficulty in gear shifting, grinding noises during gear shifting, and vibrations during gear shifting. Visual inspection can also help, although a professional mechanic's opinion is more reliable.

Q4. Can I use a friction disc and plate 237021a1 from another vehicle model?

A4. Using a friction disc and plate 237021a1 from another vehicle model is not advisable. They may not fit properly, leading to damage and costly repairs. Always use parts specified by the manufacturer.

Q5. How long do friction plates last?

A5. Friction plates can last between 30,000 and 70,000 miles, depending on driving habits, vehicle type, and maintenance practices. Stop-and-go traffic, heavy loads, and aggressive driving can shorten their lifespan.