(25 products available)

Cable pvc 2 x 10 mm2 has various uses, so it comes in different types.

PVC Insulated Cables

These cables come with a PVC plastic coat. The coat keeps electricity inside the wires and stops shocks or fires. People like these cables because they are strong and keep working in hot or cold weather and wet places. Most homes and workplaces use electrically powered devices, lighting, and circuits through PVC insulated cables.

PVC Sheathed Cables

PVC sheathed cables have a thicker plastic wrap over other wire coats. This wrap improves protection from cuts, chemicals, and dampness. Many factories and building sites use these cables, where machines and tools need safe wiring. They also help supply electricity to outside areas such as balconies or sheds.

PVC Flat Cables

Flat cables look like thin strips or lines. Their shape allows many cables to stack or line up neatly side by side. People use PVC flat cables in TVs, sound systems, and computer gadgets. These devices need lightweight wiring to connect inner parts. The flat design also works well for tight spaces.

Flexible PVC Cables

Flexible PVC cables are PVC-coated copper wire strands. The strands bend easily without breaking or getting damaged. People often use these cables in devices that need wires to shift or twist, like conveyor belts. They also work well for moving parts that require an electric motor to run.

High Voltage PVC Cables

High tension PVC cables can transmit a large amount of electric current. Moreover, these cables have multiple layers of insulation to protect them from high voltage. These cables are used in power generation and transmission stations.

When selecting a PVC cable, several factors must be considered.

Budget

PVC cables generally cost less than other types, especially those with extra protection. People choose them for savings. However, premium-quality PVC or special cables may go above budget yet offer safe and long-lasting benefits in the right conditions. It is good to weigh costs along with how important safety and durability are for the project before deciding.

Durability

The long-lasting nature of PVC cables depends on their use. It may need tougher wires or coatings for construction sites with hazards or rough conditions. Home wiring does not require as strong materials. It is important to examine the environment where the cable needs to perform and how long it must work without needing a replacement.

Electrical Needs

The amount of current or voltage will determine which cable to use. Many PVC cables are fine with standard home electricity or low voltage. Industrial machines require more heavy-duty varieties. Larger diameter cables handle greater power. Checking specifications ensures that the wire selected matches the electrical load it must safely carry.

Length

Long-distance cable runs adapt differently from short trips. Thinner PVC cables overheat or lose energy when carrying too much power over a long stretch. Wider wires are also better for lengthy installations. The voltage drop must be considered for lengthy cable runs to avoid underpowering systems at the end of the line.

Installation Conditions

PVC cables can be safely fitted in various spaces. They are easy to roll out overhead, underground, or within building walls. Some have special coatings that tolerantly resist flames or harsh chemicals, making them suitable for risky locations. The installation area should be analyzed to identify whether any further enhancements are required to safeguard the cable effectively.

The durability of PVC cable depends on various factors.

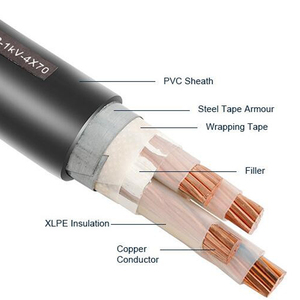

Multiple Insulation Layers

PVC cables have layered coatings. They protect the wire inside from problems like heat or getting shocked by electricity. Some cables even have extra layers made from rubber or fabric to help keep them working longer, especially where conditions are hard.

Water and Chemical Resistance

The outside coat of PVC shields the wires from water and other liquids that could cause damage. This makes it great for areas where cables might get wet or meet harsh liquids. Certain PVC cables stand up well to industrial-grade liquids and gases that other wires can't handle as easily.

Heat Tolerance

PVC cables can work between -15 and 70 °C. This chilly and warm temperature range lets the cables handle different climates and machine conditions without breaking down. Compared to other types, PVC cables are also less likely to melt if temperatures rise too high.

Flexibility

Cables with PVC coats usually contain tiny strands of copper. This thin metal bends more easily than thicker pieces. The smaller, flexible wires permit movements without breaking, unlike stiffer cables that snap faster when artfully fitted into tight spaces or if they have to bend.

Abrasion Resistance

Many PVC cables test well against scrapes and cuts. They frequently undergo rubbing tests that check how long the cable lasts when acted upon by abrasive substances or being moved around. Rough environments try to damage the cable less when abrasion-resistant designs are selected.

Customers use PVC cables for various applications.

Home Wiring

PVC insulated cables have widespread application in house electrical wiring. Their robustness and affordability make them suitable for wiring lighting, power outlets, and appliances. Moreover, the PVC insulation provides safety by preventing electrical shocks and short circuits.

Industrial Machinery

People often apply PVC Sheathed cables to power industrial machinery in factories. Their capacity to endure harsh working conditions and resist chemical exposure makes them well-suited for this role. The PVC sheath protects the wires from damage caused by dust, debris, and machine vibrations.

Office Equipment

Thanks to their flexibility and thin profile, PVC flat cables are ideal for wiring office equipment such as computers, printers, and telecommunication systems. These cables fit easily into the tight spaces between devices and manage energy transfer efficiently.

Construction Sites

Construction sites require reliable and flexible cables to power tools and equipment. Flexible PVC cables meet this need. Their ability to withstand constant bending and movement without damage enables smooth operations in dynamic environments.

Power Distribution

High voltage PVC cables are widely used for electrical transmission and distribution. Their design allows them to safely carry large amounts of electrical current. Moreover, the multiple layers of insulation enhance their protection, making them ideal for power grid applications.

A1: The "10 mm²" tells how thick the wire inside the cable is. A wider wire can carry more electric power safely. This cable works well for many household needs and small businesses.

A2: Yes, PVC cables are good at protecting wires from moisture and liquids. This makes them well-suited for outdoor use, basements, and places where they could get wet. It is important to choose the right cable for the specific environment.

A3: Yes, many flexible PVC cables are designed tough enough for factory and construction site conditions. They handle constant bending and exposure to chemicals very well.

A4: Normal wiring can lose energy if the current has to travel far. However, PVC cables work well for short or medium distances. For longer runs, thicker wires reduce energy loss.

A5: PVC wiring is rated to last around 20-30 years in good conditions. It holds up even longer when sheltered from the weather. Some types last even more than 50 years in protected places.