(371 products available)

There are many 3-way corner PVC fittings available for buyers to choose from, depending on the intended use. Some of the most common types are as follows:

3-way corner PVC Elbow

This type of PVC corner is often used for directing water through a corner in a piping system. It is called an elbow because it resembles a human elbow. PVC 3-way corner elbows are available in different angles, with the most common ones being 45 and 90 degrees.

3-way corner PVC Tee

This type of tee fitting has three openings; one on either side and one on top. PVC 3-way corner tees are used for connecting a branch line to a main piping line. PVC 3-way corner tees are often used in irrigation systems, water supply systems, and plumbing.

3-way corner PVC reducer

As the name suggests, this type of PVC corner fitting is used to connect two pipes of different diameters. The 3-way corner PVC reducer often has two openings; one is a smaller diameter and one larger to accommodate the smaller pipe.

3-way corner PVC crosses

They are very similar to PVC tees only that they have an additional opening at the bottom. A PVC cross fitting has four openings that are all on different ends. The 3-way corner PVC cross is used when it is necessary to connect four pipes, often intersecting at one point. They are mostly used in ventilation systems and irrigation systems.

3-way corner PVC caps

3-way corner PVC caps are fittings used to close off the end of a pipe. They are placed on the pipe's end to prevent any flow of water or air out of the pipe. PVC corner caps are often used in plumbing applications to terminate a branch line.

3-way corner PVC plugs

They are similar to PVC 3-way corner caps only that they are inserted into a fitting rather than placed over the external surface of the pipe. PVC 3-way corner plugs are used to clean or inspect a piping system. They are mostly used in irrigation systems and drainage systems.

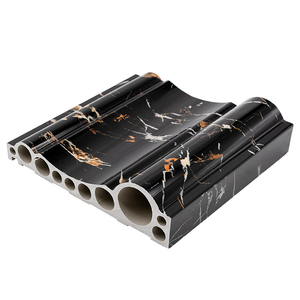

3-way corner PVC fittings

These fittings come in various types and sizes to meet different applications and needs. They are commonly used in construction projects, plumbing systems, electrical conduit installations, and irrigation systems.

Geometry

Each angle of a 3-way corner is 90 degrees, and each side should be measured to ensure that it will fit properly.

Size

3-way corners are available in a variety of sizes, which are described in terms of the size of the pipe they are intended to fit. For instance, a 3-inch corner is designed for pipes with a diameter of 3 inches.

Material

3-way corners are most commonly made of PVC, a material that is durable, corrosion-resistant, and affordable. They may also be made of other plastics.

Schedule

3-way corners are often classified by "schedule," which indicates the thickness of the walls. Schedule 40 corners have walls that are thick enough for most plumbing needs but are not as strong as schedule 80 corners, which have very thick walls. Corners with thicker walls are more suitable for high-pressure applications.

Connection Type

A 3-way corner PVC pipe fitting is available with different connection types. These include solvent-weld (glue), threaded, or slip connections. The type of connection will depend on the specific plumbing or piping system being used.

Color

3-way corner fittings are typically available in white or gray, the standard colors for PVC plumbing fittings. However, they may also be found in other colors for specialized applications or aesthetic preferences.

Pressure Rating

Some 3-way corners have a pressure rating, indicating the maximum pressure they can handle. This is especially important for plumbing systems with high-pressure water flow.

Temperature Tolerance

3-way corners have varying degrees of temperature tolerance, which makes them suitable for hot or cold water applications. If they are intended for hot water use, they will be able to withstand higher temperatures without deforming or weakening.

Application

3-way corners are used in various applications, including plumbing, irrigation, drainage, and industrial piping systems. Some fittings may be specially designed for specific industries or applications.

The following is a guide on how to take care of a 3-way corner PVC pipe:

Regular Inspection

It is important that the 3-way corner pipes should be inspected regularly to check for signs of wear, damage, or leakage. Early detection will make it easier to address problems before they worsen.

Cleaning

It is recommended that the corners be cleaned regularly to prevent the buildup of dirt or debris, which can clog pipes and reduce flow. Mild soap and water or specialized PVC cleaners can be used for cleaning.

Avoid Chemical Exposure

PVC pipes are resistant to many chemicals, but some harsh chemicals can cause damage over time. Avoid exposing the corners to these substances.

Pipe Support

For proper installation, the PVC pipe fittings should be supported along their length to prevent sagging and stress on the corners, which will reduce their lifespan.

Temperature Considerations

3-way corner pipes should be installed away from extreme heat or cold sources. Extreme temperatures can damage the PVC over time.

