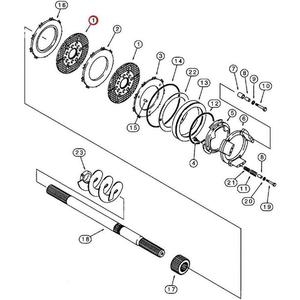

Understanding Forklift Friction Discs

Forklift friction discs are essential components that facilitate smooth operation and effective control within various forklift systems. Acting as a vital aspect of the transmission mechanism, these discs ensure the proper transfer of power from the engine to the wheels. Without high-quality friction discs, forklifts would struggle to function optimally, leading to inefficiencies and potential safety hazards.

Types of Forklift Friction Discs

There are several types of forklift friction discs, each designed to meet specific operational needs and standards:

- Alloy Friction Discs: Made from a combination of metals, these discs offer superior heat resistance and durability, ideal for heavy-duty applications.

- Composite Friction Discs: These lightweight discs usually incorporate non-asbestos materials, providing effective friction performance while reducing environmental impact.

- Rubber Friction Discs: Designed mainly for lighter applications, these discs provide excellent grip and are suitable for indoor use, where lower weight and less aggressive performance are required.

- Carbon Fiber Friction Discs: Known for their high-performance capabilities, carbon fiber discs are used in specialized forklifts where maximum heat resistance and durability are essential.

Applications of Forklift Friction Discs

Forklift friction discs are utilized in various scenarios where forklifts operate, particularly in industries that require rigorous handling of materials:

- Warehousing: Essential for controlling the movement of heavy loads in large warehouses, friction discs ensure forklifts function accurately and efficiently.

- Construction Sites: These discs enable forklifts to navigate challenging terrains, pivoting with precision while lifting and transporting heavy materials.

- Manufacturing: In manufacturing facilities, forklift friction discs support the fast-paced movement of materials and products, contributing to streamlined production lines.

- Logistics and Supply Chain: They play a crucial role in logistics operations, where speed and reliability in material handling are paramount.

Advantages of High-Quality Forklift Friction Discs

Investing in high-quality forklift friction discs comes with numerous benefits that enhance the overall performance and safety of forklift operations:

- Improved Safety: Reliable friction discs reduce the risk of slippage and braking issues, ensuring safe operation even in demanding conditions.

- Enhanced Durability: Quality materials ensure longevity and resilience, resulting in lower replacement costs and reduced downtime.

- Optimal Performance: High-quality friction discs ensure maximum efficiency in power transfer, contributing to better fuel efficiency and performance.

- Environmental Compliance: Many modern friction discs are designed to meet strict environmental regulations, reducing harmful emissions and promoting sustainability.