(1543 products available)

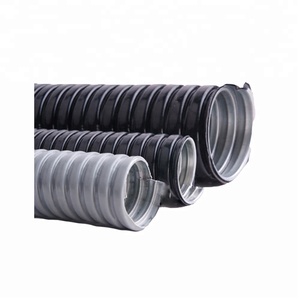

3 and 4 flexible conduit comes in different types. Here are some of them:

Steel flexible conduit

Steel flexible conduit features steel construction making ideal for heavy-duty protection. The material's rigidity affords enhanced electrical safety. In addition, this conduit is abrasion resistant hence useful in harsh environments. While it holds up well to physical stress, it is also heavier and less pliable compared to other flexible conduit types of conduits. Users prefer it for applications where increased protection and durability are essential.

Liquid-tight flexible conduit

This conduit offers protection against moisture and liquids due to its unique design. Made of metal or non-metal material, it features a seal at both ends. This seal prevents infiltration of water or chemicals. Users widely employ it in outdoor and industrial settings. These are places where exposure to elements is a concern. In addition, its flexibility allows for easy installation around tight bends and angles. This makes it adaptable for diverse application needs.

Non-metallic flexible conduit

A non-metal conduit contains PVC or other polymer materials. Its corrosion resistance properties make it ideal for environments with moisture and chemicals. In addition, this conduit is lightweight. This makes handling and installation easy. The non-metallic type is often used in outdoor applications and industrial settings. These are the ones where metal conduits might rust or corrode. While non-metallic conduits are generally more affordable, they are less durable under high mechanical stress.

Heli conduit

Heli conduit is a new innovative conduit that is applicable in many ways. It's a non-metal type of conduit. It's mainly used for the protection of electrical cables to ensure safe and reliable functioning. Made of high-quality materials, it provides good flexibility and durability. In addition, it's lightweight. This makes it easy to transport and install. Besides the outstanding resistance to corrosion and various chemicals, it's also a good heat and moisture barrier. This makes it suitable for outdoor and underground applications.

Flexible conduit with armor

Flexible conduit with armor adds an extra layer of protection to electrical wiring. The armor, usually made from steel, helps prevent damage to the conduit and wires inside from external hazards. This type of conduit is ideal for high-risk environments where exposure to mechanical stress, chemicals, or extreme temperatures is a concern. The flexibility of the conduit allows for easier installation in tight spaces. This is while the durable armor ensures the longevity and reliability of the electrical system.

3 flexible electrical conduits are manufactured with several materials. Here are some of them:

Galvanized steel

Galvanized steel is common in flexible conduits because of its excellent balance of strength and corrosion resistance. The zinc coating protects the steel from rusting. This allows the conduit to endure harsh environments including moisture and chemicals. Users appreciate its durability and flexibility, as it easily bends without breaking or kinking. These features make it ideal for enclosing and safeguarding electrical wiring.

Aluminum

Aluminum is a lightweight material for 3/4 conduit that offers flexibility and resistance to corrosion. Users prefer it when a conduit requires easy handling and installation in tight spaces. In addition, aluminum is non-magnetic and does not rust. This makes it suitable for both indoor and outdoor applications. Despite being lighter, the aluminum conduit still provides reliable protection for electrical wires.

Stainless steel

It features unmatched corrosion resistance compared to galvanized or aluminum steel types. Users prefer it in highly corrosive environments, such as chemical plants or coastal areas. Its durability extends not only against rust but also against mechanical damage. This makes it ideal for long-term applications where the utmost protection for electrical wiring is necessary. Although stainless steel is tougher, it comes with a higher cost.

Polymeric materials

Organic conduits come in lightweight and flexible materials such as polyethylene and PVC. Users value these non-metal options for their resistance to moisture, chemicals, and electromagnetic interference. In addition, these materials do not corrode. This makes them suitable for indoor and outdoor applications. Besides, their flexibility allows easy installation in tight spaces, accommodating complex wiring needs. Most importantly, they are more affordable compared to metal conduits.

Spiral lockseam

Spiral lockseam conduit, made of metal forms, features a distinctive spiral seam that enhances flexibility and durability. This design allows the conduit to bend without breaking or kinking. It's especially valuable in applications where frequent movement or vibration occurs. Users appreciate its strength and resistance to corrosion, particularly in industrial environments. In addition, it combines the resilience of metal with the adaptability needed for complex wiring routes.

Easy installation

The flexible nature of the conduit simplifies installation. It allows for easy routing around obstacles and through tight spaces. This reduces the need for multiple fittings and bends, resulting in lower labor costs and faster project completion times. In addition, its lightweight construction makes handling and transportation more convenient. Thus making it a cost-effective solution for contractors and businesses.

Versatility in applications

3/4 inch flexible metal conduit has a wide range of uses across different industries. These include electrical, construction, and mechanical fields. This adaptability makes it an attractive choice for businesses. They can utilize it in various projects without needing multiple conduit types. In addition, it effectively protects wiring in indoor, outdoor, and even industrial settings, further enhancing its commercial appeal.

