(120 products available)

A 120hp chiller is a large-capacity cooling system commonly used in industrial and commercial facilities. It is designed to remove heat from a liquid through a vapor-compression or vapor-absorption refrigeration cycle. 120hp chillers are available in various types, including air-cooled chillers, water-cooled chillers, flooded chillers, and screw chillers.

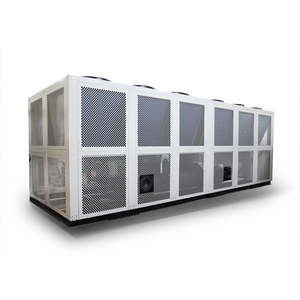

Air-cooled chiller

An air-cooled chiller is a refrigeration system that uses the air around it for cooling purposes. Within the chiller system are external condenser coils that dissipate heat into the atmosphere. Fans blow ambient air across the coils to facilitate this process. Because of this method of heat elimination, air-cooled chillers do not require additional water for operation and instead rely solely on ambient air. Due to their self-contained quick installation and low maintenance needs, air-cooled chillers are excellent for small to medium-sized applications or places where water cooling is impractical.

Water-cooled chiller

Water-cooled chillers use water as the cooling medium instead of air, making them suitable for high-capacity refrigeration needs. Water-cooled chillers exist in the form of tube ice storage or evaporative cooling. They are typically more energy-efficient than air-cooled chillers. Firstly, in tube ice storage, water is frozen into ice, which absorbs heat as it melts, providing cooling. In contrast, evaporative cooling relies on water from the cooling tower to conduct heat away, evaporating in the process. Water-cooled chillers are preferred in applications where space is at a premium and heat rejection to water can occur.

Flooded chiller

A flooded chiller is a specific type of water-cooled chiller. In it, refrigerant flows into the evaporator, where heat is absorbed from the water used for cooling. The evaporator is filled with refrigerant, which absorbs heat by cooling water; the circulating water maintains a level within the evaporator, making it less vulnerable to heat exchange systems and more efficient. Because they have a high capacity and efficiency, flooded chillers are frequently utilized in large buildings, facilities, or industrial settings.

Screw chiller

Screw chillers use a volumetric compression principle. They utilize twin-screw compressors that compress the refrigerant to remove heat from the liquids. Because of their simple structure, ease of operation, high reliability, and low failure rate, screw chillers are appropriate for large-scale cold demand. When it comes to energy efficiency, they have superior performance, high COP (Coefficient of Performance), and EER (Energy Efficiency Ratio).

The performance of chillers is determined by various specifications. They include the cooling capacity, compressor types, refrigerants, voltage, and amperage, among others.

120hp water chillers are suitable for both commercial and industrial buildings. The term "Horse Power" represents how well the chiller will perform. 1 ton is equivalent to 12 Horse Powers. Therefore, a chiller with 120 Horse Powers will perform a function equivalent to 120/12 = 10 tons.

Ongoing chiller maintenance is crucial for both performance and efficiency. Regular inspections should be scheduled for the chiller. With time, some components like the condenser may get too dirty, which may affect how the chiller functions. During inspections, more frequent tasks like checking the fluid levels and coolant levels should be done.

More maintenance tips include monitoring the chiller's performance. Owners should be keen on changes in the performance of the chiller. If any settings or factors change, they should be investigated immediately to avoid any potential problems.

Lubrication of moving components should not be overlooked. Chillers have many parts that can wear out over time if they are not oiled regularly, affecting the overall performance. Finally, maintaining the required temperature and pressure is crucial for a chiller to function properly. Regular inspections should be scheduled to ensure that these two factors are ideal and that there are no underlying issues.

A 120hp chiller is suitable for large-scale commercial applications, industrial production, and big buildings.

Food and Beverage Industry

In the food and beverage industry, 120hp chillers are used for food preservation, brewing, and other applications that require low-temperature processing.

Pharmaceutical and chemical industry

120hp chillers are widely used in the pharmaceutical and chemical industries for the cooling of chemical reactions, equipment, and production lines and for ensuring product quality and compliance with standards.

Large building central air conditioning

120hp chillers are applied in the central air conditioning systems of large buildings such as hotels, shopping malls, office buildings, and more. They provide cool water for air conditioning to ensure the comfort of the interior space.

Data centers and server farms

120hp chillers are essential for cooling equipment in data centers and server farms. They help maintain an optimal operating temperature to ensure the stability and reliability of computer systems.

Plastic processing

In the plastic processing industry, 120hp chillers are used to cool injection molding machines and other equipment. They help improve production efficiency and maintain the quality of plastic products.

Printing and dyeing factories

120hp chillers play a crucial role in cooling printing presses, dyeing machines, and other equipment in printing and dyeing factories. They help regulate the temperature and ensure the quality of printed and dyed products.

Rubber processing

Rubber processing companies utilize 120hp chillers to cool rubber processing machines, vulcanization presses, and other equipment. They assist in enhancing production efficiency and guaranteeing the quality of rubber products.

When purchasing a large chiller, such as a 120hp chiller, buyers should consider various factors. First, the cooling capacity of the chiller is important. Chillers are available in a variety of sizes and cooling capacities. If the size is too small, the chiller may not be able to sufficiently lower the temperature of the confined space. On the other hand, if it is too big, it may consume excess energy, which will increase operating costs.

Next, buyers should take the energy efficiency of the 120hp chillers into consideration. Chiller efficiency is usually rated by the coefficient of performance (COP) or energy efficiency ratio (EER). The higher the COP or EER is, the more energy-efficient the chiller will be, leading to lower operating costs.

Also, the refrigerant type and pressure should be taken into consideration. Buyers should choose chillers with refrigerants that comply with local environmental regulations and make sure they have the appropriate handling and storage procedures if the refrigerant is in high pressure.

In addition, the 120hp chiller’s design and construction are paramount. Buyers should choose chillers with durable materials and reliable construction so that they can have a long lifespan. Furthermore, it is important for business buyers to consider whether the chiller is easy to maintain and service since regular maintenance is necessary to keep the performance of the chiller.

Finally, buyers are suggested to choose reputable manufacturers and suppliers so as to ensure the long-term availability of spare parts and support service. Doing extensive research and reading reviews from other users can also be helpful.

Q1: What does 120hp mean in a chiller?

A1: The ''hp'' in the chiller stands for horsepower. In this case, it represents the size or capacity of the chiller. Chiller capacity is usually measured in horsepower, tons, or kilowatts.120 hp chiller is equivalent to approximately 14.3 tons or 47.4 kilowatts of cooling power.

Q2: What are the differences between air-cooled and water-cooled 120hp chillers?

A2: The main difference between the two chillers is how they dissipate heat. An air-cooled chiller uses ambient air from the environment to reject heat. It needs the natural flow of air, which makes it compact and convenient to use. On the other hand, water-cooled chillers use water to reject heat. It requires water and additional equipment such as cooling towers and pumps. Water-cooled chillers are suitable for large industrial applications.

Q3: How long can a 120hp chiller run continuously?

A3: There is no exact answer to the question. The actual run time depends on some factors, like maintenance, operating conditions, load demands, and design.

Q4: Can a 120hp chiller be used in different applications?

A4: Yes, a 120hp chiller can be used in different applications. It can be used for cold storage, food processing, chemical processing, plastics, pharmaceuticals, data centers, and more.