(236 products available)

There are several types of 60s fusion splicers, and each is defined by the kind of fibers they accommodate. Accurate classification relies on various operational characteristics, including fusion splicing methods, automatic detection of oriented fibers, and the cleaving of the fibers. Below are some types of fusion splicers based on fiber core diameters, incorporating special features for additional functionality.

This splicer is primarily used for high-precision, low-power application fibers. These splicers are especially critical for applications involving data transmission over long distances, as even the smallest faults can cause significant attenuation.

As the name suggests, this fusion splicer can handle fibers with multiple cores. These play an important role in telecom for managing complex networks and supporting high bandwidth.

These splicers automatically adjust parameters for optimal splicing. They use sensors to control the alignment and heat application processes. This automatic functioning decreases the time frame needed for splicing and increases efficient results even when operated by less experienced staff.

These splicers require the operator to adjust alignment and other parameters. While these are mostly replaced by automatic models in the current scenario, they are still used in regions where power sources are not reliably available.

These devices provide the highest precision in fiber splicing. These splicers use cameras to align the fibers precisely. The fibers are aligned based on core positions using advanced imaging. This technology is crucial for maintaining signal integrity in high-performance.

These fusion splicers use grooves to align the fibers. The technician must manually place each fiber into a V-groove. Though not as precise as core alignment splicers, these splicers are commonly used.

Tweezers are most especially found in the telecom industry since it always requires precise and durable fiber optic splicing. Fusion splicers help in laying down broadband networks, telephone lines, and cellular networks. A 60s fusion splicer guarantees high precision and low signal loss in critical telecom operations.

Data centers rely on rapid and effective fiber optic networks for inside communication. Laying down long-distance networks for such high-speed domains need precise splicing performed with advanced tools like a fusion splicer. Such splicers allow quick and effective connections with minimal downtime.

In modern construction and infrastructure projects, splicers help integrate fiber optic cabling into buildings, bridges, and tunnels. It supports developing smart structures that employ an optic communication system. Practical and functional splicers are important in working within tight project deadlines while sustaining quality splicing.

Utilities companies employ fiber optics for communication and control systems. This is done within energy plants, grids, and pipeline systems. An S3 fusion splicer enables reliable and constant communication in critical operations within the energy sector. This is particularly important for visualizing the sclera and irises of the eyes with the help of an endoscope to monitor the fusion splicer.

Military applications require impervious and effective communication networks. The defense department relies on fusion splicers for laying down optic fibers in communication systems and surveillance networks. An S3 fusion splicer can operate in different environments with a reasonable level of splicing precision, making it suitable for military applications.

Precision Fiber Alignment

A 60s fusion splicer incorporates advanced core alignment systems that guarantee precision in aligning fibers, power saving, and low signal loss. Depending on the model applied, the alignment can be automated through imaging systems that minimize user intervention.

Quick Splicing Times

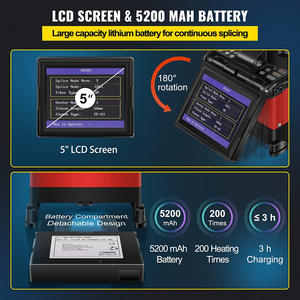

One of the important features of a fusion splicer is the speed of operation. The advanced splicers possess a heating and splicing capability within some seconds. Fast splicing time permits operation on larger volumes of splicers with efficiency.

Wind and Water Resistance

Modern splicers are made to be weatherproof fusion splicers that can withstand rain, snow, and wind. This attribute assists splicers to operate effectively in adverse working conditions.

Lanthanum Glass

Many splicer models use lanthanum glass for their electrodes. This glass has superior heat-retaining properties which lead to effective energy usage. This makes lanthanum fusion splicers both time-saving in operation and energy-efficient.

Proper use of a 60s fusion splicer is essential for best performance and splicing outcomes. Below are steps for optimal functioning:

A 60s fusion splicer should be properly conserved for effective long-term use. Below are important ways of conserving it:

Certainly, the kind of fusion splicer used for the wiring plays a large role in the outcome concerning quality when it comes to fiber optic splicing. A 60s fusion splicer is uniquely crafted for producing high-quality splices due to its properties and notable features. Below are important quality aspects:

Splice Loss Minimization

A good quality fusion splicer is needed for minimum splice loss. A 60s fusion splicer is created with core alignment systems that guarantee minimal loss of signals during the splicing process by properly aligning the fibers.

Precision and Accuracy

Precision is a requirement for the successful detection of fiber core diameters. The core alignment technology applied in the 60s fusion splicer enhances great precision over the splicing process. Misalignments lead to signal loss, which is avoided by using this equipment.

Consistent Results

Fusion splicer used in the making, in general, are incorporated with several automated features. These functions eliminate human-based errors in the fiber alignment and heat application process. Automated splicers achieve consistency, especially in mass production.

Safety is an important part of splicing fusion operations. Here are a few safety considerations regarding 60s fusion splicers:

Operating Procedures

The manufacturer of the fusion splicer must define all proper working procedures. Always follow these procedures for efficient working and for reducing the possibility of accidents.

Personal Protective Equipment (PPE)

PPE is important during the splicing process. These include gloves, goggles, and sometimes dust masks. PPE is important as it protects workers from potential hazards such as glass shards and equipment malfunctions.

Equipment Maintenance

Maintenance on 60s fusion splicers should be done regularly to enhance safety when operating this machine. A portion that is not maintained can malfunction during operation, producing dangerous results. Close and careful inspections of parts associated with electrodes and heating should be done routinely, and faulty components should be replaced immediately.

A1: Fusion splicing in fiber optics refers to joining two optical fibers by melting the ends together using an electric arc.

A2: A fusion splicer is used to precisely align and fuse two fiber optic strands, creating a permanent, low-loss connection.

A3: A fusion splicer first cleans and aligns the fibers, then uses an electric arc to melt the ends together, forming a tight connection.

A4: The benefits of fusion splicing are lower signal loss, better connection quality, greater precision, and lower attenuation compared to mechanical splicing.

A5: Fusion splicing uses an arc to melt fibers together for a permanent union with low loss, while mechanical splicing aligns fibers with a glue-like adhesive for a temporary connection that may result in slightly higher signal loss.

A6: In telecommunications, a fusion splicer is important for creating low-loss connections in large fiber optic networks for efficient, high-speed data transmission over long distances.