(37602 products available)

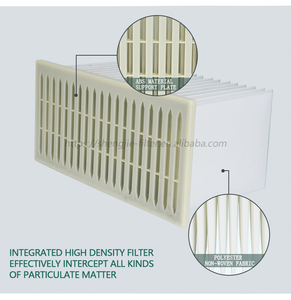

The dust filter bag is a crucial component in baghouse systems used for industrial dust collection. These bags are designed to efficiently capture dust particles, ensuring clean air emissions and a healthy working environment. Dust collector bags come in various materials such as polyester, acrylic, aramid, and fiberglass, each offering specific filtration efficiencies and temperature resistance.

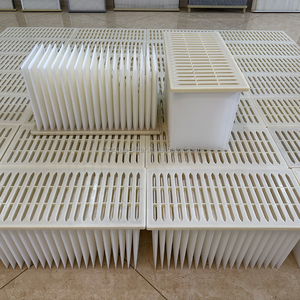

There are different types of dust bags for dust collector systems, including shaker, reverse air, pulse jet, and envelope designs. Shaker bags use mechanical agitation to remove dust, while reverse air bags employ a separate compartment for cleaning. Pulse jet bags utilize bursts of compressed air for cleaning, and envelope bags have a unique shape for efficient filtration.

When selecting dust collector filter bags, it is essential to consider factors such as filtration efficiency, air-to-cloth ratio, operating temperature, and chemical compatibility. These bags typically have a filtration efficiency ranging from 99% to 99.9% and can withstand temperatures up to 500°F. The filter bag dust collector should be selected based on the specific requirements of the application.

Baghouse dust filter bags offer features such as high dust-holding capacity, excellent airflow, and durability. The construction of these bags ensures minimal dust leakage and long service life. Additionally, advanced coatings can enhance the performance of dust bags for dust collector systems, making them suitable for various industries.

The use of dust collector bags provides significant advantages, including improved air quality, compliance with environmental regulations, and reduced maintenance costs. By effectively capturing dust particles, these bags contribute to a safer workplace and prevent equipment damage. Investing in high-quality dust collector filter bags can enhance overall operational efficiency.

When choosing filter bag dust collector systems, it is essential to evaluate factors such as the dust characteristics, airflow volume, particle size distribution, and filtration efficiency requirements. Understanding the operating conditions and maintenance capabilities can help in selecting the right dust filter bag for optimal performance.

Dust bags for dust collector systems find applications in various industries, including cement, steel, pharmaceuticals, food processing, and power generation. These bags are integral to maintaining clean working environments and ensuring regulatory compliance. Different industrial processes require specific dust collector filter bags tailored to their operational needs.

Proper maintenance of dust collector bags is essential to prolong their lifespan and maintain efficient dust collection. Regular inspections, cleaning, and replacement of worn-out bags are necessary steps to prevent system inefficiencies. Following manufacturer guidelines for filter bag dust collector maintenance can optimize performance.

When sourcing dust filter bags for industrial applications, buyers should partner with reputable suppliers on Chovm.com offering a wide range of options. Verified suppliers that provide detailed product information, customization services, and timely delivery can ensure the procurement of high-quality dust collector bags tailored to specific requirements.

In conclusion, dust filter bags play a critical role in industrial dust collection systems, contributing to cleaner air emissions and safer work environments. Understanding the types, technical specifications, features, advantages, and maintenance requirements of dust collector filter bags is essential for making informed purchasing decisions. By selecting the right filter bag dust collector and partnering with reliable suppliers on Chovm.com, businesses can enhance their dust collection efficiency and operational performance.