(711 products available)

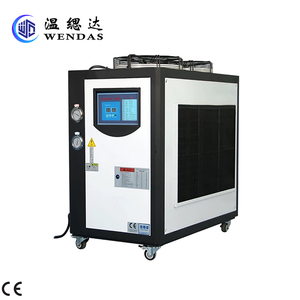

A 25hp chiller provides a precise temperature control and is a crucial component of a cooling system. Industrial chillers generally remain outdoors and are connected to a huge system that can provide cool water or fluid to an entire manufacturing process.

Air-cooled industrial chillers directly use the air around them to disperse heat from refrigerant gas in their coils.

A/C Chillers:

An air conditioning chiller uses either absorption or vapor-compression refrigeration processes to cool air. In absorption chillers, heat is used to drive cooling, often employing Lithium Bromide or Water as the refrigerant. Vapor-compression chillers, common in residential and industrial settings, rely on electricity to function, using refrigerants like R-410A or R-22.

Process Chillers:

Process chillers are designed to play a critical role in industrial factories where precise temperature control is crucial. Factories may need to cool machinery, chemical reactions, and high-precision equipment like lasers and injection molding machines. A consistent temperature can prevent unwanted fluctuations to ensure product quality and optimal machinery efficiency. Unlike A/C chillers, which cool air, a 25-hp water chiller for processing facilities cools water or other liquids. These might be utilized to cool down cutting equipment in a factory that produces metal, for example, so that they can continue to function well even under the strain of high levels of activity.

Modular Chillers:

Modular chillers offer scalable cooling solutions by adding or removing modules to meet changing demands. Their flexible design adapts to varying needs while maintaining efficiency.

Air-cooled industrial chillers typically have heat exchangers, condenser fans, compressors, and evaporators. To dissipate heat into the air, industrial air cooler chillers use its condensers and cooling fans. The job of the compressor in a chiller, which is typically produced at 25 horsepower to 30 horsepower, is to pump the refrigerant gas and modify the pressure to regulate how much heat must be extracted. By absorbing heat from the coolant, an evaporator operates as a heat exchanger, keeping the substance inside it cool. Industrial chillers that are water-cooled employ cooling towers instead of air to remove heat from the surrounding environment.

Some of the key specifications of the 25hp water chiller are as follows:

Temperature Range

25hp chillers are available in different temperature models. The working temperature range is-10°/15° to 20°/25° (±1°). The full temperature models range from-10° to 25°.

Refrigerant:

The 25hp water chiller uses R-22, R-407C, R-410A, and other green refrigerants that meet international environmental standards.

Heat Exchange:

It uses a shell-and-tube type condenser and evaporator for heat exchange. This kind of heat exchanger has high efficiency, excellent performance, and a long service life, which can meet different needs. Its applicable pressure is up to 3.2MPA.

Noise:

Its operating noise level is usually below 90 decibels, which belongs to the high-efficiency and low-noise chiller in the industry. In addition, the 25hp water chiller is more tranquil when running at night due to its silent mode.

Dimensions:

Dimension details vary depending on the 25hp chiller type: a water-cooled chiller, an air-cooled chiller, or a portable chiller. The average dimension is Length*Width*Height=1890*860*1380mm.

Net Weight:

A 25hp air-cooled chiller unit weighs approximately 625kg, while a water-cooled counterpart weighs about 835kg. The higher net weight of the water-cooled chiller is due to the tanks that refrigerate the water.

Temperature control:

Microcomputer control technology is applied to the chiller, so it can automatically adjust the working state according to the load. It can accurately control the outlet chilled water temperature within ±1 degree.

Intelligent system:

An intelligent system is equipped with a 25hp air chiller. The working state of the chiller will be automatically analyzed, and the fault will be diagnosed and displayed for the user to check quickly.

During the usage of the water chiller, it is crucial to carry out proper maintenance and keep the equipment in a good state. Here are some maintenance tips for the 25hp water chiller:

Regular Cleaning

Regularly clean the air-cooled condensers, evaporators, and fans on the chillers using high-pressured air or water. The same applies to the water-cooled chillers' water and air tanks, tubes, cooling towers, and pumps. Regularly cleaned components prevent dirt and scaling that affect heat exchange and the system from breaking down.

