(26647 products available)

Chicken feed processing models are categorized, and they each have particular attributes and functions appropriate for various operational requirements. Understanding these types facilitates buyers in making informed decisions based on production capacity, feed type, and other crucial factors.

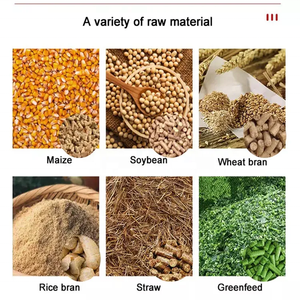

The hammer mill and mixer combination is popular in small- to medium-sized operations. The hammer mill grinds the ingredients into fine particles, ensuring a uniform texture. The mixer then blends these ground materials to create a cohesive feed mixture. This setup is useful for producing mash or finely mixed feed, especially where diverse ingredient types necessitate thorough mixing. Ingredient types include corn, soybean meal, and wheat.

The ring die pellet mill is designed for large-scale production of pelletized chicken feed. Its advanced die and roller setup enable the processing of a broad spectrum of materials, including tough agricultural residues and high-protein seeds. The ring die's longevity makes it suitable for vast businesses where extended use without replacement is needed. The high compression within the machine also guarantees that feed is nutritionally dense and stable for longer periods.

This type is especially valuable for producing floating fish feed variations. Its unique design allows for the production of feed with varying densities and floating capacities by adjusting the screw speed and temperature settings. Aquatic feeds, which require different textures and floating properties, benefit from this technology.

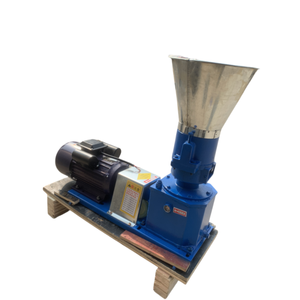

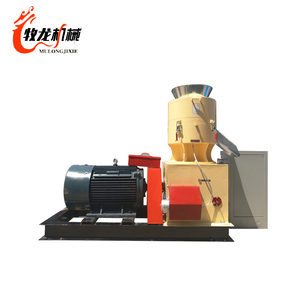

The flat die pellet mill is suitable for small to medium-sized businesses. This mill is adaptable, processing diverse materials like corn, wheat bran, and rice husks into pellets. While it supports smaller operations, it can also cater to larger businesses requiring a temporary increase in production. It's particularly useful for businesses that grow their feed ingredient supply on-site.

The primary aim of processing chicken feed is to heighten the nutritional value, safety, and digestibility of the feed given to poultry. However, there are other commercial uses.

Processing equipment enables businesses to create tailored feed formulations by using diverse seeds, grains, and supplements. This flexibility allows them to respond to specific nutritional needs of various poultry.

By producing their own feed or processing locally sourced materials, businesses can significantly lower feed costs.

Many feed processing setups, such as hammer mills and pelletizers, are designed to incorporate by-products from other agricultural processes. This approach not only reduces waste but also lowers the cost of feed production.

For instance, spent brewers yeast from breweries, fish meal from seafood processing, or used cooking oil from the restaurant industry can be integrated into feed formulations. This practice not only minimizes feed costs but also contributes to a more sustainable agricultural system by reusing materials that would otherwise be discarded.

As global chicken feed needs rise, businesses processing feed in bulk can capitalize on international markets, particularly in nations with less developed feed infrastructure. This boosts the local economy and generates income for the businesses.

One major benefit of processing chicken feed is this. Methods such as pelleting or extruding improve the feed's storage capacity, which is especially significant for regions where feed must be transported over long distances. Improved storage reduces waste and allows for better inventory management. Additionally, processed feeds maintain their nutritional value over longer periods, ensuring that chickens receive consistent and reliable nutrition, regardless of availability.

Understanding the key features and specifications of feed processing machines ensures businesses choose equipment that meets their production requirements effectively.

