Types of branded chillers

A chiller is an essential component of the cooling system of a building or process. It absorbs heat from its surroundings and expels it to maintain a specific temperature. There are different types of chillers. The main categories are: absorptive chillers, which use absorption refrigeration cycles powered by heat; electric motor-driven chillers, which rely on electric motors for their cooling power; centrifugal or wheel-based chillers, which utilize centrifugal force to separate and expel heat; and screw chillers, whose compressors are driven by screws that rotate at variable speeds to control the amount of refrigerant circulated in the system.

Within these main categories, different types exist. For example, both the centrifugal chiller and the screw chiller fall into the mechanical chillers category. Mechanical chillers mostly utilize the refrigerant evaporation technique to absorb heat from their environment. A refrigerant is a special fluid that can absorb heat from the chilled water. After absorbing the heat, the refrigerant undergoes evaporation to form vapor. The vapor is then compressed into high-pressure and high-temperature gas using a compressor. Subsequently, the gas is allowed to cool and condense into liquid, releasing the absorbed heat into the surrounding environment.

Centrifugal coolers use a centrifugal force-based compression mechanism to pump and compress the refrigerant. They are preferable for large cooling capacity needs, such as data centers, manufacturing facilities, hospitals, and schools. On the other hand, screw coolers utilize a screw rotor compression mechanism. They are suitable for medium- to-large-sized spaces requiring a consistent and dependable cooling capacity. It's worth noting that both the screw and centrifugal kinds are preferred refrigerant compressors because they are energy efficient, low maintenance, and designed to last long.

Other kinds of chillers include:

- Absorption chillers: Absorption chillers use a refrigeration cycle driven by thermal energy. This thermal energy can be sourced from waste heat, natural gas, steam, or hot water. Absorption chillers are suitable for applications where waste heat is readily available or in situations where electrical demand needs to be reduced during peak periods.

- Modular chillers: Modular chillers are chillers that consist of several smaller cooling units, or 'modules,' instead of just one large one. Each module operates independently but can be combined with others to provide the required cooling capacity. Modular chillers are flexible and scalable, which means they can adapt easily to changing cooling demands by adding or removing modules as needed.

- Heat recovery chillers: Heat recovery chillers are a type of chiller that recovers waste heat from the chilling process and utilizes it for heating purposes. This is, without a doubt, a great addition to the cooling system that improves energy efficiency by catering to simultaneous cooling and heating needs. Heat recovery chillers are ideal for applications where cooling and heating are required concurrently, such as in commercial buildings, industrial processes, or HVAC systems.

- Hybrid chillers: Hybrid chillers combine different cooling technologies into one system, such as absorption and electric-driven chillers. By leveraging the strengths of varying techniques, hybrid chillers provide adaptability and energy savings depending on the available resources and cooling demands.

Specification and maintenance of brands chiller

Specification

- Cooling Capacity: The cooling capacity of the chiller is normally expressed in tons, where 1 ton is equal to the removal of 12,000 BTUs of heat per hour. Chillers come in a variety of cooling capacities to meet the needs of different applications. For example, a 60-ton chiller can remove 720,000 BTUs of heat per hour.

- Compressor Types: Chiller compressor types include scroll compressors, screw compressors, piston compressors, centrifugal compressors, and others. For example, a scroll compressor might use model XN85-3B, which uses refrigerant R410A and has a capacity of 120,000 BTUs.

- Refrigerant: Refrigerants used in chillers, such as R134A, R410A, or R32, are chosen to meet environmental requirements and performance needs. For example, R134A may have a chiller with a cooling capacity of 500,000 BTUs.

- Heat Exchange Method: The heat exchange methods include water to air, water to water, and others, which are chosen according to application needs. For example, a water-to-air chiller might use model WFC-1000, which has a cooling capacity of 1,000,000 BTUs.

Maintenance

- Clean the condenser and evaporator coils regularly to ensure effective heat exchange.

- Check the refrigerant level and replenish it as necessary to ensure proper cooling performance.

- Inspect the compressor and motor for signs of wear and overheating and repair them in a timely manner.

- Perform regular lubrication and oil replacement for the chiller to ensure smooth operation.

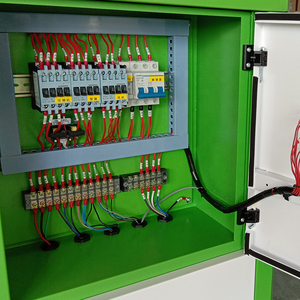

- Check the electrical components, including the contactor, relay, and circuit, to make sure the electrical connections are firm and there are no short circuits or exposed wires.

