(77 products available)

A Dana water cooler has different types that are mainly based on how the water is cooled. These different types of chillers are usually combined into a single unit for convenience and portability.

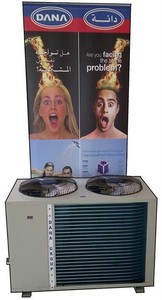

Air-cooled chillers

An air-cooled dana water chiller uses ambient air to cool down the water. It works by circulating air over the condenser coils. The condenser coils are internal components that are kept cool by the flow of refrigerant within them. The coils then release the heat generated from the refrigerant into the environment. This process cools down the water and ice in the compressor using ambient air. Air-cooled chillers are popular because they require little maintenance and are extremely easy to install.

Water-cooled chillers

As implied by the name, water-cooled chillers use water to cool down the refrigerant in the system. The water can come from a cooling tower, evaporator condensers, or city water. The water then absorbs the heat generated from the refrigerant and releases it into the environment. Water-cooled chillers have high cooling capacities. In addition to taking up less space compared to air-cooled chillers, they also perform more efficiently, especially in large-scale operations. However, water-cooled chillers require more maintenance and complex installation procedures.

Wracker chillers

Wracker chillers are also referred to as screw chillers. They have a unique design that includes a screw compressor. Due to its increased size and capacity, the screw compressor brings a lot of power. Larger buildings and industrial spaces mostly use wracker chillers because they can handle high loads effortlessly. Another benefit that the cooling system offers is that it works quietly compared to other chillers. It is ideal for spaces that need to be silent.

Portable chillers

Portable water chillers are relocation-friendly cooling systems that can be moved from one point to another. They do this conveniently by casting wheels on the base so users can push or drag them comfortably. Most of them are air-cooled, but some variants might be water-cooled. The chillers are ideal for temporary setups and manufacturing processes that require cooling from anywhere.

Specifications of dana water chillers vary depending on the specific features of different models from several manufacturers.

When looking to buy industrial chillers, it is essential to consider the maintenance needs. Choose a chiller that doesn't require frequent maintenance. Only a few parts of the chiller need regular care, while some need to be checked occasionally. Some necessary daily maintenance tasks include:

Others parts that require maintenance every once in a while include:

While some chiller parts require frequent maintenance, others need to be checked occasionally. Important parts to inspect regularly include:

Finally, some parts of the chiller need professional help. These include:

Food Industry:

In the food industry, cooling systems are important for preserving food, processing it, and keeping it fresh. Water chillers help maintain food quality, extend shelf life, and make sure that products are safe to eat. Certain meals are frozen via chilling while certain meals, like soft drinks and dairy items, are kept cool to preserve their quality.

Plastic and Injection Molding:

In the injection molding sector, water chillers are widely used. They provide precise temperature control throughout the cooling phase. This results in quick cooling and reduced cycle times. Plastics are used in a wide range of industrial sectors, so the use of chillers will vary depending on the kind of plastic and the molding technology employed.

Pharmaceutical and Biotechnology:

Water chillers play a key role in both the production and storage of drugs and biological compounds for the pharmaceutical and biotechnology sectors. They ensure that the fermentation, reaction, and storage vessels are maintained at the appropriate temperature. This means that the stability, safety, and efficiency of pharmaceutical and biotechnological products will be preserved.

Plastic and Injection Molding:

A key application for water chillers is the cooling of laser cutting machines used in a variety of materials, including acrylic and PVC. These machines use a laser beam to cut and form products precisely. The laser's cooling system needs to work effectively to maintain a constant temperature and ensure that the machine operates smoothly. This helps achieve accurate cutting, as well as preventing overheating and thereby extending the laser's life span.

Data Centers and IT infrastructure:

Water chillers are essential components of cooling systems used in server farms and data centers. They help remove heat from servers, network equipment, and other IT infrastructure to maintain optimal operating conditions. This ensures the continued performance and availability of data center facilities.

Textile Industry:

The textile industry uses chillers to manage the temperature and humidity in production facilities. This ensures the stability and quality of textile items such as fabrics, yarns, and garments.

