Introduction to Creform Pipes

Creform pipes are specialized structural components widely used in various industries for building customizable frameworks and material handling systems. Known for their versatility and strength, Creform pipes serve as the backbone for creating operational efficiencies in manufacturing, assembly lines, and warehouse settings. Their modular nature allows businesses to adapt their structures to meet evolving needs, boosting productivity and reducing downtime.

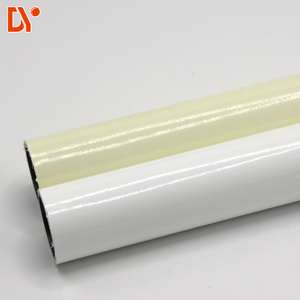

Types of Creform Pipes

Creform pipes come in various types to cater to different applications and requirements. The main types include:

- Standard Pipes: These are the foundational elements used in most Creform systems, designed for general applications.

- Heavy-Duty Pipes: Featuring increased wall thickness, these pipes support heavier loads and are ideal for robust applications.

- Lightweight Pipes: Made from lightweight materials, these pipes facilitate easy maneuverability and are perfect for less demanding structures.

- Angle Pipes: Utilized to create framework at specific angles, these pipes enhance flexibility and design possibilities.

Applications of Creform Pipes

Creform pipes are extensively utilized across various sectors due to their adaptable nature. Key applications include:

- Manufacturing: Building ergonomic workstations and efficient assembly lines to optimize workflows.

- Warehouse Management: Designing storage solutions and material handling systems that comfortably fit available space.

- Retail Displays: Structuring display units that are both functional and visually appealing to enhance the customer experience.

- Automotive Industry: Creating jigs, fixtures, and special tools to streamline production processes.

Advantages of Using Creform Pipes

Investing in Creform pipes offers a multitude of benefits that can elevate your operational efficiency. Here are some of the key advantages:

- Modularity: The ability to easily reconfigure and adapt systems without significant downtime or expense.

- Cost-Effective Solutions: Eliminating the need for heavy machinery or complex custom-made structures reduces overall costs.

- Lightweight & Durable: Made from high-quality materials that balance both lightweight characteristics and strength, ensuring longevity.

- Easy Customization: Allows users to create tailored solutions that fit specific operational requirements, fostering innovation.