(5544 products available)

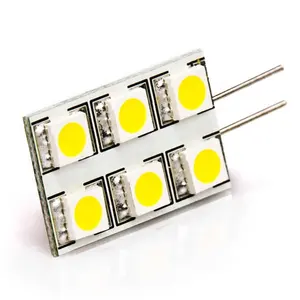

A 5w led pcb is a printed circuit board specifically designed for LED lighting applications. PCBs are fundamental components in electronic devices, providing a platform for mounting and electrically connecting electronic components. In the context of LED lighting, PCBs play a crucial role in dissipating heat generated by the LEDs and providing structural support. Here are the types:

Rigid LED PCB

Rigid LED PCBs are inflexible boards that provide a stable and flat surface for mounting LEDs. They are made from materials such as epoxy resin and fiberglass. The Rigid LED PCB is widely used in LED lighting applications because of its cost-effectiveness and simplicity in design. Rigid LED PCBs come in various sizes and designs and can be customized according to specific needs and requirements.

Flexible LED PCB

These are lightweight, thin, and bendable boards that can be bent and twisted into different shapes and sizes. Flexible LED PCBs are made from flexible substrates like polyimide or PET (Polyethylene Terephthalate) film. They are primarily used in applications where space is limited and components have to fit into tight or irregularly shaped spaces. Flexible LED PCBs are popular in backlighting for curved displays, wearable technology, and custom lighting fixtures.

Metal Core LED PCB

These PCBs are specifically designed for high-power LED applications where heat dissipation is crucial. They have a metal (usually aluminum) core that provides excellent thermal conductivity. Metal Core LED PCBs effectively dissipate heat away from the LED, ensuring optimal performance and longevity. They are commonly used in high-brightness LED applications, such as automotive lighting, high-bay lights, and LED streetlights.

Multilayer LED PCB

These PCBs have multiple layers of circuitry that allow for complex designs in compact form factors. They are used in advanced LED lighting applications that require high-density circuit configurations. Multilayer LED PCBs are found in high-end lighting solutions, such as LED displays, sophisticated automotive lighting systems, and intricate custom lighting installations.

High-Frequency LED PCB

High-frequency LED PCBs are designed to operate at high frequencies, making them suitable for specific lighting applications. They are used in LED lights that require high-frequency operation, such as certain types of strobe lights and RF (Radio Frequency) identification lighting.

LED PCBs are constantly evolving, and today's 5W LED PCBs are more efficient and powerful than ever. The following are some features of LED PCBs.

High Power

As the name suggests, a 5W LED PCB is designed to accommodate up to 5W of LEDs. This means that the LEDs on the board can have their power increased to 5 watts to produce higher brightness. Higher brightness is important in applications where visibility is required, such as in outdoor lighting, street lights, and automotive lighting.

Better Heat Dissipation

One of the major challenges of using LEDs is that they generate heat. If this heat is not properly managed, it can damage the LED and affect its performance. Fortunately, this 5W LED PCB comes with better heat dissipation features to counter this problem. For instance, it has a metal base, typically aluminum, which allows the heat to spread quickly and dissipate into the air.

Some PCBs also have copper heat sinks. The heat sinks increase the surface area from where the heat can dissipate, and as a result, the LED chip has a longer lifespan.

Compact Design

Today's lighting solutions demand PCBs that can fit in small spaces without compromising their performance. Luckily, the 5W LED PCB features compact design elements such as small-sized SMDs and multi-layer boards. As a result, these PCBs can be used in different applications, including portable devices and recessed lighting.

Versatile Applications

These PCBs can be used in different applications such as backlighting for LCD screens, general-purpose lighting, and decorative lighting. They are also used in outdoor lighting, automotive lighting, and high-bay industrial lighting. This versatility makes them a preferred choice for many lighting applications.

Improved Energy Efficiency

These PCBs are designed to work with low voltage and current. As a result, they consume less power, making them energy-efficient. The low power consumption makes these LED lights cheaper to operate and more environmentally friendly. In addition, they have a longer battery life when used in portable devices.

Improved Brightness

The 5W LED PCB operates at a higher output than most LED PCBs. This means that the LEDs on the board produce more light per unit of power consumed. In simple terms, these LEDs are much brighter and are perfect for applications that require high-intensity lighting, such as floodlights, high bay lights, and task lighting.

The use of 5W LED PCB lighting technology has greatly improved in recent years. This has made it more common in different industries and applications. The following are some of its usage scenarios;

Consumer Electronics

LEDs are commonly used in consumer devices like; smartphones, tablets, laptops, and digital cameras. In such devices, 5W LED PCBs are used for backlighting LCD screens and keyboard illumination. These LEDs provide energy efficiency and a longer lifespan. Additionally, they offer high brightness and customizable colors.

