(18427 products available)

There are three main types of construction frame scaffolding: modular, single, and double. Construction frame scaffolding is temporary support used in construction industries. It is a framework that supports buildings or structures under construction. The construction frame scaffolding is made of durable materials such as steel or aluminum. It is crafted into poles, beams, and boards that are assembled to provide support.

The construction frame scaffolding comes in different types, as explained below:

Modular Scaffolding

Modular or prefabricated scaffolding is a type of construction frame scaffolding. It consists of standard components that can be assembled into different structures. This construction frame scaffolding comprises frames, cross braces, clamps, and accessories. The components are manufactured using advanced technology. Modular scaffolding is commonly used in industrial, commercial, and large-scale construction projects. It is also suitable for projects requiring quick assembly and disassembly. The advantages of modular scaffolding include enhanced stability and safety. It also has reduced labor costs and assembly time.

Single Scaffolding

Single or ordinary scaffolding is a type of construction frame scaffolding used for brickwork. It comprises a single row of standards that are fixed to the wall of the structure under construction. The construction frame scaffolding is independent of the wall it supports. Its components include ledgers, standards, putlogs, and transoms. Single scaffolding is less costly than other types of construction frame scaffolding. It is ideal for projects with a limited budget.

Double Scaffolding

Double scaffolding is also known as stone scaffolding. It is a type of construction frame scaffolding used for stone masonry works. It has two rows of standards to bear the scaffolding loads. The two rows of standards are securely tied using ledgers and transoms. Double scaffolding is more expensive than single scaffolding. This is because it requires more materials and time to construct. However, it provides more excellent stability and support.

Robust Structure:

Construction frame scaffolding is strong and durable. It's made of robust materials like galvanized steel or aluminum, which can hold a lot of weight. This scaffolding won't bend or break while workers are on it or with the materials they are using. The pipes/frames are often thick, around 1.5 inches in diameter, giving them excellent strength. This robust construction ensures safety on the project site.

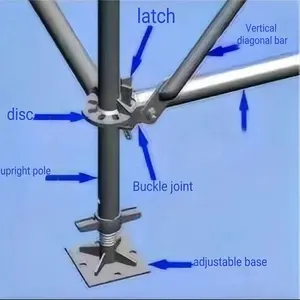

Modular Design:

Construction frame scaffolding has a modular design. It consists of individual parts and components like pipes/frames, couplers/joints, and platforms/decks. This design allows the scaffolding to be customized and adapted to different building projects. The scaffolding can be assembled in various configurations to suit the needs of the project. This modularity increases its usability and efficiency.

Height Adjustability:

This type of construction frame scaffolding can be made taller or shorter as needed. The vertical pipes/frames come in different lengths, so the scaffolding can be adjusted to the right height for the job. Construction frame scaffolding is often used for projects of varying heights, and this adjustability feature makes it safe and stable no matter how high the building is. Workers can safely reach the top of any structure to complete their work.

Stability and Safety:

Construction frame scaffolding is very stable and safe for workers to use. It has cross braces that form a strong 'X' pattern, making the scaffolding support more rigid and resistant to wind. The scaffolding also has outriggers/extensions that can be added to increase stability, especially on taller structures. Additionally, scaffolding is anchored to the building. This anchorage prevents it from tipping or falling over while workers are on it.

Versatility:

This type of construction frame scaffolding is used in many different industries and for various jobs. It's commonly used in construction for building and repairing structures. However, it can also be used for maintenance work, painting, plastering, and electrical jobs. This versatility allows construction frame scaffolding to be used in many projects.

Construction Projects

Frame scaffolding is mainly used in construction projects. It offers support and a secure platform for workers. Whether it's low-rise buildings or high-rise structures, frame scaffolding can be set up quickly. It allows workers to access different heights. Tasks like framing, roofing, and siding installation can be completed efficiently.

Bridge Construction and Maintenance

Frame scaffolding is used in bridge construction and maintenance. It provides access to the bridge deck and underneath sections. This enables workers to carry out tasks like inspection, painting, and repairs. Frame scaffolding ensures workers are safe when working on these structures that are elevated and hard to reach.

Commercial Building Projects

Frame scaffolding is a common sight at commercial building sites. It offers a stable and secure platform for tasks like masonry, glazing, and metal decking. The adjustable nature of frame scaffolding conforms to different building heights and shapes. This ensures workers operate at the required elevation safely.

