(187074 products available)

Chillers are essential equipment in various industries, providing cooling solutions for machinery, processes, and environments. One of the most common types is the chiller, which is widely used for its efficiency and versatility. Whether it's for industrial applications, commercial buildings, or medical facilities, chillers play a crucial role in maintaining optimal temperatures.

There are different types of chillers available, each designed for specific purposes. Water chillers are commonly used in HVAC systems to cool water for air conditioning. On the other hand, air-cooled chillers are self-contained units that use air to remove heat from the refrigerant. For specialized needs like ice baths, water chillers for ice bath offer precise temperature control. Industrial chillers are heavy-duty units designed for large-scale cooling applications in manufacturing and processing plants.

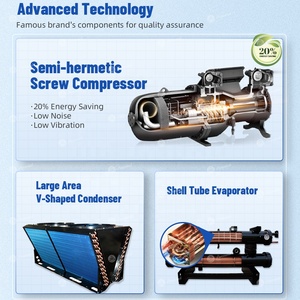

When selecting a chiller, it's essential to consider technical specifications such as cooling capacity, power requirements, and efficiency. Water chillers typically have a cooling capacity ranging from 1 to 1000 tons, making them suitable for various environments. Air-cooled chillers are known for their compact design and ease of installation, making them ideal for spaces where water availability is limited. Industrial chillers are equipped with heavy-duty compressors and components to withstand continuous operation under demanding conditions.

The use of chillers offers several advantages, including energy efficiency, precise temperature control, and scalability. Water chillers are energy-efficient alternatives to traditional air conditioning systems, reducing overall energy consumption. Air-cooled chillers are easy to maintain and operate, making them cost-effective solutions for small to medium-sized applications. Industrial chillers provide precise temperature control, ensuring consistent performance in critical processes.

Chillers find applications across various industries, including food and beverage, pharmaceuticals, plastics, and more. In the food industry, chillers are used for cooling during food processing and storage. Pharmaceutical companies rely on chillers to maintain specific temperatures for drug manufacturing. Plastics manufacturers use chillers to cool molds and maintain product quality.

When choosing a chiller for your specific application, consider factors such as cooling capacity, energy efficiency, maintenance requirements, and space constraints. Water chillers are suitable for applications requiring precise temperature control, while air-cooled chillers are ideal for locations where water availability is limited. For heavy-duty industrial applications, industrial chillers with robust construction and high cooling capacity are recommended.

Proper maintenance is crucial to ensure the longevity and efficiency of your chiller. Regular inspection of components, cleaning of filters, and checking for refrigerant leaks are essential tasks to keep your chiller running smoothly. For water chillers, monitoring water quality and flow rates is important to prevent scaling and corrosion. Air-cooled chillers should have their fans and condenser coils cleaned regularly to maintain optimal performance.

In conclusion, chillers are indispensable cooling solutions for a wide range of industries and applications. Understanding the different types of chillers available, their technical specifications, advantages, and maintenance requirements is essential for selecting the right unit for your specific needs. Whether you require precise temperature control in a laboratory setting or heavy-duty cooling for industrial processes, there is a chiller designed to meet your requirements.