Avoid Overtightening

When 3-way corner fittings are being installed, it is important to avoid overtightening the joints, as this can cause cracking or deformation of the fitting.

Proper Jointing Techniques

If the 3-way corner fittings are being glued, the surfaces should be cleaned and primed. Then, a thin layer of PVC adhesive should be applied to each surface, and they should be held together for a few seconds until they are firmly bonded.

Protect from UV Exposure

Some PVC fittings can degrade over time when exposed to sunlight. If the corners are used outdoors, they should be coated with protective paint or a UV-resistant coating.

Monitor Flow

Water flow through the corners should be monitored. If there are any changes in the flow rate, it may indicate a blockage or damage that needs to be addressed.

There are several factors to consider when choosing the right 3-way corner PVC for any project. They include;

Consider the purpose of the corners

The intended use of the 3-way corner PVC fittings should be determined. Is it for plumbing, drainage, or electrical conduit? Each application has unique requirements and considerations.

Check the size and dimensions

Ensure the corners are of the right size and dimensions that suit the specific requirements of the project. This will allow for a proper fit and compatibility with the existing pipes or fittings.

Consider the material

Different materials are available in the market, such as PVC, CPVC, and ABS. Each material has its advantages and disadvantages based on the application. For example, PVC is the most common material used for plumbing pipes. This is because it is cost-effective and corrosion-resistant.

Consider the wall thickness

The wall thickness of the 3-way corner PVC fittings should be considered. Thicker walls offer more strength and durability. They are also suitable for applications that involve higher pressure or extreme environmental conditions.

Check for certifications and standards

The relevant industry standards and certifications should be checked for the 3-way corner PVC fittings. This ensures compliance with safety and reliability requirements. Some common certifications include ASTM, NSF, and UL.

Consider the cost

The cost of the 3-way corner PVC fittings should be compared from different suppliers. However, a budget should be prepared but do not compromise on quality. This is because the cheap fittings may not meet the project requirements and standards, leading to more costly repairs and replacements.

Check the availability

The availability of 3-way corner PVC fittings in the required sizes and specifications should be ensured. This will prevent delays in the project due to the inability to source the necessary fittings.

Consider the ease of installation

The ease of installation of the 3-way corner PVC fittings should be considered. Some fittings may require special tools or techniques, while others can be easily installed using standard methods. For example, fittings with solvent weld joints offer a reliable and durable connection but require the use of adhesives.

Check for warranties and guarantees

The 3-way corner PVC suppliers should offer warranties and guarantees for their products. This provides added assurance of quality and performance. If the corners do not perform as expected, they can be replaced.

Get recommendations

If unsure about which 3-way corner PVC fittings to choose, recommendations can be sought from professionals or experts in the relevant field. They can provide valuable insights and guidance based on their experience and knowledge.

Replacing 3-way corner PVC fittings can be a straightforward process, and it is something that can be done on a DIY basis. Here are the steps to follow:

Gather the necessary tools:

Make sure to wear safety glasses before beginning any work with PVC pipes. Cut out the damaged or worn-out fittings using a pipe cutter or hacksaw after measuring and marking the section of the pipe that needs replacement.

After removing the old fitting, clean the pipes' ends using a clean cloth to remove any debris or dirt. Before installing the new PVC 3-way corner fittings, use sandpaper or a deburring tool to smooth the pipe edges and remove any rough edges or burrs.

Use PVC primer to apply a coat to the outside of the pipes and the inside of the fittings. This prepares the surface for better adhesion and cleans the pipes. After the primer has dried, apply a generous amount of PVC cement to the pipes and fittings, making sure to cover the areas being joined.

Quickly insert the pipes into the fittings, ensuring they are properly aligned. Hold them in place for a few seconds to allow the cement to set. Wipe off any excess cement with a clean cloth before it dries.

Once the cement has cured, test the joints for leaks by turning on the water flow gradually. If any leaks are detected, reapply PVC cement to reinforce the joints.

Q1. Can someone paint 3-way corner PVC?

A1. Yes, a 3-way corner PVC can be painted. However, it is important to use a paint that is designed for plastic surfaces or to use a primer to help the paint adhere to the surface of the PVC.

Q2. Are 3-way corners PVC durable?

A2. Yes, the 3-way corners PVC are durable. They are made of strong and sturdy materials which makes them ideal for various applications. However, their durability may vary based on the specific type and application.

Q3. Can someone use 3-way corner PVC for outdoor purposes?

A3. Yes, PVC can be used for outdoor purposes. However, it is important to ensure that the specific type of PVC is designed for outdoor use and is resistant to UV radiation and other environmental factors.