Laser Cutting Machines:

Water chillers are vital for cooling laser cutting machines used in various materials like acrylic, PVC, and others. These machines rely on a focused beam of light to make precise cuts. Proper cooling is necessary to maintain consistent cutting quality and prevent overheating of the laser and other components.

Laser Etching Machines:

Chillers play an essential role in the operation of laser engraving machines. They are used to engrave intricate patterns and designs on a variety of materials, such as metal, wood, glass, and plastic. The lasers used in these engravers generate heat as they function, and this heat must be removed in order to avoid overheating and maintain the engraving's accuracy and precision. For the lasers to function effectively and create quality engravings, cooling systems are employed to regulate their temperature.

Business buyers should consider several critical factors before investing in a large-scale Dana water chiller. They need to ensure that the chillers they are purchasing have the capacity required by the application to function efficiently and avoid overheating.

They should analyze the expected annual cost of the chillers. Compare the energy efficiency rating of the coolers, which impacts the application's total operating cost. A more efficient cooler may have a higher upfront cost, but it can offset the amount in the annual energy bill.

Consider space constraints in the industrial facility. Depending on the size and weight of the equipment, the water chiller may require additional structural changes to accommodate it. If there isn't much space available, opt for compact chillers or those that can be installed at the rack.

Ensure the durability and build quality of the Dana water chiller selected, especially if it will be exposed to extremely high or low temperatures. Despite the high upfront cost, the chiller will last years because it does not require frequent replacement.

Select a water chiller that offers connectivity features, such as remote monitoring, system integration, and other advanced features, as these can play a significant role in managing and monitoring the performance of the chilling system.

Many factors impact the performance of a Dana water cooler, including, but not limited to, the surface area, heat transfer coefficient, thickness of tubing coils, and the fin. Ensure that the cooler selected has the optimal build to offer the fastest cooling.

The water chillers need to be easy to use, maintain, and install, as frequent downtime can impact the overall production process. A Dana water cooler with clear user manuals, simple installation steps, and accessible components will reduce the cost of technical assistance.

Lastly, consider the warranty and after-sales support. Choose a manufacturer that offers reliable customer service and technical support. Select a chiller with a good warranty that covers parts and labor for repairs.

Q: What is the difference between vapor-compression and vapor-absorption chillers?

A: The two processes are different. Vapor-compression chillers use mechanical devices like electric motors or driving gears to compress refrigerant vapor. On the other hand, vapor-absorption chillers utilize heat energy to make the refrigerant evaporate and absorb the heat.

Q: Can a water chiller be repaired if it is broken?

A: Yes, if it is broken, it can be repaired. However, some factors will need to be checked first before deciding to repair it. One of the most important factors to consider is the extent of the damage or issue. If the water chiller is not a serious issue like a broken fan or a faulty thermostat and individual parts can be repaired, then a repair may be a good option. If there is serious damage like a broken compressor, refrigerant leak, or complete failure of the system, then it may not be a good option. Also, the cost of the repair should be looked at. If the repair cost is significantly lower than the cost of a new chiller, then it is worth it. Lastly, the age and condition of the chiller should be considered. If it is quite old and not very effective, then it may be better to replace it with a more efficient model.

Q: How long does it take to install a new water chiller?

A: Installing a new water chiller can take several hours or days, depending on some factors. The type and size of the water chiller will influence the installation. Bigger chillers will take longer to install compared to smaller models. The condition and setup of the existing system will also influence if the water chiller being installed is compatible with existing cooling and refrigeration systems. If new electrical and plumbing connections have to be made, it will certainly take longer to install. The experience of the technicians will also determine how long it takes to install the water chiller. If the technician is experienced and skilled, it will take less time.

Q: How do water chillers contribute to energy efficiency?

A: Water chillers are actually the backbone of energy efficiency in many industrial plants and facilities. They help to maintain optimal operating conditions and prevent overheating of equipment. This in turn reduces the need for cooling. Water chillers also provide precise temperature control for processes that are cooling-dependent. This improves product quality and minimizes waste. With these processes being properly cooled, there is less use of energy. Furthermore, many water chillers come with features that are energy-saving like variable-speed drives and high-efficiency compressors.