(2782 products available)

In conclusion, the 9.5mm pipe is used in different applications. Understanding the types and their uses will help industries choose the right one for their projects.

There are various functions of 9.5mm pipes in different industries that are critical for OEM and other business buyers to understand. They include:

They also have several features that influence their performance. These include:

The applications of 9.5mm pipes differ according to the material they are made of. For instance, copper pipes are used in plumbing, electrical wiring, and HVAC systems, while steel pipes are used in structural applications, fluid transmission, and construction projects.

Plumbing

PVC and copper pipes are commonly used in plumbing systems. Their applications include:

Water supply pipes: 9.5mm copper pipe is used to transport potable water to fixtures and fittings.

Drainage pipes: They are used to drain wastewater and sewage away from buildings.

Drainage and sewer pipes: These pipes carry wastewater away from buildings to treatment facilities.

HVAC

Copper pipes are commonly used in HVAC systems due to their thermal conductivity and corrosion resistance. Their applications include:

Refrigerant lines: 9.5mm copper pipe is used to transport refrigerants in air conditioning and refrigeration systems.

Condensate drains: They are used to carry the water produced by cooling systems away from the units.

Gas piping

9.5mm gas pipes transport natural gas or propane to appliances. Copper and steel pipes are preferred due to their durability and leak-proof characteristics. Gas pipes have a vital role in ensuring the safe delivery of gas to cooking and heating appliances.

Sprinkler systems

Copper and galvanized steel pipes are used in fire sprinkler systems. They are preferred due to their reliability and resistance to corrosion. The pipes provide a rapid and reliable response to fire incidents by delivering water to affected areas.

Oil piping

9.5mm copper pipe is used to transport oil in various applications. Their resistance to corrosion and ability to handle high pressures make them ideal for this use. They are commonly used in hydraulic systems, lubrication systems, and fuel oil distribution.

Electrical wiring

Copper pipes are also used in electrical wiring applications. Their high conductivity and corrosion resistance make them suitable for wiring installations. 9.5mm copper pipe is used in electrical distribution systems, lighting fixtures, and power outlets.

Recreational vehicles

9.5mm pipes are also used in recreational vehicles (RVs). Their light weight and compact size make them suitable for use in RVs. Additionally, they are used in water supply systems, electrical wiring, and gas piping in RVs.

Pressure Rating:

Pressure rating is critical when selecting a 9.5mm pipe for any application. This measurement indicates how much internal pressure the pipe can withstand safely. Different materials and wall thicknesses will have varying pressure ratings. For applications with higher pressure requirements, it is essential to choose a pipe with a suitable rating to prevent failures or leaks. On the other hand, lower pressure applications can use pipes with a rating that is not a concern. Considering the long-term pressure conditions, selecting a pipe material and size with an appropriate pressure rating is crucial for safety and functionality.

Fluid Medium:

Understanding the fluid medium is essential when choosing a pipe. Different fluids have unique properties, such as corrosive potential, temperature, and viscosity. These factors significantly influence how the fluid interacts with the pipe material. For instance, corrosive liquids require pipes made of resistant materials like HDPE or PVC, while high-temperature fluids demand heat-resistant options like copper pipes. Considering the fluid's characteristics ensures the selected pipe will withstand degradation and maintain optimal flow.

Length and Weight:

Considering the length and weight of a 9.5mm pipe is essential for efficient transportation and installation. Longer pipes may require special handling techniques during transport to prevent damage, while shorter sections are usually easier to handle and install. Additionally, the weight of the pipe influences the type of support structures needed during installation.

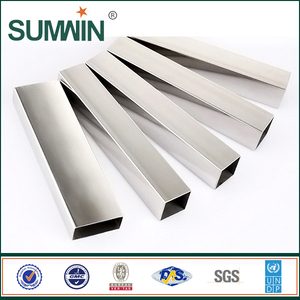

Material:

The first thing to consider when choosing a pipe is its material. Pipes are made from different materials, such as steel, copper, aluminum, and plastic. Steel pipes are widely used because they are durable and have a long lifespan. Copper pipes are also popular for carrying water in plumbing systems. Aluminum and plastic pipes are used in applications where weight reduction is essential.

Q: What does OD and NB mean in pipes?

A: NB means nominal bore, which is an approximate measure of the inside diameter. OD means outside diameter and is a more accurate way to measure the size of the pipe. For example, a 9.5mm pipe has an outside diameter of 9.5mm.

Q: How to measure a pipe size?

A: There are several ways to measure a pipe size. One can use a caliper to measure the outside diameter of the pipe. Then, use a tape measure to determine the wall thickness. Alternatively, one can use a pipe sizing chart that shows different pipes' nominal bore and outside diameter measurements.

Q: What is the difference between HDPE and PVC?

A: HDPE is more flexible than PVC, which makes it easier to install in underground applications. However, PVC becomes brittle at low temperatures, while HDPE has a wider temperature range. Additionally, HDPE is recycled more easily than PVC.

Q: What are the most common types of pipes used in construction?

A: Construction often uses PVC, copper, and steel pipes. PVC is popular for water supply and drainage because it is lightweight and easy to install. Copper pipes are used for water supply lines and plumbing because they are durable and resistant to corrosion. Steel pipes are used when high strength is required, such as in gas lines or structural applications.