Automotive Lighting

Automotive manufacturers regularly use LED lighting technology in vehicles. The 5W LED PCBs are used for headlights, taillights, brake lights, indicators lights, interior lighting, and dashboard illumination. The LEDs provide enhanced visibility and safety. Also, they have a faster response time and a longer lifespan, improving the overall design of vehicles.

Outdoor Lighting

The LEDs are usually applied in outdoor lighting solutions. This includes; street lighting, parking lot lighting, architectural lighting, and landscape lighting. The 5W LED PCBs offer high luminous efficacy and low power consumption. This helps reduce energy costs and provide sustainable lighting solutions. Additionally, they provide high brightness and color rendering options for different outdoor settings.

General Lighting

The 5W LED PCBs are applied in various lighting products. This includes; LED bulbs, tubes, panels, and recessed lights. Here, they provide energy-efficient alternatives to traditional incandescent and fluorescent bulbs. The LEDs have a longer lifespan and a higher luminous efficacy. Therefore, they help reduce maintenance and replacement costs in commercial and residential settings.

Display Lighting

LEDs are widely used in display technologies such as LCD and OLED displays. The 5W LED PCBs are used for edge-lit and direct-lit backlighting in monitors, TVs, and digital signage. These LEDs offer high brightness, uniformity, and contrast ratio. This enhances the display's visibility, efficiency, and energy consumption. Additionally, the LED backlit displays consume less power and provide better color accuracy.

When choosing a 5W LED PCB, consider the following factors:

PCB Type

Metal Core PCB: A metal core LED light, usually aluminum, provides excellent heat dissipation. It is ideal for high-power LEDs like 5W LED lights. The aluminum core effectively transfers heat away from the LED, preventing damage and ensuring optimal brightness. Furthermore, the aluminum core is robust, offering physical protection to the LED components. It also promotes a longer lifespan for the 5W LED lights.

Flexible PCBs: If the lighting application demands bending or folding, consider a flexible PCB. They are made from flexible materials like polyimide, enabling the design to accommodate curves and angles. These PCBs are lightweight and space-saving, making them suitable for compact or intricate designs. They enhance the aesthetic appeal of the lighting solutions by allowing seamless integration into custom shapes and designs.

Number of LEDs

When considering the number of LEDs, understand that more LEDs provide greater brightness. A higher number of LEDs increases the total light output, making the space brighter. It is beneficial for applications requiring high illumination levels. Additionally, an increased LED count can result in a more uniform light distribution. More LEDs reduce the chances of hotspots or areas with excessive brightness compared to dimmer spots.

However, this depends on the LED positioning and design. More LEDs also enhance the visual appeal of the lighting. For example, in LED screens, more lights create vibrant and dynamic displays. However, increasing the number of LEDs also has drawbacks. It can lead to increased power consumption. Thus, the PCB design must balance the number of LEDs and the desired brightness to optimize these attributes.

LED Configuration

Series Configuration: In a series circuit, the LEDs are connected in a single path. It means the current flows through one LED and then to the next. This configuration ensures that all LEDs receive the same current, leading to uniform brightness. They also distribute the voltage drop across the LEDs. However, the main drawback of this configuration is that if one LED fails, the entire series strand goes out.

Parallel Configuration: Here, the LEDs are connected in multiple paths. Each LED has its path to the power source. The main advantage of this configuration is that the failure of one LED does not affect the others. Thus, the lighting fixture continues to operate, albeit at reduced brightness. Parallel configuration also allows for varying brightness levels among the LEDs.

Q1: What are the main components of a LED PCB?

A1: There are several key components of an LED PCB including; LEDs, resistors, which help in voltage regulation, capacitors, and traces. The metal core is usually used in high power LEDs.

Q2: What does a PCB LED light do?

A2: A PCB LED light helps to disperse heat generated by the LED chip. It does this by conducting heat away from the LED and dissipating it into the air. This helps to prevent overheating and ensures the LED chip functions optimally.

Q3: What does a 5W LED light bulb mean?

A3: A 5W LED light bulb means that the bulb uses 5 watts of power. LED bulbs are known to use less power compared to traditional bulbs. As such, a 5W LED bulb can produce the same amount of brightness as a 1520-watt incandescent bulb.

Q4: What does a 5W LED chip mean?

A4: A 5W LED chip means that the LED light uses 5 watts of power. A higher wattage indicates a brighter light. For instance, a 5W LED light chip can produce around 400-500 lumens. Lumens are a standard unit of measure for brightness.