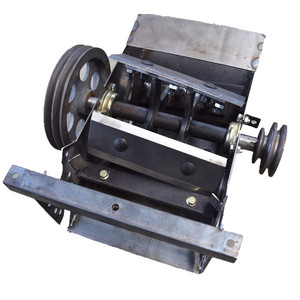

Size Reduction

The hammer mill's primary function is to reduce grain size, helping to increase its surface area and enhance digestibility. This guide enhances the nutritional value, making it easier for chickens to absorb essential nutrients.

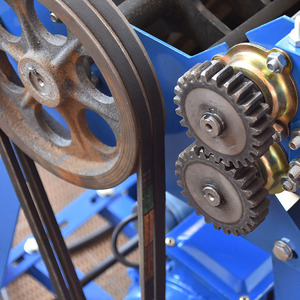

Improved Pellet Quality

The ring die pellet mill predominantly affects pellet feed quality. It ensures uniformity in size and shape, leading to better feed intake among chickens. High-quality pellets decrease segregation and wastage during transportation and feeding.

Enhanced Nutrition

High temperatures used in processing help eliminate harmful bacteria and pathogens present in raw ingredients. This heating process enhances nutrient availability, ensuring that chickens receive maximum nutritional benefits.

Energy Efficiency

Modern chicken feed machines are built with energy-saving measures. For instance, the flat die uses less power than the ring die because of its simple setup. The screw extruder processes the feed using less thermal energy compared to older heating methods, making it suitable for businesses concerned about high energy costs.

When selecting appropriate chicken feed processing machines, there are several key requirements that businesses should keep in mind.

Different machines cater to distinctive output capacity requirements. This means small-sized feed-making businesses can go for a flat die pellet mill. However, large feed processing businesses should use a ring die pellet mill, which has a higher production capacity.

Financial implications also matter a lot when choosing processing machines. These machines have distinguished prices. Some may be eminently costly, but they offer lots of forecasted profits. Others are relatively cheap, like the flat die pellet mill, but they still produce some profits. Only select machines whose cost can be covered by the budget. This entails weighing all the options available and choosing one that offers significant returns.

Some machines work well with certain feed types. A screw extruder is suitable for feeds that need different textures and densities. On the other hand, a ring die pellet mill works excellently in producing feed pellets that are nutritionally packed. Businesses producing more layers feed can use a feed mill machine that is specifically made for layer feed.

As energy costs continue to rise, selecting machines that offer high energy efficiency is essential. The extruder and pellet mill are more energy efficient than older grinding and mixing methods. This helps cut down on long-term energy costs and makes feed production more sustainable for the future.

Consider the long-term maintenance needs of any chosen machine. Machines that are more energy-efficient and have more advanced technology tend to have lesser maintenance needs. It has to be the case for the machines that are recently invented, but those that have been used for a long have the probability of getting a new part to replace.

A1: All hens require the same type of feed, but the feed must be fortified with different minerals and vitamins to help layers produce eggs and broilers gain weight. Layer feeds include oyster shells for calcium, which thickens the eggs. Broiler feeds contain more protein to help chickens grow muscular tissues rapidly.

A2: Some visible signs of bad feed are the presence of mold, an unusual rancid smell, changes in color, and the presence of insects. Bad feed can also be felt. If there is bad-quality feed, the chickens won't lay any eggs. Also, they will look for other food sources, and if they eat spoiled food, they can get a lot of infections.

A3: Wet chicken feed can be used again, but only if it has not been tempered with already. When recycling wet feed, scoop out all the feed additives that have already been tampered with and add new feeds to them. Reuse only feeds that have not been spoiled or have not spent too much time outside.

A4: The main aim of feed processing is to enhance the nutrition, safety, and digestibility of feed given to poultry. Processing improves the feed's nutritional value, making it easier for chickens to absorb essential nutrients.

A5: These include size reduction, improved pellet quality, increased nutritional value, energy efficiency, and maintenance. Specific machine features address the unique needs of chicken feed processors.