Introduction to Elastomeric Bearings for Bridge Applications

Elastomeric bearings for bridges are essential components designed to manage load transfer, accommodate movements, and prevent structural damage due to environmental stresses. These innovative bearings are made from high-performance elastomeric materials that offer exceptional resilience and durability, ensuring that bridges can withstand dynamic forces such as traffic loads, thermal expansion, and seismic activity. Their ability to absorb vibrations and provide flexibility is crucial for maintaining bridge integrity and longevity.

Types of Elastomeric Bearings for Bridge Structures

Elastomeric bearings are available in several types, each offering unique benefits tailored to different bridge designs and requirements. Understanding these types can help in selecting the most appropriate solution for your specific bridge project.

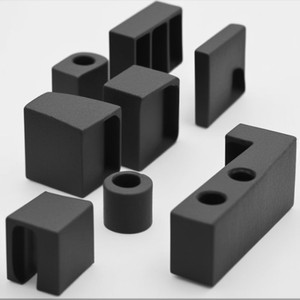

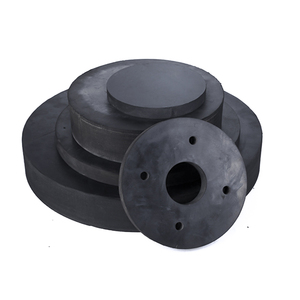

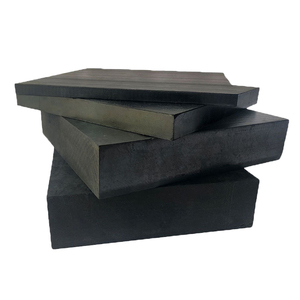

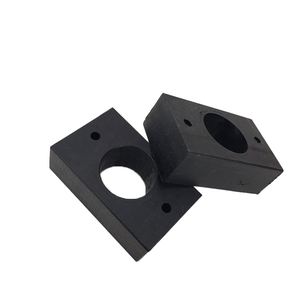

- Plain Elastomeric Bearings: Simple, cost-effective options consisting of a single layer of elastomeric material. Ideal for bridges with low movement demands.

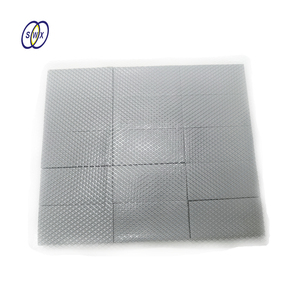

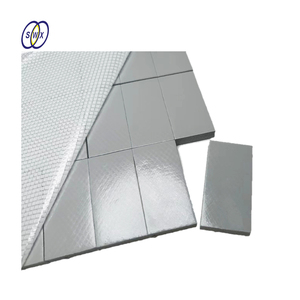

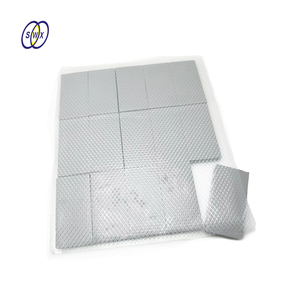

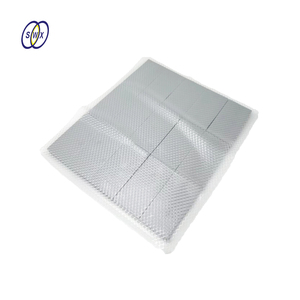

- Steel Laminated Bearings: Comprising alternating layers of elastomer and steel plates, these bearings provide increased load capacity and enhanced stability for larger structures.

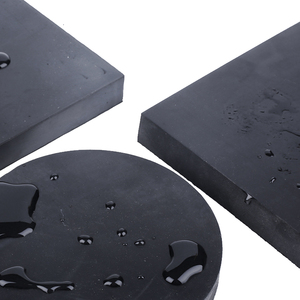

- Neoprene Bearings: Utilized for their weather-resistant properties, neoprene bearings excel in humid and coastal environments, protecting bridges from environmental wear and tear.

- Sliding Bearings: Featuring a low-friction sliding surface, these bearings are beneficial where horizontal movement is anticipated, such as in areas prone to seismic activity.

Features and Functions of Elastomeric Bearings for Bridges

Elastomeric bearings offer a range of features and functions that enhance their performance in bridge constructions:

- Load Distribution: Designed to effectively distribute loads over a large surface area, minimizing stress on the bridge components.

- Vibration Damping: The elastic properties of these bearings absorb vibrations from vehicular traffic, thus prolonging the life of the bridge structure.

- Movement Accommodation: elastomeric bearings can accommodate lateral, vertical, and rotational movements, ensuring the bridge can flex without sustaining damage.

- Durability and Longevity: Made of advanced elastomer materials, these bearings are resistant to weather, chemicals and aging, ensuring long-lasting performance.

Applications of Elastomeric Bearings for Bridge Engineering

The versatility of elastomeric bearings makes them suitable for various applications in bridge engineering, contributing significantly to both new constructions and maintenance of existing structures:

- New Bridge Constructions: Integral components in the design of modern bridges, providing essential flexibility and load management.

- Bridge Rehabilitation: Replacement of old bearings with elastomeric solutions can enhance the performance and safety of aging bridges.

- Seismic Retrofits: Increasingly used in seismic retrofit projects to improve the resilience of bridges in earthquake-prone areas.

- Highway Overpasses: Preferred for their ability to accommodate heavy traffic loads and dynamic forces.