Durability and longevity

Flexible conduit is designed to resist wear, corrosion, and exposure to different environmental elements. Such is the case with moisture and chemicals. Moreover, many types are rated for both outdoor and underground use. This ensures reliable protection even in extreme conditions. Users tend to favor durable products as they require less frequent replacements. This directly contributes to lower maintenance costs.

Safety and compliance

Flexible conduit provides not just protection but also grounding and shielding against electromagnetic interference (EMI). These features are critical for ensuring the safety of electrical systems. In addition, many flexible conduits meet or exceed industry standards and regulations. These may be UL or NEC. Thus, using this conduit helps companies avoid potential fines or liabilities. This enhances their reputation as a business adhering to safety protocols.

Increasing demand for electrical installations

The rapid growth in construction and infrastructure projects drives demand for flexible conduit. This is especially in an era where electrical systems become more complex. Flexible conduit offers the adaptability and ease of installation required in such evolving electrical needs. It thus presents significant growth opportunities for businesses engaged in electrical and construction work.

Cost

The cost of the conduit will greatly impact the choice. Non-metallic flexible conduits are cheaper than metallic ones. This makes them appealing to buyers on a budget. The price of the conduit is usually affected by raw material as well as its place of origin. Buyers will also consider bulk orders to get discounts when buying straight from a manufacturer.

Durability

The durability of a conduit greatly affects the choice. Buyers will look for conduits that have durable exteriors that can withstand extreme temperatures. Such types have ratings that indicate the range of temperatures the conduit can endure. They will also check for abrasion resistance as it indicates stronger materials which will last longer. In addition, they will check for nematodes resistant to chemicals and moisture to ensure the conduit lasts longer in damp areas.

Installation ease

Buyers will consider conductors that have a flexible nature. These make the installation process easy, especially in tighter spaces. Additionally, they will check for conduits that possess smooth interiors to minimize friction. This makes electrical wiring easy. Buyers will also consider conduits that do not require many tools or additional fittings for quicker installations.

Specific applications

Buyers will choose flexible conduits based on certain applications. For instance, conduits with an additional protective layer metal in non-armored conduits are ideal for individuals dealing with potential metals. Those dealing with external mechanical damage will go for conduits with armor as they provide extra protection. Buyers who deal with conditions that may involve immersion in water will opt for liquid-tight flexible conduits.

Conduit size

Conduit size is an important factor since the right size ensures compatibility with electrical cables. Buyers will check the conduit’s inner diameter so that it can accommodate the total number of cables. Furthermore, they will choose various sizes of conduit to give sufficient space for the cable insulation. Size and space will also act as a safeguard against overheating of the cables.

Here are some common questions that buyers might ask:

What is the purpose of flexible conduit?

A flexible conduit is used to protect electrical wires. This is due to its flexibility; the conduit can be easily maneuvered in tight spaces, around obstacles, or even along surfaces that are uneven. This makes it particularly useful in both residential and commercial construction. In addition, the conduit provides a durable shield against mechanical damage, moisture, and chemical exposure, helping to ensure the safety and longevity of electrical systems.

What are the benefits of flexible conduit?

One key benefit is its flexibility, which makes installations in tight or awkward spaces much easier and quicker. It also offers excellent protection against mechanical damage, moisture, and chemical exposure. This is especially in harsher environments. Flexible conduit is generally lighter than rigid conduit, thus easier to handle and install. Besides, it adapts well to moving parts or vibrations. This makes it ideal for use in machinery or equipment applications. Lastly, it provides a cost-effective solution for various wiring needs.

Is flexible conduit water resistant?

Yes, flexible conduit is designed to offer a degree of water resistance. The level of water resistance, however, largely depends on the type of flexible conduit chosen. Liquid-tight flexible conduit, for instance, is specifically designed to prevent water and moisture from entering. This makes it ideal for outdoor use and wet locations. Other types, like PVC or metal flexible conduit, also offer some level of resistance to moisture and corrosion.

How long does flexible conduit last?

Flexible conduit is built to last for many years. The lifespan typically ranges from about 10 to 30 years. This depends on several factors such as the type of material. It also depends on the environment and the level of mechanical stress it endures. For instance, liquid-tight or non-metallic conduits often have a lifespan of around 20-30 years in normal conditions. Most importantly, flexible conduits maintain their protective qualities if properly installed and are regularly maintained. This ensures they safeguard the electrical wiring system for the duration of their lifespan.

Can flexible conduit be installed underground?

Flexible conduit can be installed underground, but several considerations must be made for a successful underground installation. Buyers will go for liquid-tight flexible conduit and non-metallic are the best options for underground applications. This is due to their moisture and chemical resistance. Buyers should also ensure the conduit is properly sealed at both ends to prevent the infiltration of water or soil particles. They should also use a compatible underground junction box. This will bolster protection for the electrical connections.