Industrial Facilities

Frame scaffolding is used at industrial facilities like refineries, factories, and power plants. It provides access to complex structures and high areas. Workers conduct maintenance, inspections, and installations. The open-frame design of the scaffolding allows workers to interact with the machinery and perform tasks efficiently.

Emergency Rescue Operations

Frame scaffolding is used in emergency rescue operations. It offers a quick and secure solution to access stranded individuals in elevated areas. Rescue teams set up the scaffolding quickly to create a safe platform for rescue. The adjustable nature of the scaffolding accommodates different heights and distances.

Painting and Facade Maintenance

Frame scaffolding is used for painting and maintaining building facades. It offers a stable platform for workers to carry out tasks at different elevations. The open-frame design ensures workers have enough space to handle painting tools and materials. Frame scaffolding can be moved along the building perimeter to facilitate continuous work.

When choosing the right scaffolding for sale, it is important to consider a few things. Here are some of them:

Type of Project

Both single and double frame scaffolding can be used for different construction projects. Choosing the right one depends on the type of project. For example, double frame scaffolding is ideal for high-rise construction projects, while single frame scaffolding is suitable for small projects.

Material

Construction frame scaffolding comes in different materials, such as steel, aluminum, and wood. Steel is the preferred choice for most construction projects since it has a high load capacity and is durable. However, aluminum can also be considered because it is lightweight and rust resistant.

Portability

If the construction project requires moving the scaffolding to different locations, it is important to consider the portability of the scaffolding. Aluminum construction frame scaffolding is more portable than steel since it is lightweight.

Height and Load Capacity

When buying construction frame scaffolding, it is important to consider the height and load capacity. Different scaffolds can reach different heights, so choosing a scaffold that will reach the required height for the construction project is important. Additionally, load capacity is crucial since it determines how much weight the scaffold can carry. It is important to choose scaffolds with a high load capacity to carry construction materials and workers.

Compliance with Safety Standards

Safety should always come first when choosing construction frame scaffolding. Therefore, it is important to ensure that the scaffolds comply with safety standards. This can be done by checking the certifications and reviews of the scaffolds before buying them.

Q1: What is the maximum height of frame scaffolding?

A1: There is no standard maximum height for construction frame scaffolding because it varies according to the project requirements. However, the United Kingdom Health and Safety Executive (HSE) states that any frame scaffolding exceeding 6 meters in height should be inspected by a qualified scaffolder. In other regions, scaffolding above a certain height, usually 10 feet, also requires additional support and bracing to ensure stability.

Q2: How is frame construction scaffolding erected and dismantled?

A2: Erecting and dismantling construction frame scaffolding requires careful planning and adherence to safety guidelines. Erection involves assembling the components, securing them, adding fittings, and ensuring structural integrity. Dismantling should be done in reverse order while maintaining safety. A qualified scaffolding supervisor should oversee both processes.

Q3: How many types of construction frame scaffolding are there?

A3: There are two main types of construction frame scaffolding: single and double frame scaffolding. Single frame scaffolding has standards on one side, while double frame has them on both sides for additional support and stability.

Q4: What are the safety requirements for construction frame scaffolding?

A4: Some of the safety requirements include regular inspection of the scaffolding, using qualified personnel for erection and dismantling, ensuring adequate bracing and support, and using quality materials. Others are following recommended height regulations, using safety fittings, and providing safety gear like helmets and harnesses.

The web search volume for the keyword "construction frame scaffolding" has remained consistently low over the past year, with an average monthly web search volume of 10. This keyword has experienced a significant one-year and three-month change, both showing a -100% decline. The data over the last twelve months reveals a pattern of stability in search frequency, except for two months where the volume dropped to zero.

Analyzing the web search volume trends more closely, the keyword "construction frame scaffolding" shows minor fluctuations, with the lowest points occurring in August and November 2024 where web searches temporarily ceased. The consistent web search volume of 10 in other months suggests a steady, albeit small, interest in this keyword. This pattern indicates that while the topic is not experiencing growth or increased interest, it also isn't completely abandoned by searchers.

The reasons behind these trends are not explored in this analysis, but the data clearly shows a niche interest in this keyword. The construction and real estate category it belongs to might influence its limited web search volume, possibly due to the specialized nature of construction frame scaffolding, which is not a mainstream topic but rather a specific need within the industry. This analysis highlights the importance of understanding niche markets and their search behaviors, which can be crucial for targeted marketing and content strategies in the construction and real estate sectors.