- Monitor the operating parameters of the chiller, including the pressure, temperature, power consumption, etc., and check and adjust them according to the manual to ensure that the chiller operates at the optimal performance level.

- Wrap the water pipes of the chiller with insulated covers to reduce energy loss and improve cooling efficiency.

Scenarios of brands chillers

-

F&B industry:

Whether it is a restaurant, bar, or any beverage-serving outlet, maintaining the taste and quality of drinks is essential. Brands chillers are preferred by many in the food and beverage industry to keep all the items fresh. Hence, branding chillers play a significant role in making that happen.

-

Designing firms:

Interior designing firms have a wide variety of projects to work on, such as hotels, restaurants, and shops, to name a few. Most of these places need showcasing products, and all needs a provided branding chiller to hold and show the products to customers while keeping them fresh.

-

Corporate offices:

Many corporate offices strive to make their employees feel good about the work environment. Hence, they include certain amenities like a cafeteria or pantry. In these places, a brands cooler can be used to serve chilled water bottles, soft drinks, etc. To keep the beverages cold and within reach.

-

Educational institutions:

Whether it's a school, college, or university, there are a lot of students who like to consume cold drinks, be it water, soda, or anything else. A brands chiller can be a great facility for them to have access to a variety of beverages. This can work as a sponsorship opportunity, and the institutes can collaborate with the beverage companies to place these coolers on their campuses.

-

Health clubs and gyms:

People visiting gyms and health clubs always look for chilled drinks, especially energy drinks and protein shakes. This is only possible if a firms advertise through branding chillers because those are the only machines that can hold a variety of drinks, and everything will be visible to the customer.

-

Public transportation services:

Brand chillers can be advertising opportunities for companies in the public transportation system, like buses, subways, and trains. They are placed in transit lounges and on vehicles to provide passengers with cold drinks, especially in hot weather. This can be an excellent advertisement opportunity for companies because many people will come across the branding.

How to Choose Chillers

When selecting a chiller, purchasers should consider different features of the machine, such as types, air-cooled chillers, features, efficiency and performance, sizes and capacities, operating environment, controls and monitoring systems, noise levels, safety standards, and compliance, etc.

- Chiller types: Businesses need to determine which type of chillers suits their needs. This will depend on various factors, such as the size of the company, the application used, etc. For example, if a business is small, it can opt for a portable chiller.

- Air-cooled condensers: Air-cooled chillers use ambient air for heat exchange. They are popular in commercial and industrial settings for various applications. Consider the benefits of air-cooled chillers, such as easy installation, low maintenance, space efficiency, etc. If these advantages align with the cooling needs and priorities, it is a good idea to choose an air-cooled chiller.

- Efficiency and performance: Opt for brands chillers that have high energy efficiency ratings. They help minimize operating costs by consuming less energy while delivering the required cooling capacity. Focus on the performance of a chiller, such as heat-exchange efficiency, temperature control, and reliability.

- Sizes and capacities: Consider both the physical size and cooling capacity of a chiller. It is essential to find a model that fits the available space and meets the cooling demands of the specific application.

- Operating environment: If a chiller will be installed in a harsh environment, like exposure to dust, humidity, or corrosive substances, it may need to choose a model with suitable components to cope with the conditions.

- Controls and monitoring systems: Modern chillers have advanced control and monitoring systems that allow precise temperature regulation, remote monitoring, data logging, and alarm functions. Consider these features for optimal system performance and maintenance.

- Noise levels: Chillers, especially air-cooled ones, can be noisy due to fans and compressors. Consider the noise levels of the chiller and choose one that meets the application's specific requirements.

- Safety standards and compliance: Ensure that the chiller complies with relevant safety standards and regulations. Check for certifications indicating adherence to specific safety and performance standards.

Q&A

Q1: How do air-cooled chillers differ from water-cooled chillers?

A1: Air-cooled chillers use ambient air for heat dissipation via air blower coils. On the other hand, water-cooled chillers use water or water-based fluids such as coolants for heat dissipation through condensers. Water-cooled chillers have superior cooling capacities. Air-cooled chillers are easier to install, while water-cooled chillers take up less space.

Q2: Are there any environmentally friendly chillers?

A2: Yes, some chillers use environmentally friendly refrigerants that have low global warming and ozone depletion potentials. Furthermore, some chiller brands incorporate energy recovery systems that reuse waste heat or opt for non-chemical technology such as electrolyzed salt water for cooling purposes.

Q3: How long do chiller machines last?

A3: Normally, a chiller machine can last for 15 to 20 years. Nevertheless, this lifespan can be shorter or longer, depending on factors such as the quality of the chiller, usage frequency and intensity, maintenance practices, and technological advancement. For instance, older machines can not support modern high-efficiency refrigerants.