Replace Filters:

Replace the water filter in the water tank regularly to avoid impurities affecting the performance of the chiller. Replace the air-cooled chiller's compressor and refrigerant filters to prevent clogging and affect refrigerant circulation.

Lubrication:

Regularly lubricate each revolving part of the chiller, such as its motor, fan, and pumps. Lubricants with excellent anti-wear and heat-resistant properties should be selected to keep the bearings and sealing components in the cooling system functioning well and not get damaged.

Inspect Cooling Water:

If it's a water-cooled chiller, regularly inspect the cooling water quality and adjust its chemical dosage so as to prevent the corrosion and scaling of cooling system parts.

Daily Check:

Daily check of the chilled water temperature, inlet and outlet water, refrigerant pressure, operating current, and other parameters is essential. It helps to ensure the normal operation of the chiller. Users should also monitor the system alarm codes, check the components' working status, and deal with any potential risks in a timely manner to ensure the safety and stability of the chiller system.

25hp industrial water chillers have different applications in various industries. Here are some examples of their usage.

Food and Beverage Industry

A brewery in the food and beverage industry uses a 25hp air cooled chiller to maintain the ideal fermentation temperature. The fermenter needs to stay within a certain temperature range for the brewery to produce high-quality beer. Other equipment in the brewery that can use a chiller is the keg cooler, serving tank cooler, and flash pasteurizer.

Medical Facilities

Hospitals and medical facilities may use a 25hp chiller for different applications. For one, they can use it to keep ambient temperatures cool in some sensitive medical equipment like MRI machines. These machines work optimally when the temperature is within a specific range. Chillers can also be used to cool down blood plasma, medicines, and other medical liquids. Additionally, they can be used to maintain cool temperatures in laboratory facilities.

Data Centers

A data center undertaking server farming may consider using a 25hp water chiller to keep the servers cool. The chillers provide a constant flow of cooled water to the cooling coils of the facility's air management system. The air management system helps to maintain safe operating temperatures for the servers.

Machining and Manufacturing

Manufacturing and machining facilities use a 25hp chiller for a variety of purposes. One common use is to cool cutting fluids and oils to ensure they remain effective even when the temperature changes. Another use of the chiller is to cool or freeze plastic molds quickly when manufacturing plastic products. A cooler mold will help to increase production speed and reduce production costs.

Laser Cutting and Engraving Machines

A 25 hp laser chiller can be used to cool down lasers in cutting and engraving machines. These lasers generate a lot of heat during operation. A water chiller can help to reduce the heat and maintain optimal laser performance.

Agriculture

Farmers can also use a 25hp chiller to support agricultural processes. One example is the cooling of hydroponic nutrient solutions. Chillers can also be used to cool livestock housing and greenhouses.

When buying a 25 hp chiller for business purposes, it is important to consider factors such as the system design, ecological footprint, energy efficiency, application, capacity, resale value, and future needs.

Q1: What is the difference between a water-cooled chiller and an air-cooled chiller?

A1: A water-cooled chiller uses water to dissipate heat from the refrigerant, typically utilizing cooling towers or evaporative condensers. On the other hand, an air-cooled chiller relies on ambient air, often through finned-tube condensers and integrated fans, to release heat from the refrigerant.

Q2: What does "hp" mean in a chiller's description?

A2: "Hp" refers to horsepower, a unit of measurement used to describe the power output of motors driving chillers. It indicates the size and cooling capacity of the chiller, with one horsepower equivalent to 0.746 kilowatts.

Q3: How does a chiller deal with heat transfer?

A3: The chiller absorbs heat from the substance or space to be cooled through the evaporation of refrigerant gas. Then, it removes that heat through the condensing process, releasing it to the environment, while the refrigerant is cycled back to start the process again.

Q4: Are 25hp chillers expensive?

A4: The cost of 25hp chillers depends on many factors, including the type, brand, capacity, features, efficiency, and market conditions. Generally, larger and more powerful chillers tend to be more expensive due to their capacity and complexity.