(74783 products available)

Bricks are essential raw materials in the construction industry. Bricks manufacturing machines are used to produce various types of bricks and block. Different types of bricks-making machines use different types of technology and processes to manufacture bricks to meet various needs and requirements. Here are some of the most commonly used bricks manufacturing machines:

Clay brick making machine

The machine is used to manufacture bricks from raw materials such as clay, shale, and coal gangue. The material is first crushed and then mixed with water until it reaches a consistent mixture. The next stage is extruding, where the mixture is pushed through a mold, and once it's been cut into strips, those strips are then placed onto green belts for drying and firing, where the drying process hardens the material into brick form. There are several types of clay brick machines, including the vacuum extruder, cutter, wire, and double extrusion machines.

Concrete block-making machine:

A concrete block-making machine uses raw materials such as cement, sand, stone, and water to manufacture concrete blocks and other related solid blocks for construction purposes. Those materials are then combined, mixed, and cured into blocks for wall-building, landscaping, and other construction needs. This machine comes in two main types: semi-automatic and fully automatic.

Fly ash brick making machine:

The fly ash brick-making machine uses an industrial by-product known as fly ash, which is produced from the burning of pulverized coal in power plants. Other raw materials used are lime, sand, and water. Those materials are combined and mixed in the machine before being shaped and cured into lightweight, high-strength bricks with excellent fire resistance and durability.

Interlocking brick making machine:

An interlocking brick-making machine makes bricks that are self-locking. These self-locking bricks don't require mortar for construction, which makes assembly easier and speeds up the building process. The legs and panels on these bricks provide stability and interlock with each other, while the different shapes and sizes allow for varied and interesting architectural designs. The raw material for this kind of brick maker includes clay, lime, and cement, among others.

Specifications for bricks manufacturing machines will vary depending on the type of machine and what kind of bricks it makes.

Maintenance of bricks manufacturing machines:

Before starting any maintenance operations, it is very important to read the manufacturer's maintenance instructions carefully and never operate the machine without the right manuals.

While each machine has its own specific maintenance requirements, generally speaking, the following advice should be adhered to:

Construction Industry:

Bricks manufacturing machines are primarily used in the construction industry to produce bricks that are used for a variety of building projects, including residential homes, commercial buildings, roads, infrastructure projects, and more.

High-Demand Regions:

Areas with a rapid increase in population and urbanization are often in high need of construction materials. Automated bricks manufacturing machines are especially useful in these areas because they can quickly and cost-effectively produce large amounts of brick.

Self-Sustaining Construction Projects:

Large construction projects that also require a lot of bricks can benefit from having a bricks manufacturing machine on-site. This could include building a new community, a big hotel, or an important piece of infrastructure like a bridge or road. Having a machine on-site could lower costs and make it easier to get the building materials needed.

Remote Locations:

Sometimes it's hard to transport construction materials to the location of a building project. This is especially true for sites that are far away or in a remote area. In these situations, having a bricks manufacturing machine close by could help solve the problem of supplying building materials.

Eco-Friendly Construction:

Bricks manufacturing machines aren't just for producing bricks. They can also be used to make sustainable building materials, like using waste as an ingredient. This helps support green construction practices.

When looking to invest in a bricks manufacturing machine, buyers need to consider several critical features and parameters to ensure that the machine meets their unique needs.

Production Capacity

Production capacity is the amount of bricks a machine can produce in a specific period. Buyers should choose a machine with a production capacity that matches their demand. To meet future expansion requirements, it is also advisable to consider a machine with the potential for a higher production capacity.

Automation

Automation is the use of machines to do tasks without human intervention. The level of automation in a bricks-making machine can differ a lot, from fully automatic to semi-automatic. To meet their specific needs, buyers should consider the machine's degree of automation and choose between semi-automatic and fully automatic brick manufacturing machines.

Raw Materials

The type of raw materials a brick-making machine can utilize can vary significantly. Buyers should choose a machine that corresponds to the type of raw materials they plan to use. They must also ensure that the machine can process those materials effectively.

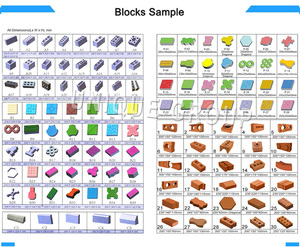

Brick Types

Brick type refers to the distinct shapes and sizes of bricks manufactured for various construction purposes. Buyers have different needs depending on their intended use. They should look for a brick-making machine that can produce the sizes and shapes they require.

Energy Efficiency

Energy efficiency refers to how well a machine converts energy into productive output without wasting too much energy. Machines with high energy efficiency save operating costs and contribute to environmental sustainability.

Q1: What kind of material does a bricks manufacturing machine use?

A1: It depends on the type of machine. Generally, bricks manufacturing machines make bricks from clay, fly ash, slag, or cement. However, specific machines may accept other materials like sand, stone powder, Gangue, Lime, or Brick waste.

Q2: Can the bricks manufacturing machine make customized bricks?

A2: Yes. The bricks manufacturing machine can make different types of bricks, such as hollow, porous, double-skinned, insulation hollow, etc. Business buyers can customize the bricks based on their needs.

Q3: What is the production capacity of a bricks manufacturing machine?

A3: It varies from machine to machine. Generally, the capacity ranges from 2,000 to 6,000 pieces per 8 hours. Some large-scale machines can produce more than 10,000 pieces in the same period.

Q4: Does the bricks manufacturing machine need special installation?

A4: Some machines are standalone units and do not need special installation. Bricks buyers can refer to the supplier's instruction manual or consult with professionals to ensure the proper and safe use of the machine. However, some bricks manufacturing machines require special installation and several configurations.

Q5: What is the power requirement for a bricks manufacturing machine?

A5: The power requirement varies according to the type and size of the machine. Generally, a bricks manufacturing machine requires between 5 and 50 kilowatts of power. Machines with automatic systems and higher production capacities have higher power requirements. They may need between 20 and 100 kilowatts of power.