Introduction to A234 Gr.B WPB

The A234 Gr.B WPB is a crucial component in the world of piping and plumbing systems. Recognized for its high-quality materials and robust performance under various conditions, this product meets the demands of demanding industrial applications. Commonly used as fittings, it provides reliable solutions in critical environments, ensuring the structural integrity of various systems. Whether you're in construction, oil and gas, or manufacturing, understanding the significance of A234 Gr.B WPB is vital for achieving optimal results.

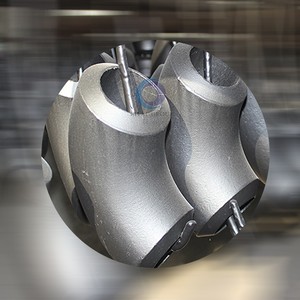

Types of A234 Gr.B WPB Fittings

A234 Gr.B WPB fittings come in various types, each designed to serve specific purposes within piping systems. The main types include:

- Elbows: Allow for directional changes in piping, typically available in 45-degree and 90-degree angles.

- Tees: Enable branching off from the main line into two additional directions.

- Reducers: Facilitate the connection of pipes of different diameters, allowing for efficient flow transition.

- Caps: Provide a seal on the end of piping systems, preventing leaks and contamination.

Applications of A234 Gr.B WPB

The versatility of A234 Gr.B WPB fittings makes them essential in numerous applications, including:

- Oil and Gas Industry: Commonly utilized in processing plants and refineries for transporting fluids and gases.

- Power Generation: Employed in steam generation systems where high temperatures and pressures are standard.

- Water Treatment Facilities: Used in piping for distributing treated water effectively within systems.

- Construction Projects: Integrated into HVAC systems for managing air conditioning and heating ducts.

Features and Advantages of A234 Gr.B WPB

The A234 Gr.B WPB fittings are designed with several key features that provide distinct advantages:

- Durability: Made from quality carbon steel, these fittings can withstand harsh environmental conditions, ensuring a longer lifecycle.

- Corrosion Resistance: Treatment processes enhance the material's ability to resist rust and other forms of corrosion, maintaining system integrity.

- High Temperature and Pressure Tolerance: Suitable for high-stress applications, these fittings excel in environments with extreme heat and pressure fluctuations.

- Easy to Install: Designed for straightforward installation, reducing labor costs and time delays on-site.