(580 products available)

The two main types of disc filter are pressure filters and vacuum filters. The pressure disc filters are used in many industries because they can withstand high pressure. They are used for filtering slurries and wastewater in mining, paper making, and food processing. They are also used in seawater desalination to filter out salt and other impurities from the water. On the other hand, vacuum disc filters are commonly used in industries like pharmaceuticals and biotechnology where gentle handling of materials is important. They are used for filtering medicines and biological products.

50mm Pressure disc filter

A pressure disc filter works by passing the fluid to be filtered through a stack of filter discs under pressure. The pressure causes the fluid to flow through the pores of the filter material, while particles that are larger than the pores are trapped on the surface of the discs. The trapped particles build up on the surface of the discs and can be removed by backwashing.

50mm Vacuum disc filter

A vacuum disc filter creates a vacuum to draw the fluid through the filter discs. The vacuum pressure causes the fluid to pass through the filter discs, while particles are trapped and collected on the surface of the discs. The vacuum is usually produced using a vacuum pump.

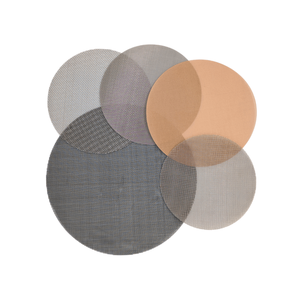

Material composition

The materials used to make the filter discs and other parts of the filter determine their strength, corrosion resistance and durability. Common materials include plastics, metals and ceramics. For example, stainless steel is strong and corrosion resistant, making it suitable for use in harsh environments. On the other hand, plastic materials are light in weight and resistant to chemicals and are therefore suitable for use in less corrosive environments.

Size and packing

The size of a disc filter refers to the diameter of the filter discs, which can range from 10mm to 200mm or more. The size of the discs and how they are packed together affect the filter's flow rate and filtration efficiency. Larger discs with wider spacing have higher flow rates but lower filtration efficiency, while smaller discs with closely packed discs have lower flow rates but higher filtration efficiency. The size and packing are therefore important considerations when selecting a disc filter for a particular application.

Disc filter components

Common components of disc filters include the filter discs, filter housing, inlet and outlet pipes, drive mechanism, and backwash system. The filter discs do the actual filtration, while the housing holds the discs and supports their structure. The inlet pipe carries the fluid to be filtered into the filter, and the outlet pipe carries the filtered fluid away. The drive mechanism moves the filter discs, and the backwash system removes trapped particles from the discs.

The design of the 50mm disc filters is made to ensure easy and effective filtration. They are easy to set up and use. They are small in size, so they are good for places with limited space. They are also good at removing dirt and other things from water. The design of the 50mm disc filters includes the following:

Agriculture Irrigation Systems:

Drip irrigation systems use disc filters to remove dirt and debris from the water. This keeps the small openings in the drip irrigation tubing clean so water can flow properly to plants. The disc filter provides water to crops efficiently by preventing clogs that could stop or slow down watering.

Green Roof Systems:

In a green roof system, disc filters clean the water that plants use from the roof. The filter takes out particles from rainwater or recycled water before it goes into the small tubes or porous materials that deliver water to the plant roots. This keeps the water supply clean for healthy plant growth.

Treatment Wetlands:

Constructed wetlands use disc filters to clean water flowing through them. The filter removes sand and dirt particles from the water before it moves slowly through the wetland plants. This keeps the water clean as it passes over the roots and soil. The disc filter plays an important role in removing suspended solids so the wetland can naturally treat the water.

Industrial Process Water:

Many industries use disc filters to clean their process water. For example, in metalworking, the filter removes metal shavings and particles from coolant fluids. In food processing, it filters out bits of fruits or vegetables from washing water. The disc filter keeps water clean so it does not contaminate products. This is important for maintaining quality standards in manufacturing.

Application Requirement:

Identifying the specific purpose of the filter is the first step in choosing the right one. Is it being used in irrigation systems, industrial processes, or water treatment facilities? Understanding the application will help determine what size and type of filter is needed.

Filtration Rating:

Filtration ratings indicate the size of particles that the filter can remove from the water. If small particle removal is essential, a filter with a tighter mesh should be chosen. For irrigation systems where larger particles do not clog emitters, a more extensive mesh may be sufficient.

Flow Rate:

The flow rate of water through the system should be considered when selecting a disc filter. A filter that restricts water flow too much will reduce system performance. Filters are rated for flow capacity, so matching the filter to the application’s needs is important.

Material and Durability:

Disc filters are made from various materials, including plastic, stainless steel, and bronze. Each material has advantages, such as corrosion resistance or cost-effectiveness. The filter's operating environment should be considered to choose a durable material.

Maintenance and Cleaning:

Disc filters can become clogged with debris and require cleaning to maintain performance. The ease of disassembling the filter for cleaning should be considered. Some disc filters also have backwashing capabilities, making them easier to maintain.

Q1: What is the purpose of a 50mm disc filter?

A1: The purpose of a 50mm disc filter is to remove impurities from fluids, thereby protecting equipment and enhancing system efficiency.

Q2: What are the components of a 50mm disc filter?

A2: A 50mm disc filter comprises filter discs, a housing, inlet and outlet ports, and a drain mechanism for collected debris.

Q3: How does a 50mm disc filter work?

A3: When fluid passes through the stacked filter discs, impurities are trapped in the spacing, creating filtered fluid that flows out through the outlet.

Q4: What materials are commonly used in 50mm disc filters?

A4: These filters are usually made from durable materials like polypropylene, stainless steel or bronze to withstand harsh fluids and corrosion.

Q5: What are the advantages of using a 50mm disc filter?

A5: The benefits include high dirt holding capacity, ease of maintenance, low pressure drop, modular design and versatility for various applications.